Servo system and its control method based on real-time motion control platform and fpga

A technology of motion control and servo system, applied in the direction of control system, vector control system, motor generator control, etc., can solve the problems of limited control performance, servo drive performance, inability to make full use of controller performance, and inability to achieve satisfactory control effects, etc. , to achieve the effect of shortening the control algorithm cycle, increasing flexibility, and meeting the requirements of high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The purpose of Embodiment 1 is to provide the first purpose of the present invention is to provide a servo system based on a real-time motion control platform and FPGA.

[0054] In order to achieve the above object, the present invention adopts the following technical scheme:

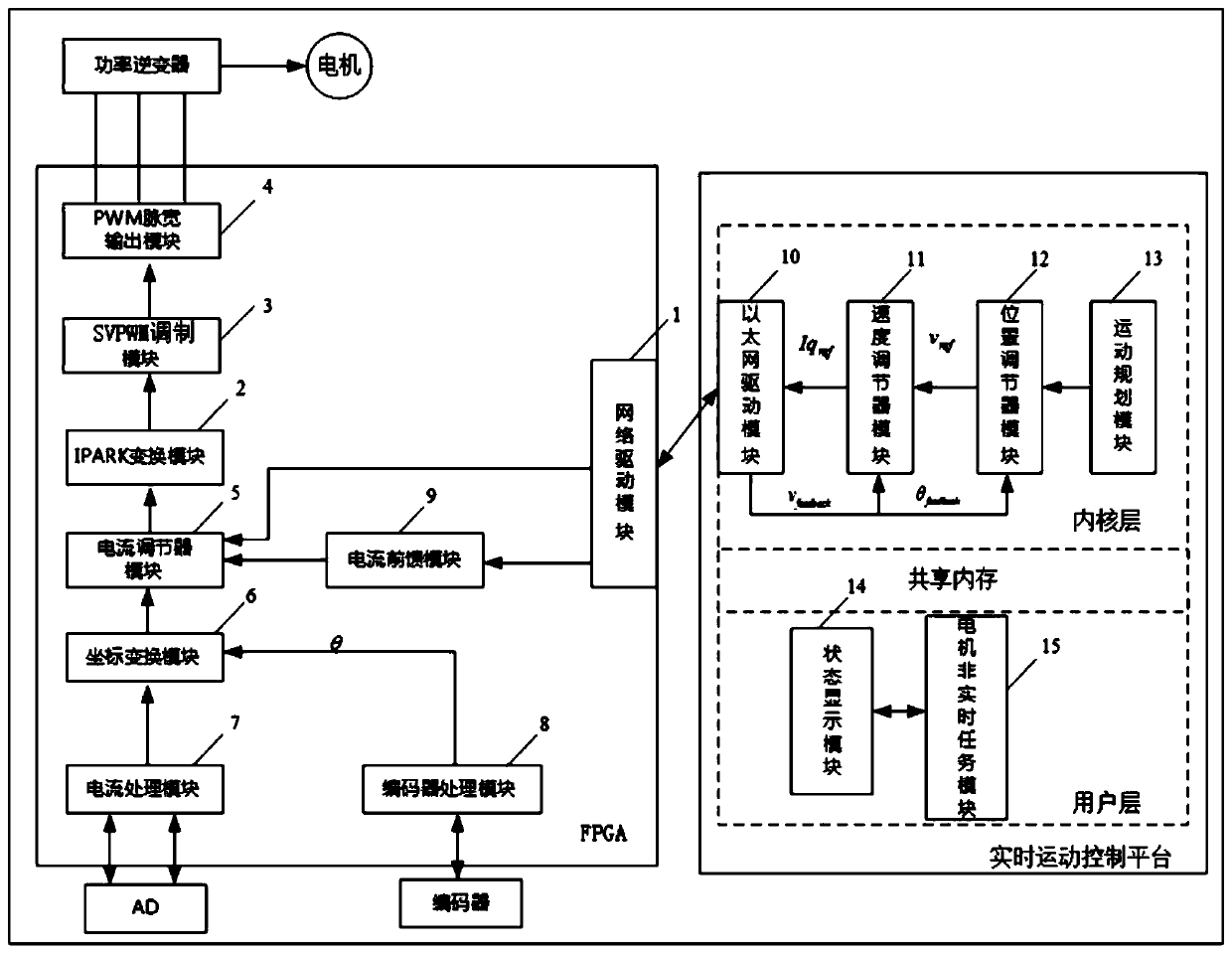

[0055] like figure 1 as shown,

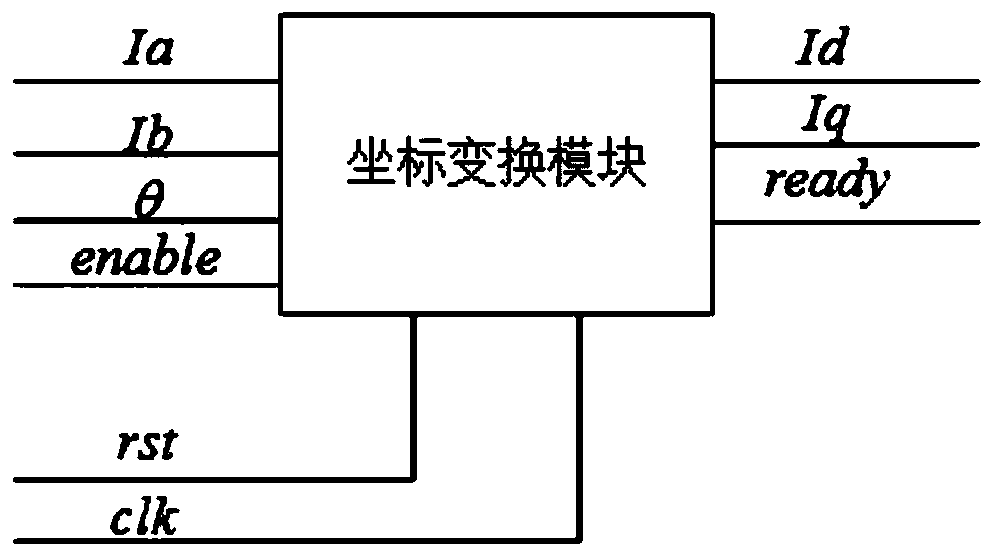

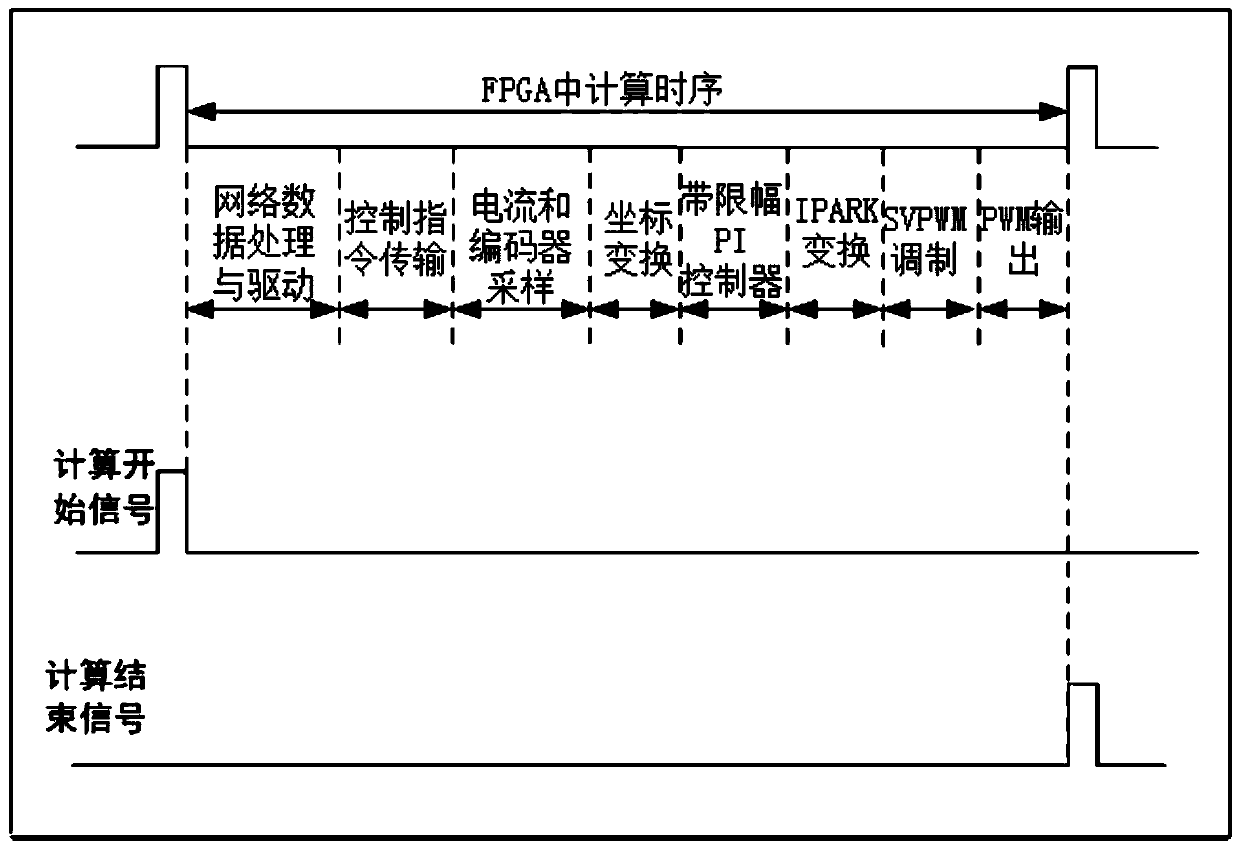

[0056] A servo system based on a real-time motion control platform and an FPGA, the system mainly includes two parts: a real-time motion control platform and an FPGA connected by sequential communication; the real-time motion control platform is configured to run a motion planning algorithm to obtain given position information, The output is transmitted to the industrial Ethernet network through the position regulator and the speed regulator respectively, and the data interaction with the FPGA is performed; the FPGA is configured to receive the current reference vector signal transmitted by the industrial Ethernet, and through the pure hardware logic circuit The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com