Preparation method of modified anhydride curing agent for extending applicability of epoxy resin system

A technology of epoxy resin system and acid anhydride curing agent, applied in the chemical industry, can solve the problems of short applicability of epoxy resin, and achieve the effect of solving short applicability and prolonging applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

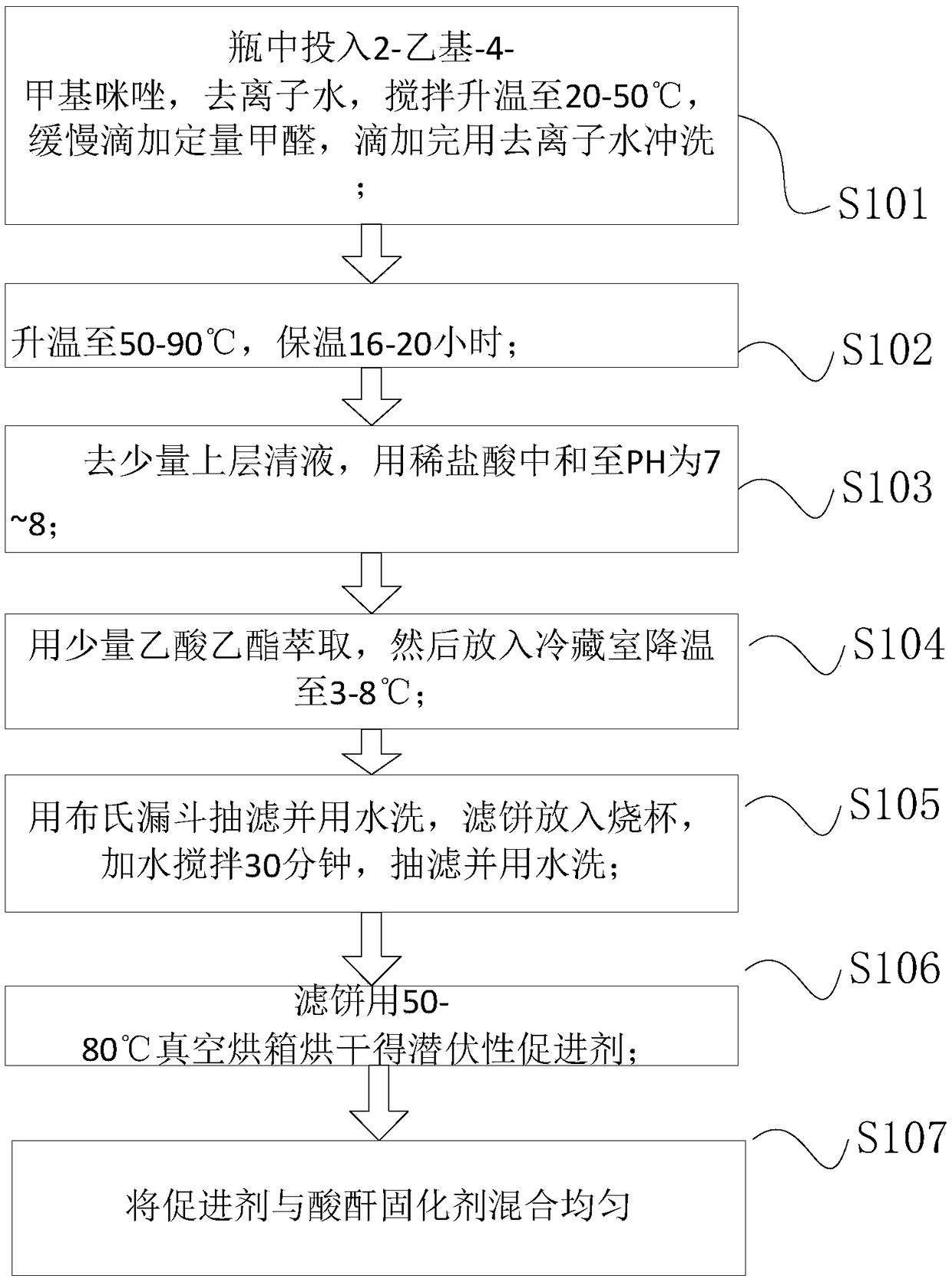

[0030] See figure 1 , A method for preparing a modified acid anhydride curing agent for extending the applicability of an epoxy resin system, comprising the following steps:

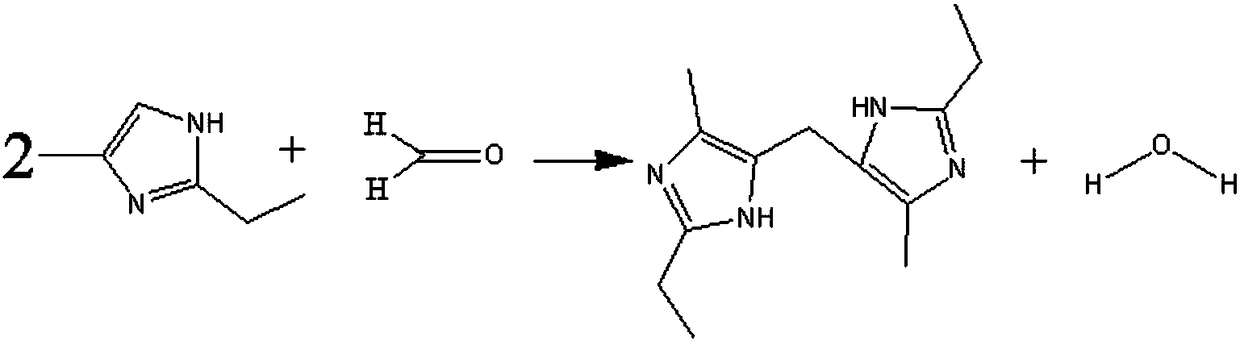

[0031] S101: Put 2-ethyl-4-methylimidazole and deionized water into the bottle, stir and raise the temperature to 20-50°C. Slowly add quantitative formaldehyde, rinse with deionized water after the addition;

[0032] S102: Raise the temperature to 60-90°C and keep it for 16-20 hours;

[0033] S103: Remove a small amount of supernatant liquid, and neutralize with dilute hydrochloric acid to a pH of 7-8;

[0034] S104: Extract with a small amount of ethyl acetate, and then put it in the refrigerator to cool to 3-8°C;

[0035] S105: Filter with Buchner funnel and wash with water, put the filter cake into a beaker, add water and stir for 20-50 minutes, filter with suction and wash with water;

[0036] S106: The filter cake is dried in a vacuum oven at 50-80°C to obtain a latent accelerator;

[0037] S107: Mix the acce...

Embodiment 1

[0041] Example 1: Put 2-ethyl-4-methylimidazole and deionized water into the bottle, stir and raise the temperature to 20-50°C. Slowly add quantitative formaldehyde, rinse with deionized water after dripping; the ratio of 2-ethyl-4-methylimidazole to deionized water is 590:33, the ratio of 2-ethyl-4-methylimidazole to formaldehyde Between 2 / 3 and 1 / 3.

[0042] Warm up to 70℃ for 16-20 hours; remove a small amount of supernatant, neutralize with dilute hydrochloric acid to a pH of 7-8; extract with a small amount of ethyl acetate, then put it in the refrigerator to cool to 5℃; use a Buchner funnel Filter with suction and wash with water, put the filter cake in a beaker, add water and stir for 30 minutes, filter and wash with water; the filter cake is dried in a vacuum oven at 60°C to obtain a latent accelerator; the accelerator and acid anhydride curing agent are evenly mixed.

Embodiment 2

[0043] Example 2: Put 2-ethyl-4-methylimidazole and deionized water into the bottle, stir and raise the temperature to 20-50°C. Slowly add quantitative formaldehyde, rinse with deionized water after dripping; the ratio of 2-ethyl-4-methylimidazole to deionized water is 590:33, the ratio of 2-ethyl-4-methylimidazole to formaldehyde 33:19.2.

[0044] Warm up to 70℃ for 16-20 hours; remove a small amount of supernatant, neutralize with dilute hydrochloric acid to a pH of 7-8; extract with a small amount of ethyl acetate, then put it in the refrigerator to cool to 5℃; use a Buchner funnel Filter with suction and wash with water, put the filter cake in a beaker, add water and stir for 30 minutes, filter and wash with water; the filter cake is dried in a vacuum oven at 60°C to obtain a latent accelerator; the accelerator and acid anhydride curing agent are evenly mixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com