PSC light thermal insulation and decoration structure integrated prefabricated outer wall board and preparation method thereof

A technology for decorative structures and exterior wall panels, applied in chemical instruments and methods, thermal insulation, walls, etc., can solve the problems of increasing production costs, occupying building area, and the weight of external wall panels, reducing the difficulty and cost of hoisting, and achieving good thermal insulation. And sound insulation performance, good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

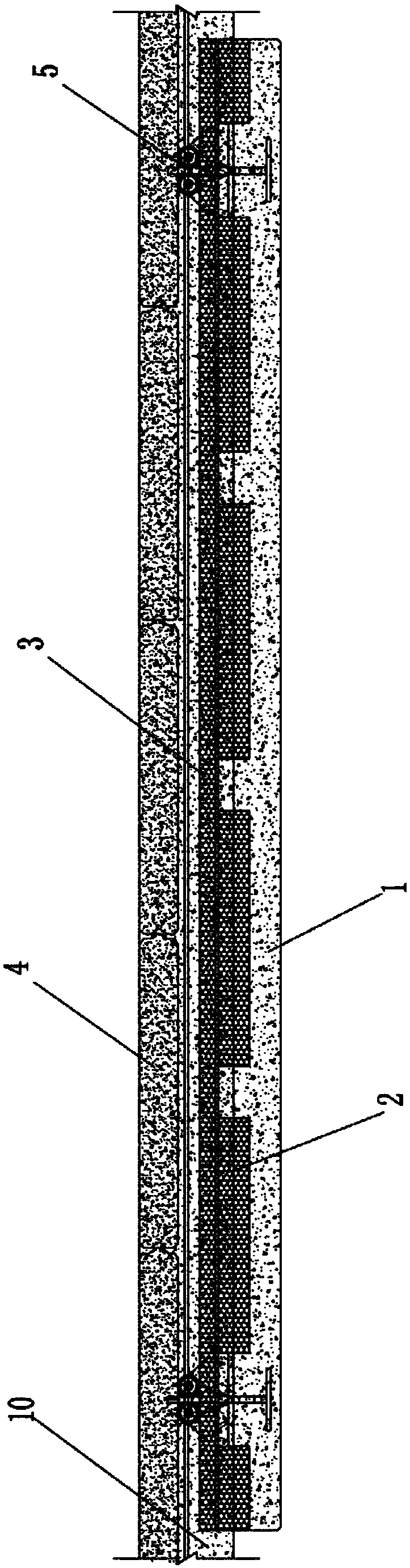

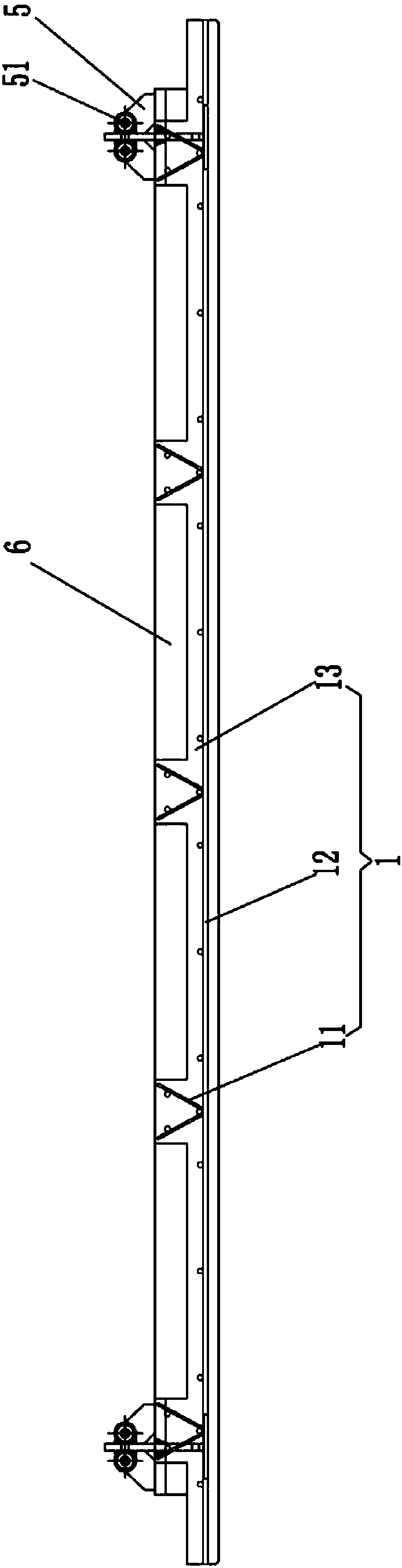

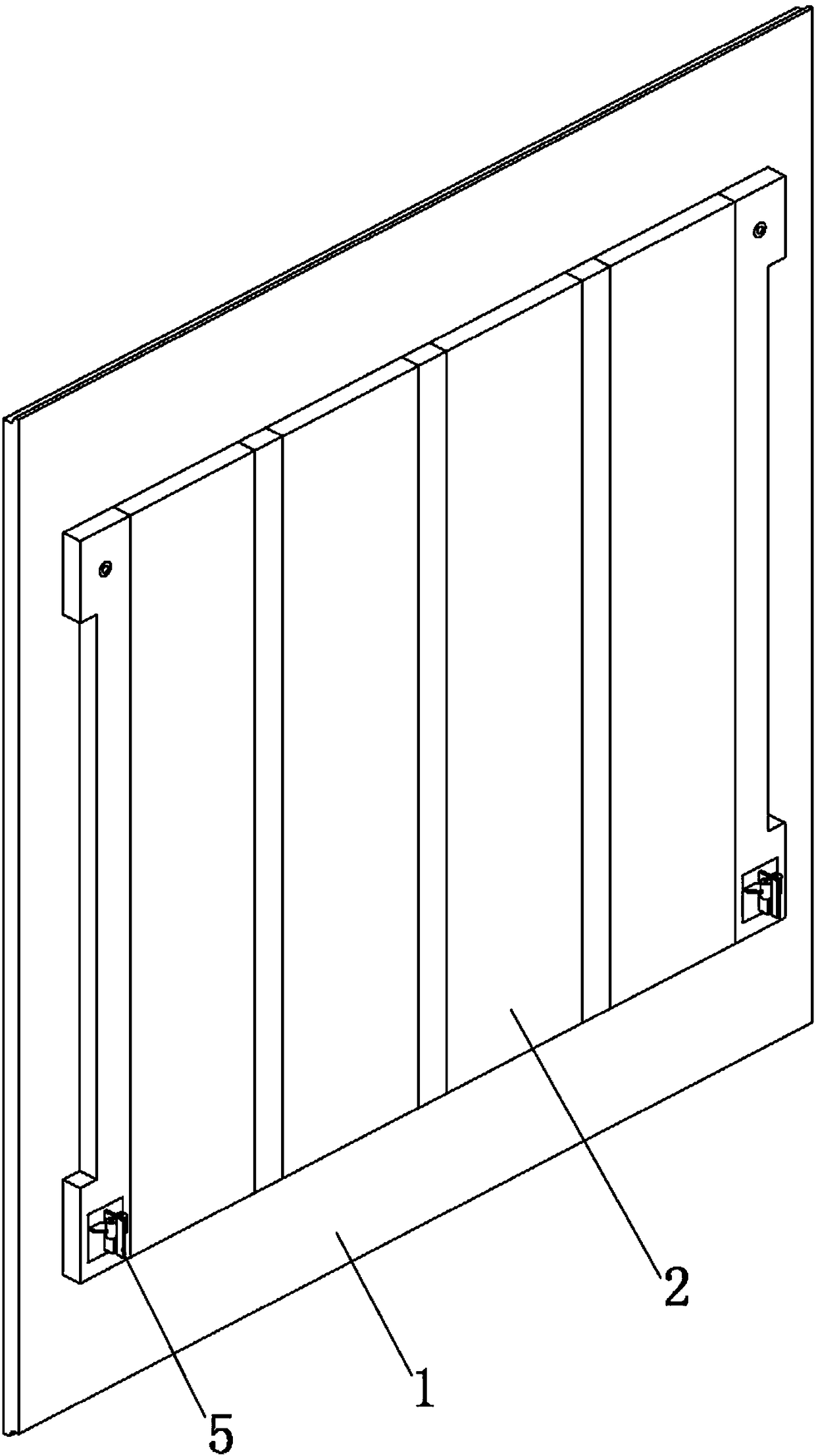

[0036] Please refer to the attached figure 1 to attach Figure 4 As shown, the present invention is an integrated prefabricated exterior wall panel of a PSC light-duty thermal insulation and decoration structure, which can be hung on the main load-bearing structure 10. Concrete, Autoclaved Lightweight Concrete) board 4 and other parts.

[0037] Wherein, the outer surface of the ribbed panel 1 is painted and shaped by the factory to achieve the effect of integrated decoration. A pre-embedded hanger 5 is pre-embedded on the ribbed panel 1 . The pre-embedded hanger 5 is hung on the main load-bearing structure 10 , so that the ribbed panel 1 is hung on the main load-bearing structure 10 .

[0038] Specifically, the embedded hanger 5 is composed of a base 51 , an embedded plate 52 , a hanging plate 53 , a reinforcing plate 56 , and adjusting bolts 54 . Wherein, the base 51 is welded on one side of the embedded plate 52, which is embedded in the ribbed panel 1; the hanging plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com