Explosive device capable of recycling dust and its application method

A dust and detection device technology, which is applied in blasting and other directions, can solve problems such as high cost of carbon dioxide blasting, environmental pollution by harmful substances, and large-space blasting preparations, and achieve the effects of avoiding the danger of artificial detonation, less environmental pollution, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

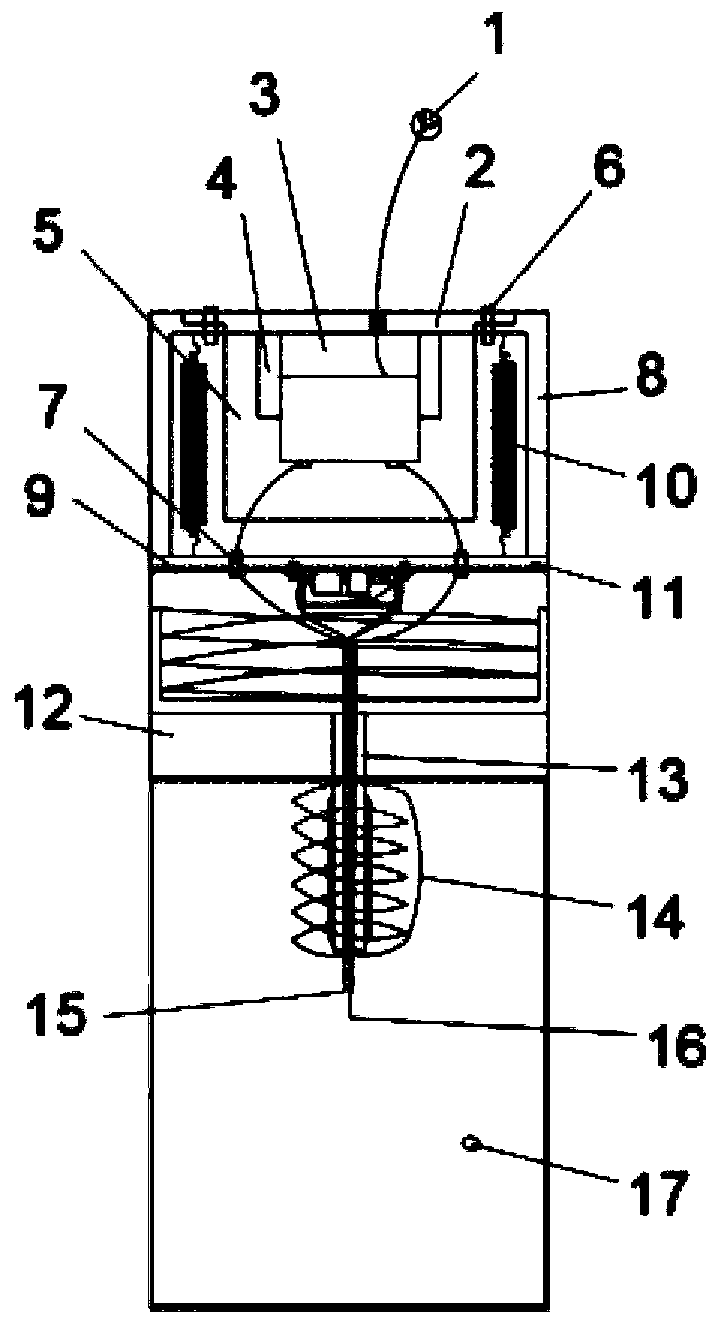

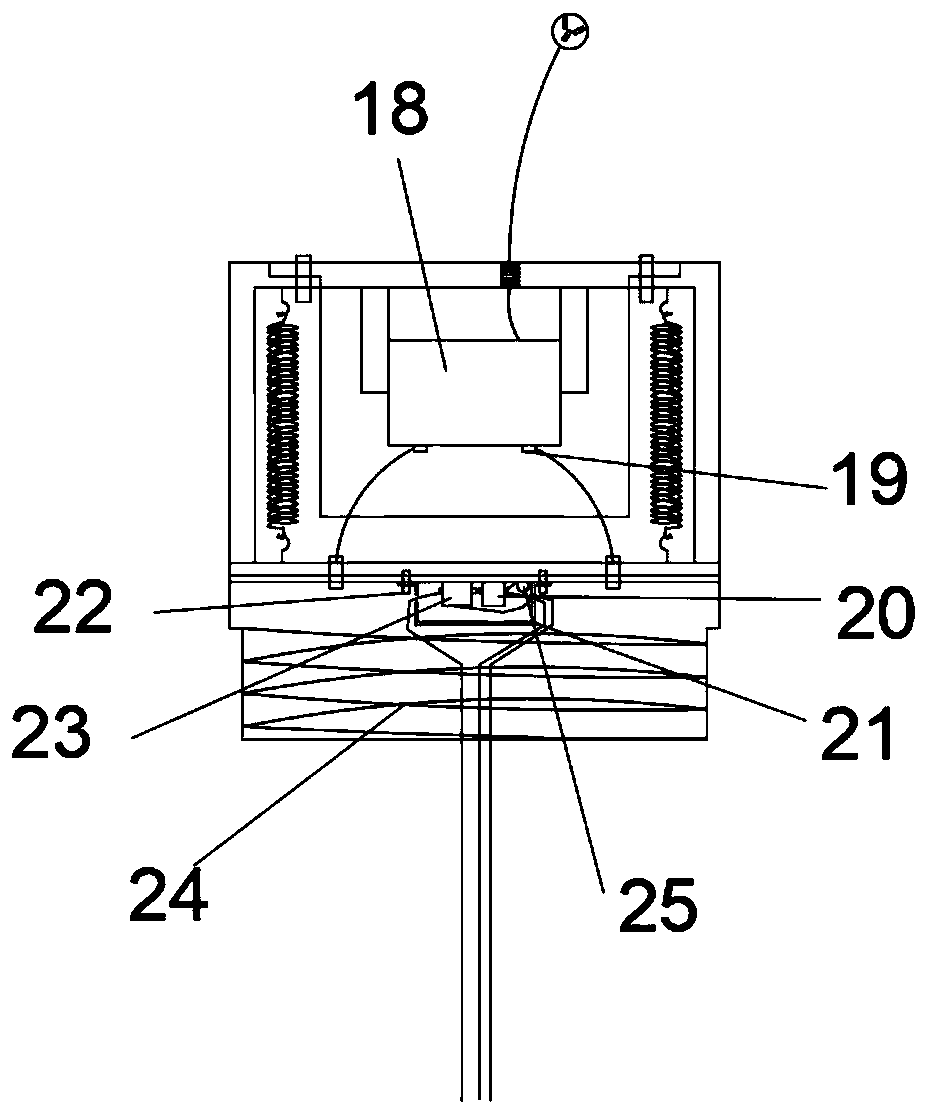

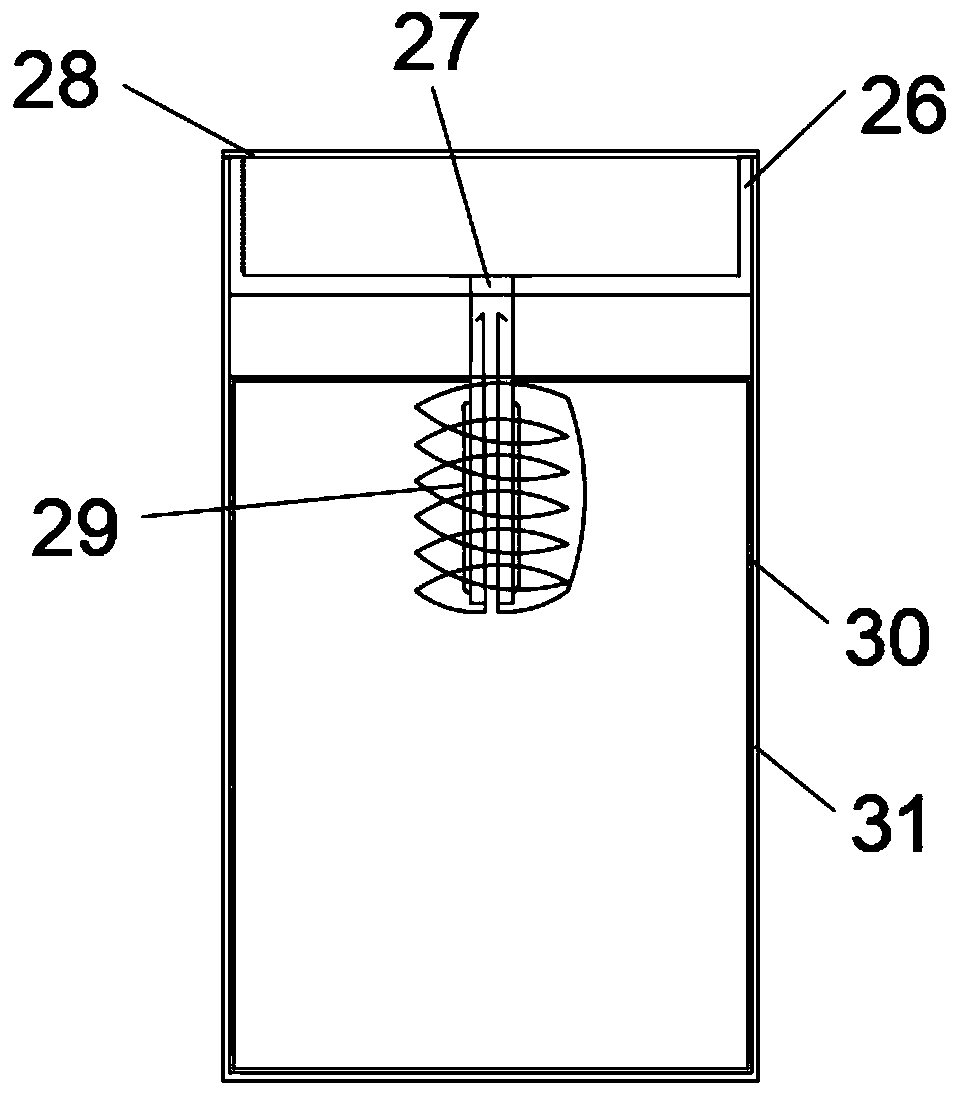

[0042] like figure 1 , figure 2 , image 3 As shown, the blasting device includes an upper recyclable device and a lower disposable device, specifically including a heating unit, a redox unit, an oxygen concentration detection unit, a temperature monitoring unit, an early warning unit, and a control ignition unit. The power supply and the coil are connected to play the role of heating; the oxidation-reduction unit uses the heat generated by the heating unit to accelerate the oxidation-reduction reaction of the oxidant; the oxygen concentration detection unit detects the oxygen generated by the oxidation-reduction action and judges whether the oxygen concentration meets the requirements of the dust explosion point Whether the temperature monitoring unit detects that the temperature reaches the detonation requirement; the early warning unit sends an early warning signal when the oxygen concentration and temperature are about to reach the detonation dust requirement point; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com