Method of recycling flucytosine chlorination wastewater

A technology of chlorinated wastewater and flucytosine, which is applied in chemical instruments and methods, natural water treatment, extracted water/sewage treatment, etc., can solve the problem of no recycling system for chlorinated wastewater, increased production costs of enterprises, and impact on the surrounding environment, etc. problems, to achieve the effect of reducing production water consumption and wastewater discharge, reducing treatment costs and improving economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A method for recycling flucytosine chlorinated waste water, which comprises the following process steps: take 30 kg of waste water from the production line of flucytosine chlorination, send the above waste water into a chlorinated waste water treatment kettle, and open the waste water treatment still Stirring, the stirring speed is 180rpm, after cooling down to 10-20°C, continue to stir and add 20% calcium hydroxide solution dropwise, adjust the pH value to 9.0-10, filter through a filter, and filter to obtain phosphate solids and filter waste water. Filtration waste water is sent to chlorinated waste water extracting and washing tank, adds 2.4kg toluene and carries out extracting and washing 2 times, layering, and wherein upper strata is organic layer, and lower floor is water layer, and the hydrochloric acid solution that water layer is 8% with mass concentration is adjusted to pH is 6.5-7.5, 25kg of water is obtained after treatment, and the recovery rate is 83.3%. Th...

example 2

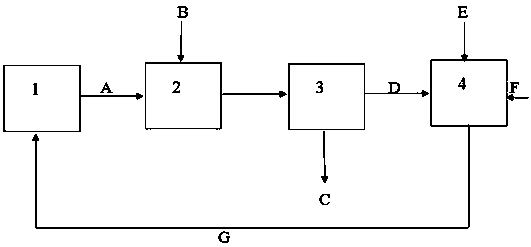

[0016] Such as figure 1 Shown, a kind of method for flucytosine chlorination waste water recycling, it comprises the following process steps: get waste water 50kg from the production industrial line of flucytosine chlorination, above-mentioned waste water is sent in the chlorination waste water treatment still, open Stir the wastewater treatment tank with a stirring speed of 180rpm. After cooling down to 10-15°C, continue to stir and add 20% calcium hydroxide solution dropwise to adjust the pH value to 9.0-10. Filter through a filter to obtain phosphate solids and filter Wastewater, the filtered waste water is sent to the extraction and washing kettle of chlorinated wastewater, and 4.5kg of toluene is added to carry out extraction and washing for 2 times, layered, wherein the upper layer is an organic layer, and the lower layer is an aqueous layer, and the aqueous layer is adjusted with a hydrochloric acid solution with a mass concentration of 8%. When the pH is 6.5-7.5, 42kg ...

example 3

[0018] Such as figure 1 Shown, a kind of method for flucytosine chlorination waste water recycling, it comprises the following process steps: get waste water 50kg from the production industrial line of flucytosine chlorination, above-mentioned waste water is sent in the chlorination waste water treatment still, open Stir the wastewater treatment tank at a stirring speed of 180rpm. After cooling down to 15-20°C, continue to stir and add 20% calcium hydroxide solution dropwise to adjust the pH value to 9.0-10. Filter through a filter to obtain phosphate solids and filter Wastewater, the filtered waste water is sent to the extraction and washing kettle of chlorinated wastewater, and 5.0kg toluene is added to extract and wash 3 times, and the layers are layered, wherein the upper layer is an organic layer, and the lower layer is an aqueous layer, and the aqueous layer is adjusted with a hydrochloric acid solution with a mass concentration of 8%. When the pH is 6.5-7.5, 41kg of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com