Piston of heavy oil engine and aero-engine

An engine and piston technology, applied in the direction of engine components, machines/engines, pistons, etc., can solve the problems of insufficient combustion, inability to mix uniformly, engine power, economy and emission performance cannot be achieved, and achieve smooth drainage effect. The effect of reducing the risk of knocking and improving the guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

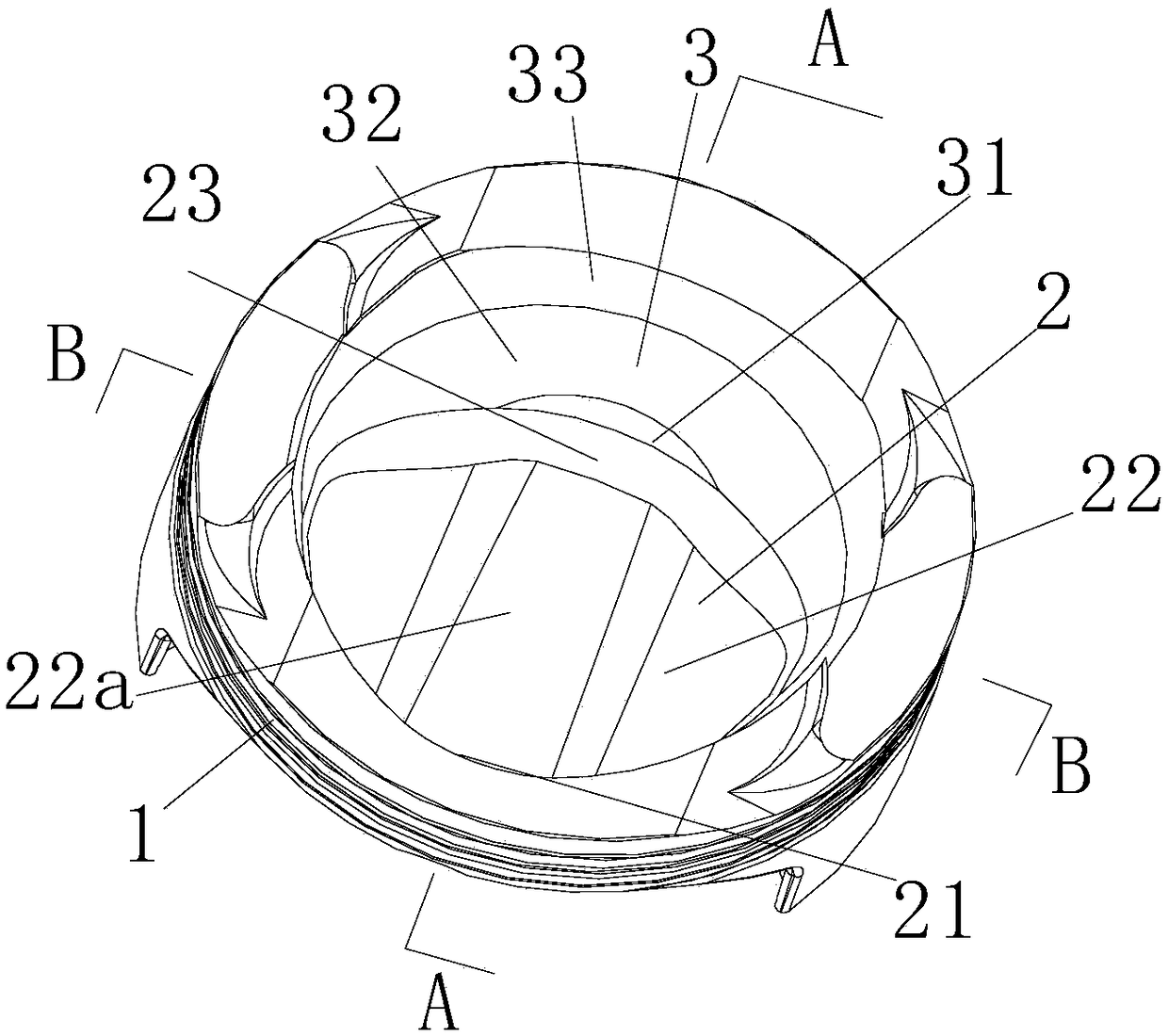

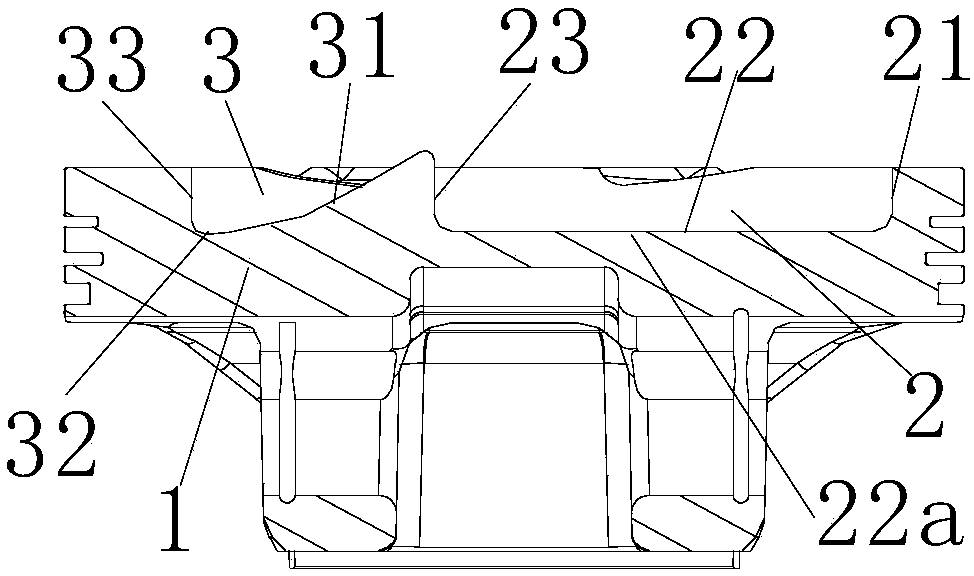

[0024] As shown in the figure: the heavy oil engine piston of this embodiment, the structure of the present invention used in the engine is shown in the figure, the engine includes a cylinder block 5, a cylinder head 13 and a piston assembly, as shown in the figure, the piston 1 of the piston assembly is located in the cylinder Inside the body 5; the cylinder head is provided with a fuel injection assembly that injects fuel into the combustion chamber;

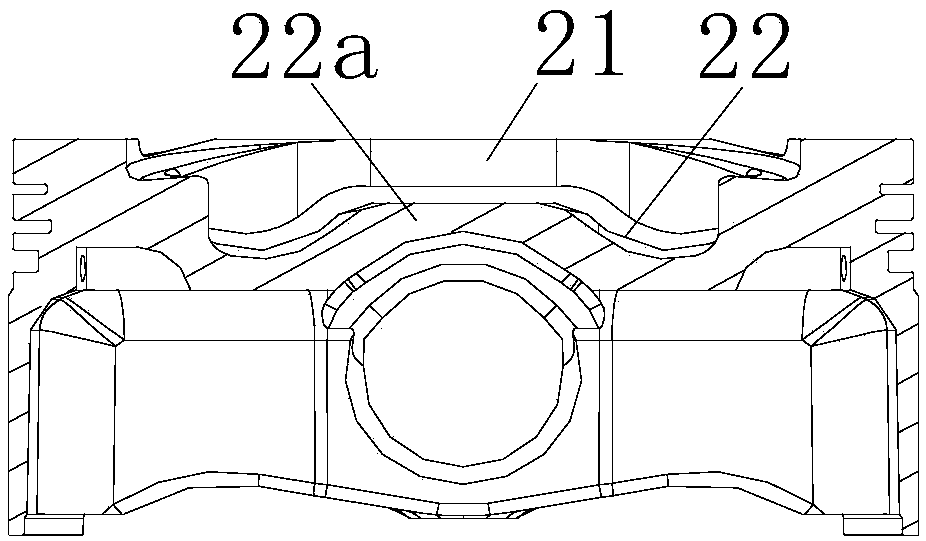

[0025] The top surface of the piston 1 forms a concave guide portion 2 that is sunken relative to the top surface of the piston; the concave guide portion 2 corresponds to the fuel injection direction of the fuel injection assembly, and includes an outer surface that transitions smoothly from outside to inside in the radial direction 21. The bottom 22 and the outlet surface 23, the outermost point of the outer surface 21 in the radial direction exceeds or is parallel to the fuel injection direction (referring to when the fuel a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com