A combined quick-freezing device based on flat jet impingement evaporator

A jet impact and quick-freezing device technology, which is applied in the direction of compressors with multiple evaporators, evaporators/condensers, cooling fluid circulation devices, etc., can solve the problem of intermittent production of quick-frozen food thickness, large heat transfer coefficient, Low quick-freezing speed and other problems, to achieve the effect of shortening quick-freezing time, enhancing heat transfer coefficient, increasing evaporation temperature and cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

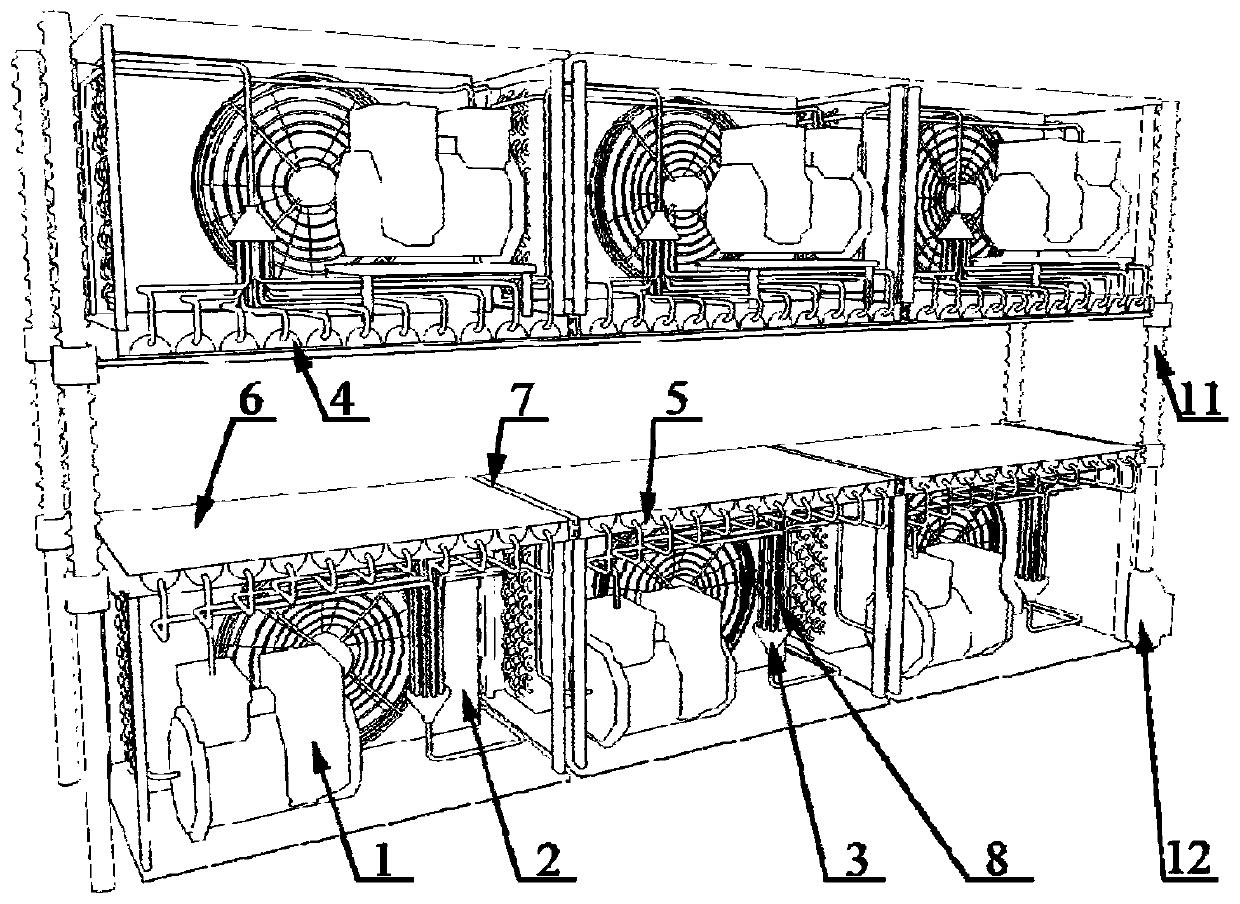

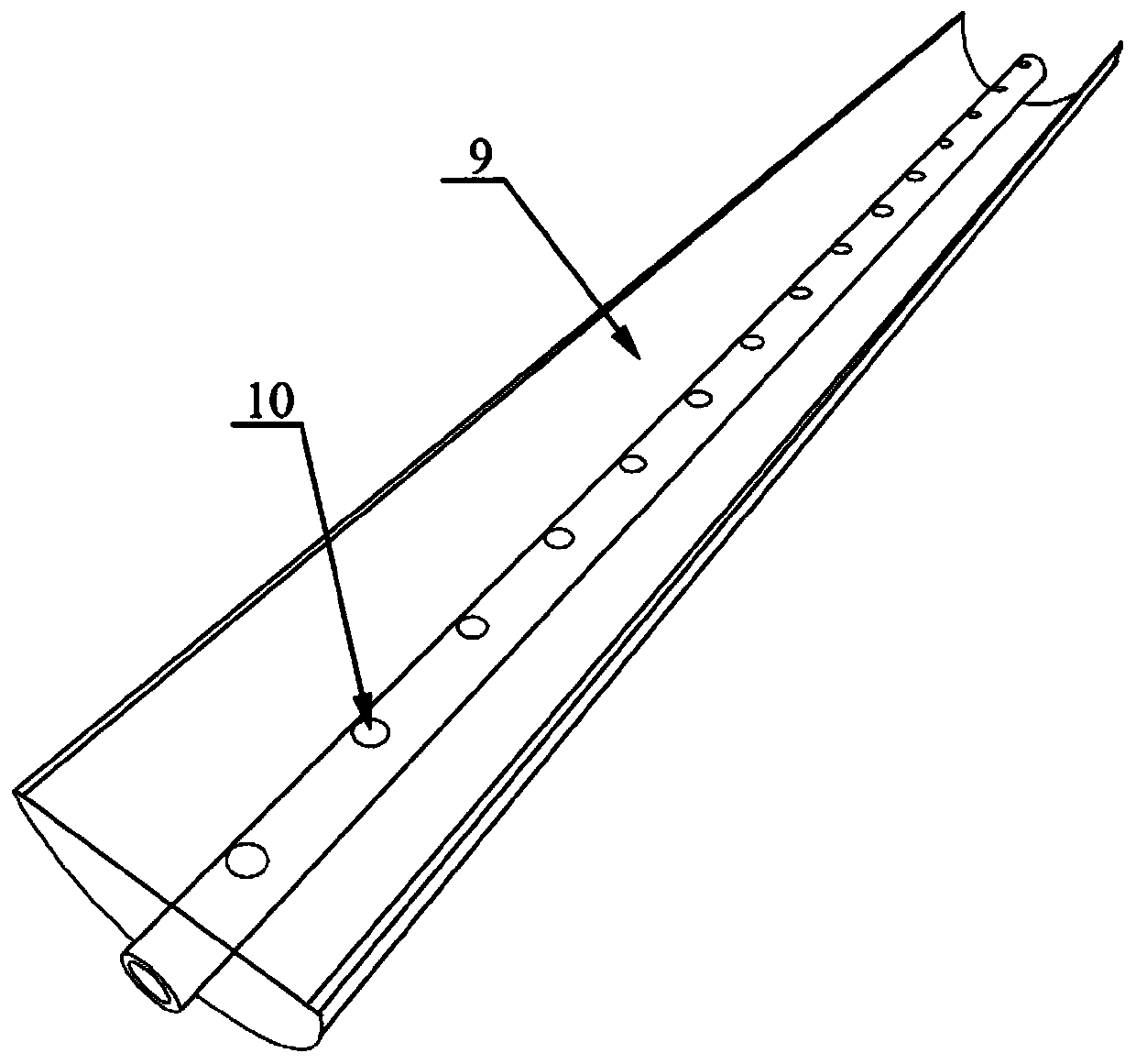

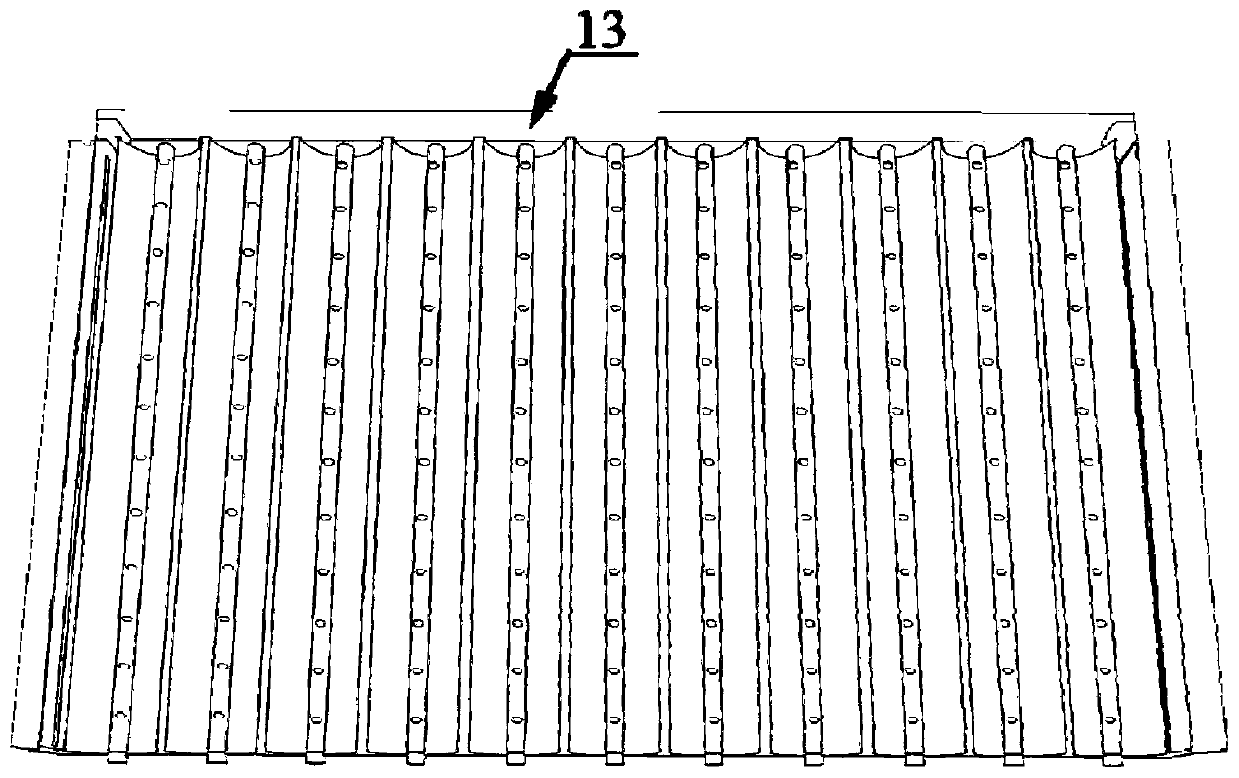

[0023] see Figure 1-5 As shown, a combined quick-freezing device based on a flat jet impingement evaporator includes: a bracket unit and a lower flat unit arranged in the bracket unit, a liftable upper flat unit, the upper flat unit, the lower flat unit It is respectively formed by docking a plurality of cargo plates 6 with a docking mechanism 7; the back of each cargo plate is connected to a flat jet impingement evaporator 4, and the outlet of the flat jet impingement evaporator is connected to the inlet of the compressor 1. The exhaust port is connected to the inlet of the condenser 2, the outlet of the condenser is connected to the inlet of the liquid separator 3, and each outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com