Production equipment and technology of egg round flat cakes

A technology of production equipment and production process, which is applied in the field of production equipment and technology of egg round cakes, can solve the problems of affecting the appearance of egg round cakes, not suitable for egg round cakes, and easy cracking of products, so as to achieve beautiful appearance and improve the degree of automatic production , beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

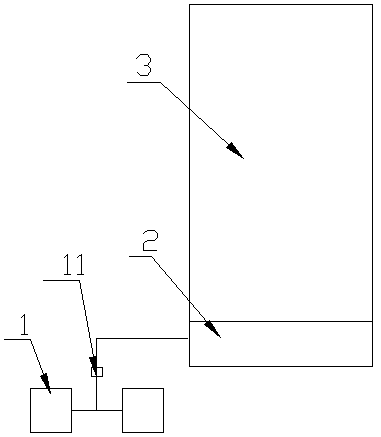

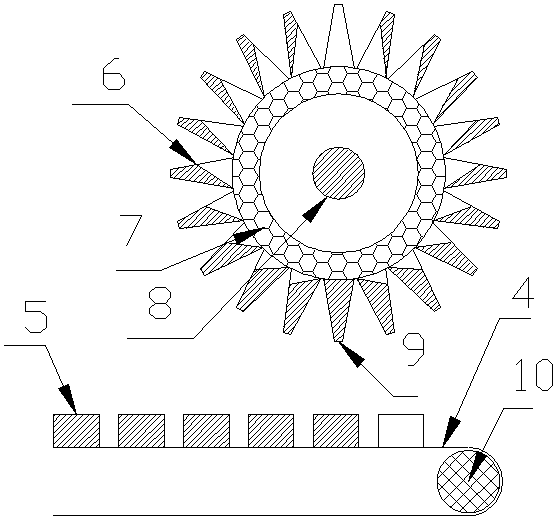

[0057] A kind of production equipment and technology of egg round cake, comprise premixing device 1, feeding device 2, tunnel furnace 3 and conveying device 4, described premixing device 1 is connected with feeding device 2 by pipeline, described feeding device 2 is connected with the tunnel furnace 3 through the conveying device 4, and the mold 5 is set on the conveying device 4. The premixing device 1 includes a storage tank and an agitator, the agitator is located in the storage tank, a feed inlet and a discharge port are arranged on the storage tank, and the discharge port passes through a pipeline It is connected with the feeding device, and a feeding pump 11 is arranged on the pipeline. The feeding device 2 includes a discharger 6, a controller and a rotating mechanism, the rotating mechanism includes a motor and a rotating shaft 7, the rotating shaft 7 is connected with the motor, and the discharging device 6 is installed on the rotating shaft 7 On, the discharger 7 is...

Embodiment 2

[0074] Embodiment 2 is different from Embodiment 1 in that the production process of the described egg round cake includes premixing, feeding and baking processes, and the described premixing process includes the following steps:

[0075] (1) Premixing of raw materials, the raw materials include butter, sugar, edible oil, flour, food additives and water, put all the butter, 1% of edible oil and 1% of water into the storage tank, stirrer Rotate at 120 rpm, stir for 10 min;

[0076] (2) Stir, add all the remaining raw materials in step 1 except the flour into the storage tank, stir at a speed of 100 rpm, and stir for 10 minutes;

[0077] (3) Add the flour into the storage tank, stir with the agitator at 80 rpm for 10 minutes;

[0078] (4) Let stand for 3 minutes.

[0079] Described feeding process comprises:

[0080] The rotating speed of the rotating mechanism is 40 revolutions / min.

[0081] Described baking process comprises:

[0082] (1) For the first stage of baking, th...

Embodiment 3

[0086] The difference between embodiment 3 and embodiment 1 is that the production process of the described egg round cake includes premixing, feeding, and baking processes, and the described premixing process includes the following steps:

[0087] (1) Raw materials are premixed. The raw materials include butter, sugar, edible oil, flour, food additives and water. Put all the butter, 10% of edible oil and 20% of water into the storage tank, and the mixer The speed is 60 rpm, stirring for 20 minutes;

[0088] (2) Stir, add all the remaining raw materials in step 1 except the flour into the storage tank, stir at a speed of 40 rpm, and stir for 25 minutes;

[0089] (3) Add the flour into the storage tank, stir with the agitator at 20 rpm for 25 minutes;

[0090] (4) Let stand for 5 minutes.

[0091] Described feeding process comprises:

[0092] The rotational speed of the rotating mechanism is 20 revolutions / min.

[0093] Described baking process comprises:

[0094] (1) For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com