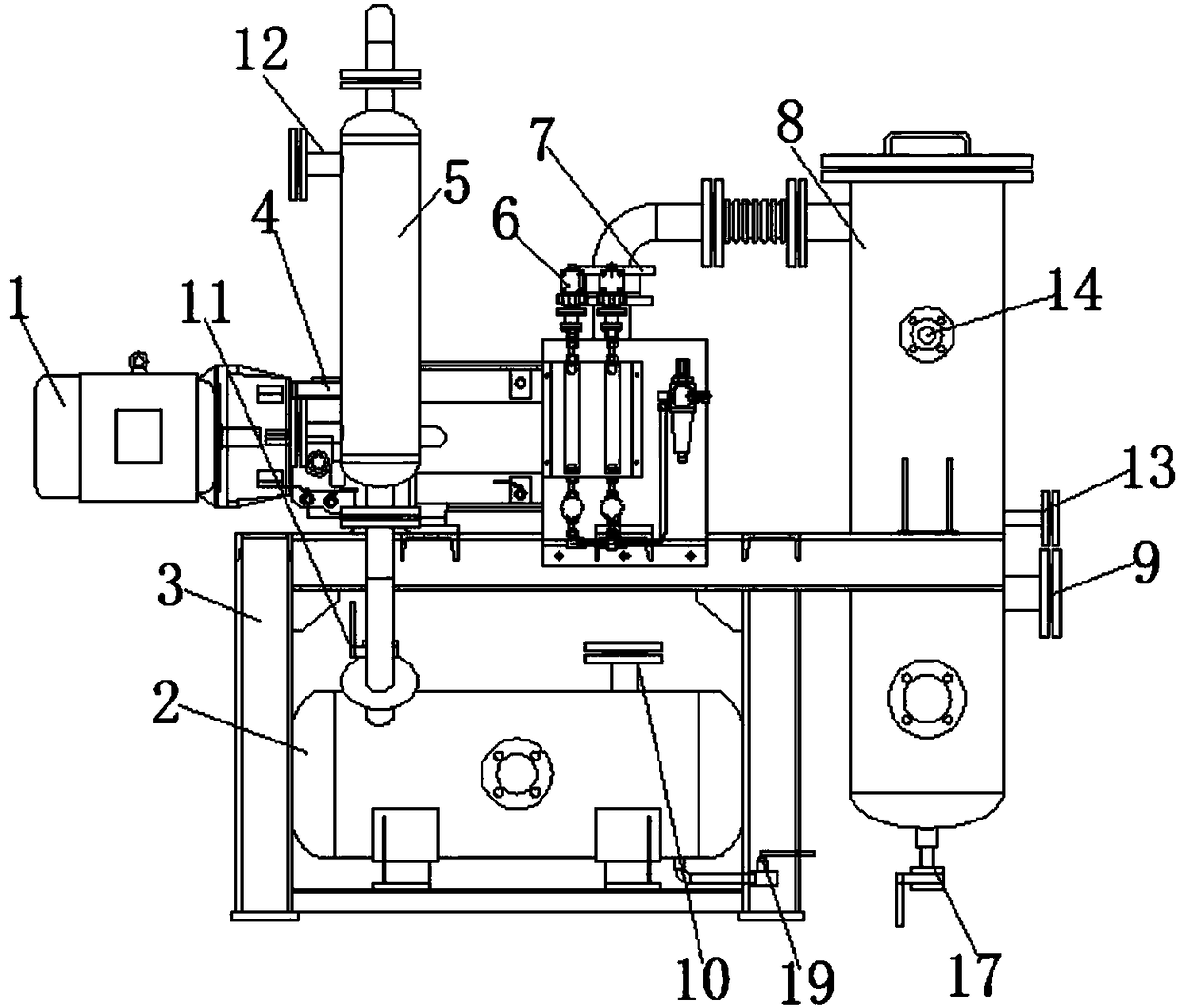

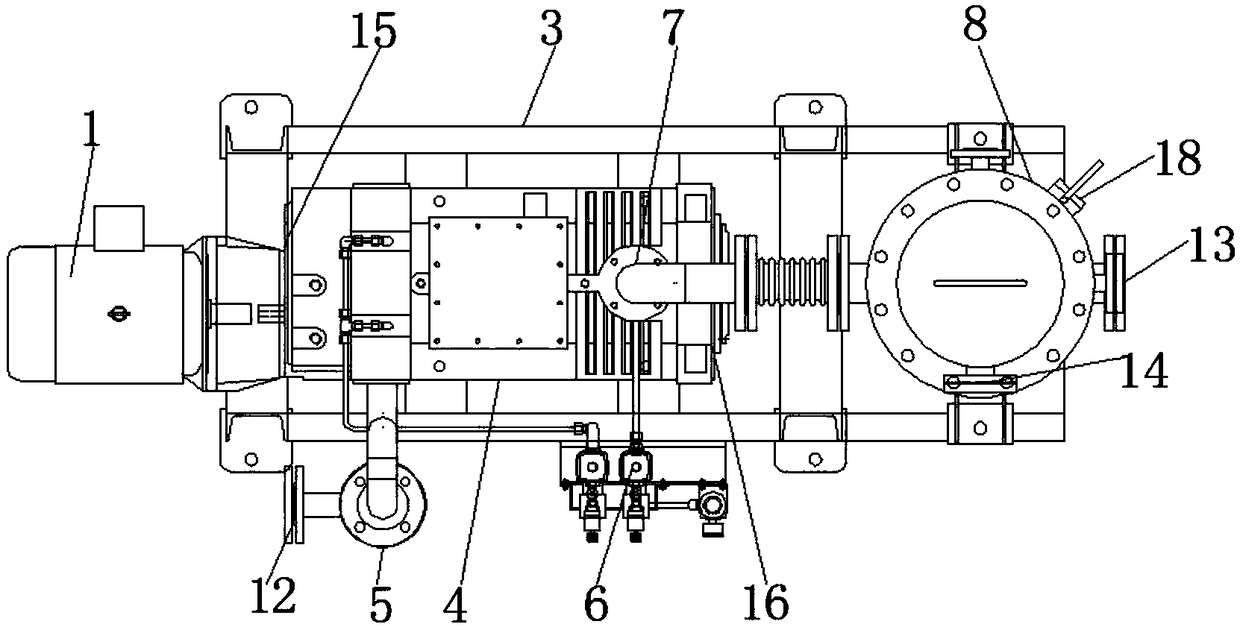

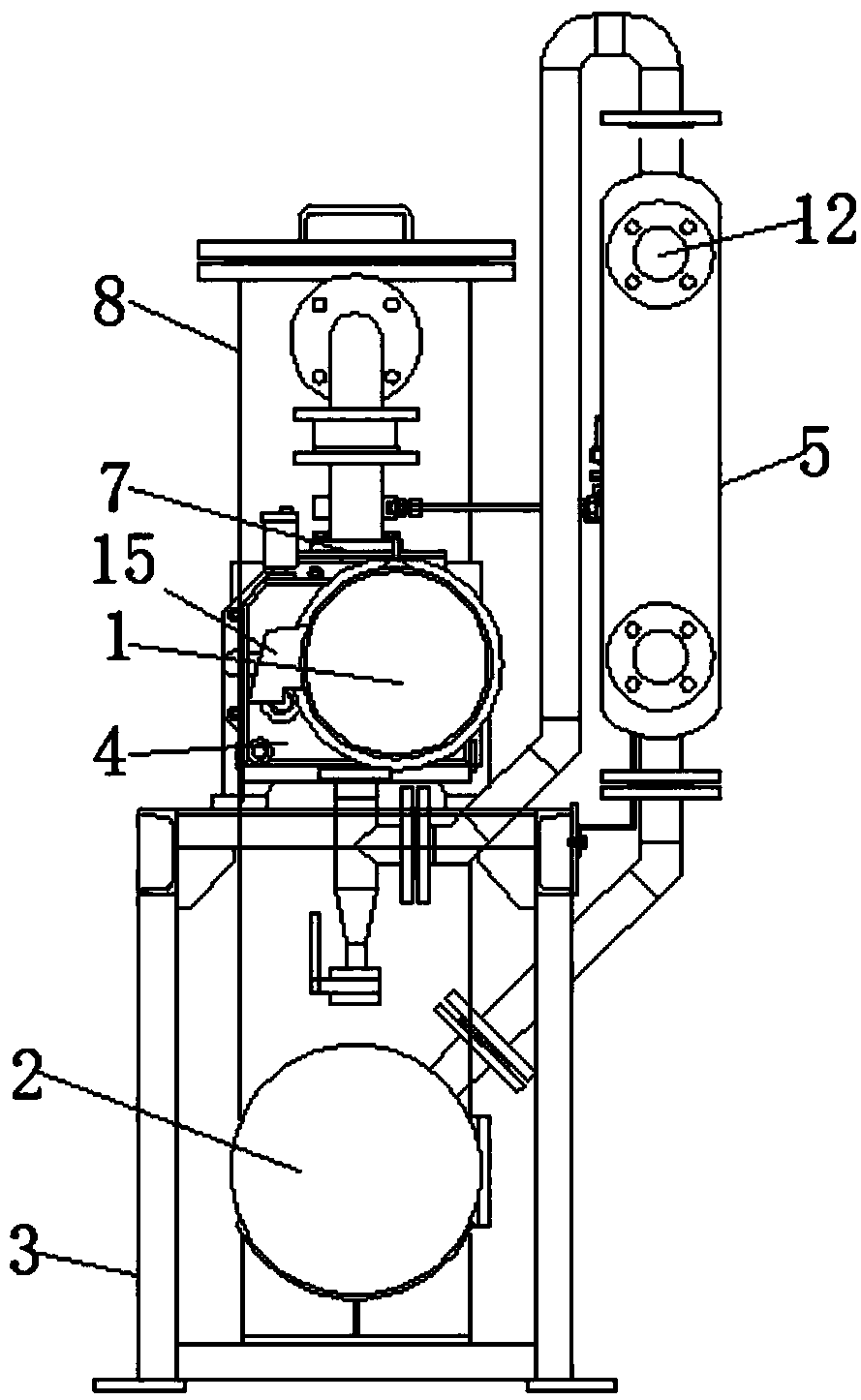

Dry type vacuum unit for solvent recycling

A vacuum unit and solvent technology, applied in the direction of rotary piston machinery, mechanical equipment, machine/engine, etc., can solve the problems of high power consumption, non-compliance with energy saving requirements, low efficiency, etc., to achieve compact structure, convenient installation, and improved economical effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0020] Embodiment: The pumped gas containing the solvent is sucked by the screw vacuum pump 4 and first enters the inside of the filter 8 with condensation recovery function from the air inlet 9, so as to cool down the pumped gas and filter dust, and the cooled and filtered The gas to be pumped is sucked, compressed, and transported into the wound tube condenser 5 through the screw vacuum pump 4, and the condensed and liquefied solvent flows into the recovery tank 2 for storage, and the non-condensable gas is discharged through the exhaust port 10 on the recovery tank 2 system, the recovered solvent is recovered through the second solvent discharge port 19, thereby effectively reducing solvent pollution, reducing solvent consumption, and improving the economic benefits of pharmaceutical companies.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com