Low-sugar type DHA algal oil gel candy and preparation method thereof

An oil-gel candy and sugar-type technology, applied in confectionary, confectionary industry, food science, etc., can solve the problems of short shelf life, deterioration, easy oxidation, etc., and achieve extended shelf life, slightly sweet taste, and low cariogenicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of above-mentioned low-sugar type DHA algae oil gel candy, comprises the steps:

[0054](1) Preparation of core material (mixed oil): DHA algae oil, linseed oil and walnut oil are evenly mixed according to the formula, left to defoam, and set aside;

[0055] (2) Preparation of premix 1 (sugar-boiled wall material): weigh glycerin, sorbitol liquid, maltitol liquid and trehalose according to the formula, mix them at room temperature, and set aside;

[0056] (3) Preparation of wall materials: Add water into the glue tank according to the formula, preheat to 75-85°C, add gelatin and the premix 1 prepared in step (2), keep warm and stir until the gelatin is completely After dissolving, turn on the vacuum pump to extract the air bubbles in the glue solution for about 30-50 minutes; put the glue solution in an insulated bucket after passing through a 100-mesh sieve, keep it warm at 55-65°C, and let it stand overnight for later use.

[0057] (4) Pill pre...

Embodiment 1

[0061] Embodiment 1 A kind of low-sugar type DHA algae oil gel candy

[0062] All raw materials are obtained from qualified products that meet the corresponding national standards / industry standards and national regulations after strict screening;

[0063] Accurately weigh 70g of DHA algae oil, 18g of linseed oil, and 12g of walnut oil, respectively, for preparing core materials;

[0064] Accurately weigh 39.6g of water, 37.9g of gelatin, 16.5g of glycerin, 2.7g of sorbitol solution, 2.5g of maltitol solution, and 0.8g of trehalose to prepare wall materials.

[0065] Its preparation method comprises the following steps:

[0066] (1) Preparation of core material (mixed oil): DHA algae oil, linseed oil and walnut oil are evenly mixed according to the formula, left to defoam, and set aside;

[0067] (2) Preparation of premix 1 (sugar-boiled wall material): weigh glycerin, sorbitol liquid, maltitol liquid and trehalose according to the formula, mix them at room temperature, an...

Embodiment 2

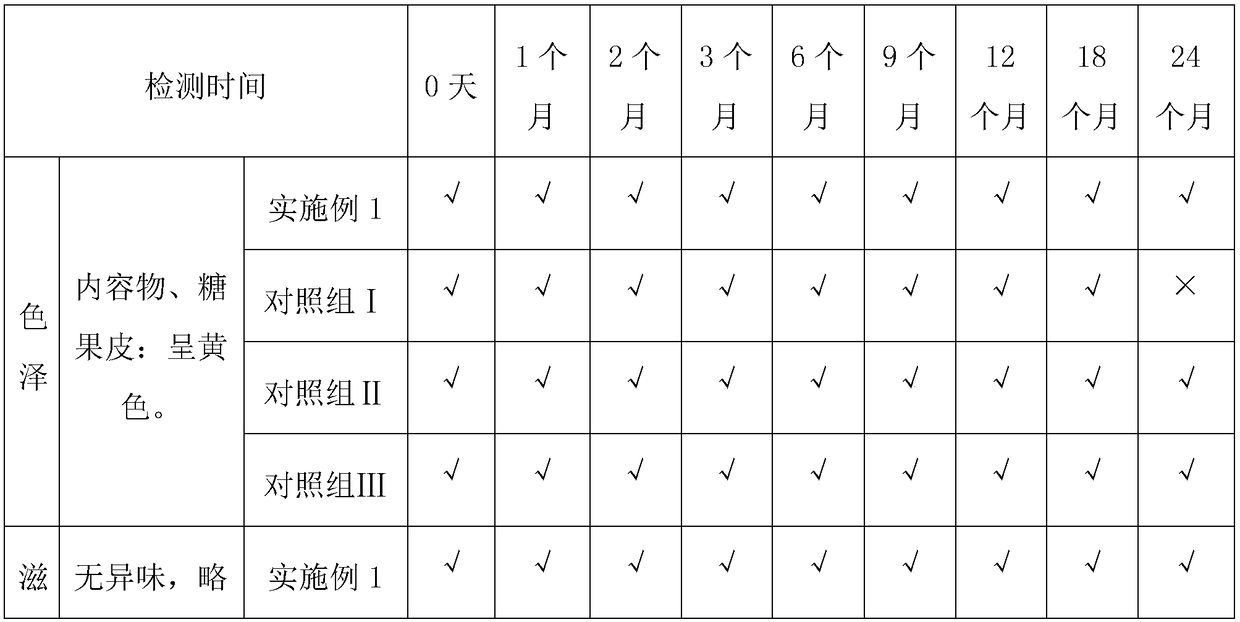

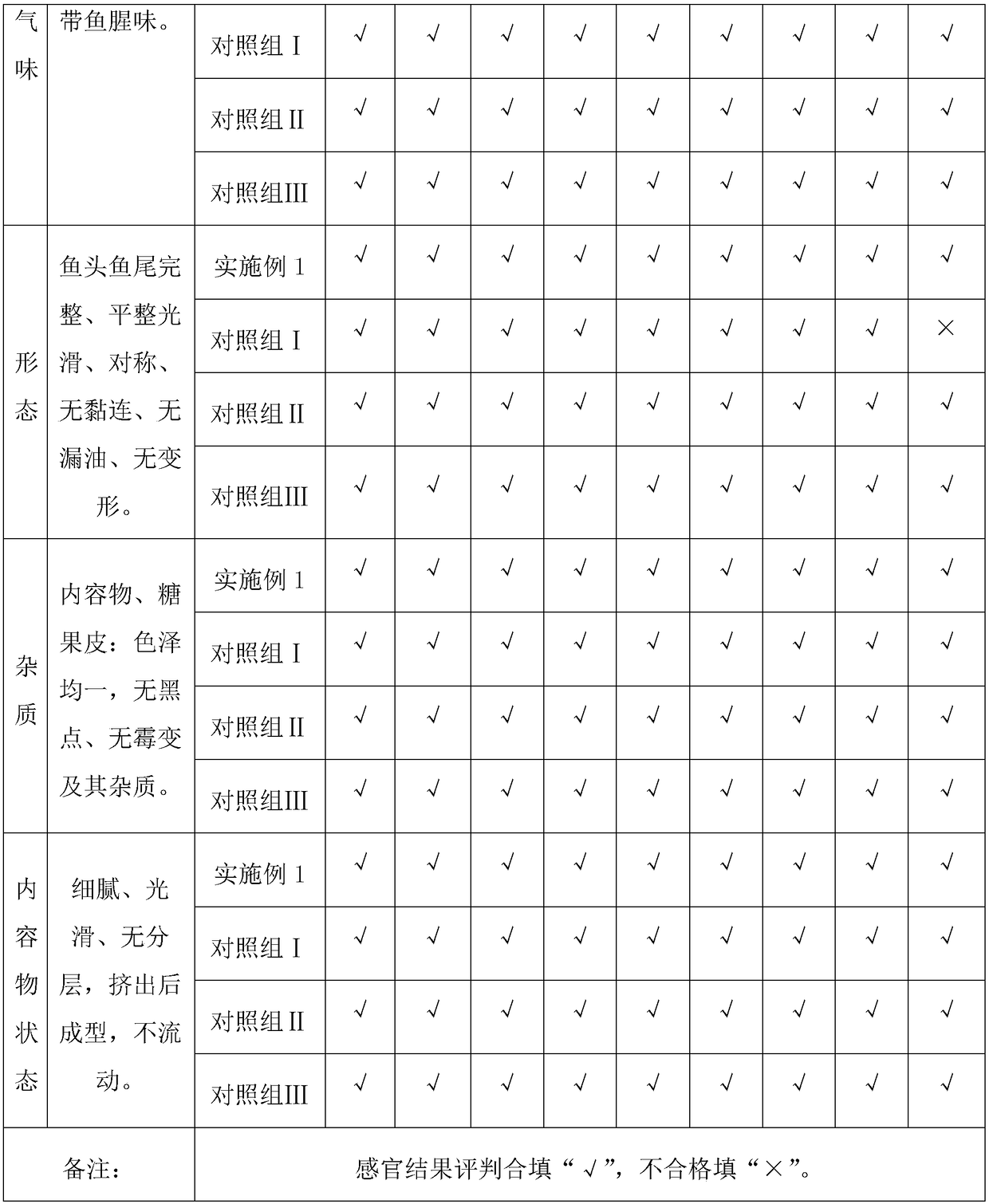

[0073] Embodiment 2 Stability experiment

[0074] The stability of algae oil is judged by sensory and oil peroxidation value (POV) ≤ 0.25g / 100g (ie ≤ 19.7meq / kg). Determine the shelf life of algae oil at room temperature by measuring the product stability test for 24 months at room temperature.

[0075] Under laboratory room temperature conditions, the formula group and the control group were taken out at 0 days, 1 month, 2 months, 3 months, 6 months, 9 months, 12 months, 18 months and 24 months respectively. Ⅰ. Control group II and control group III have 9 capsules each, of which 3 capsules are used for sensory test, and the other 6 capsules are used for oil POV measurement.

[0076] Control group Ⅰ: Accurately weigh 70g of DHA algae oil, 18g of linseed oil, and 12g of walnut oil to make core materials; accurately weigh 34g of water, 34g of gelatin, 26g of glycerin, 2.7g of sorbitol solution, and 2.5g of maltitol solution , Trehalose 0.8g prepared as wall material.

[0077...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com