Photocuring 3D printer and printing method thereof

A 3D printer and light curing technology, applied in manufacturing tools, processing data acquisition/processing, additive manufacturing, etc., can solve the large size requirements of light curing 3D printers, the high cost of light curing 3D printers, and the single LCD liquid crystal display. size and other issues, to achieve the effect of being conducive to storage and transportation, high contrast, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

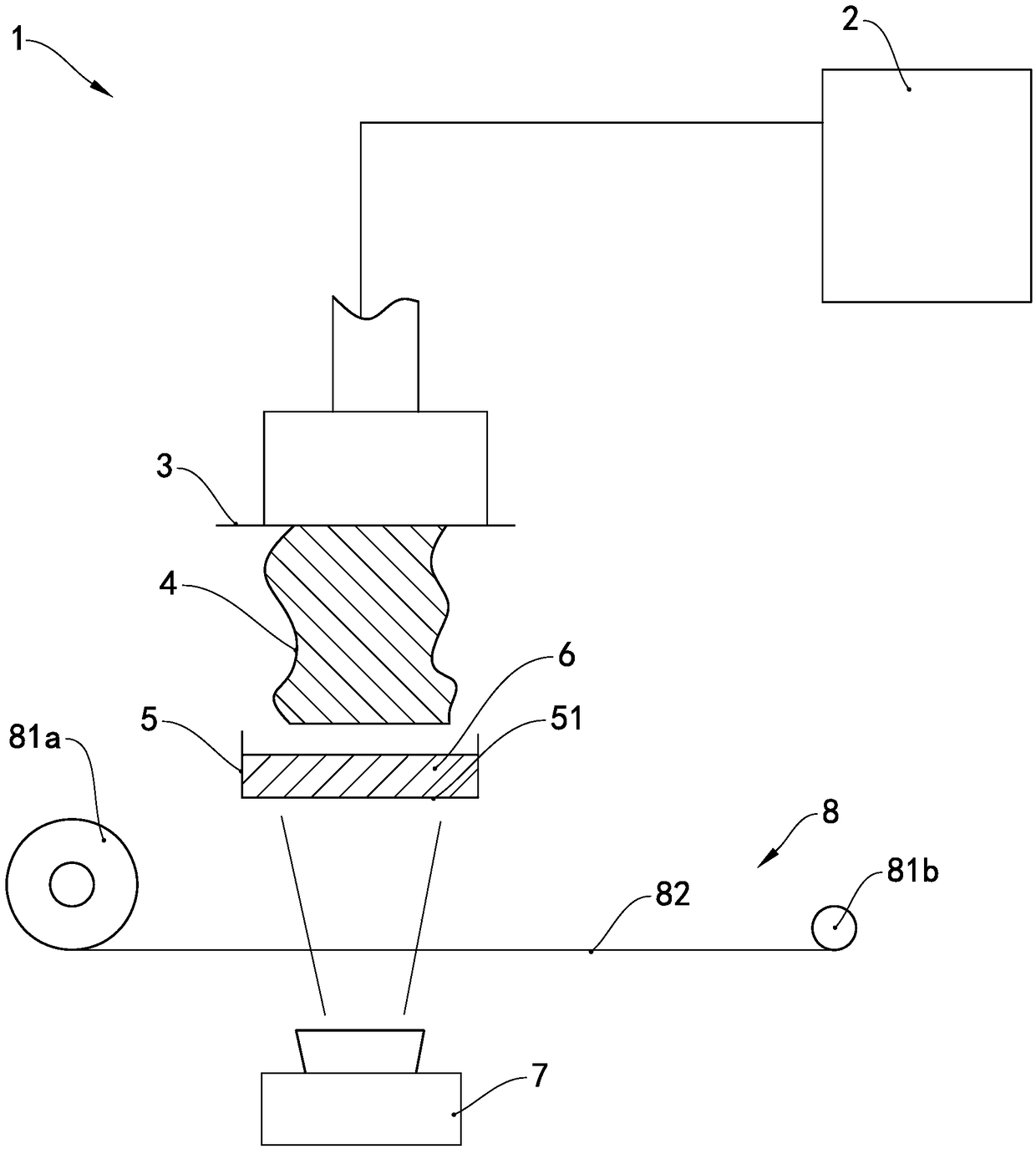

[0031] see Figure 1 to Figure 3 The light-curing three-dimensional printer 1 includes a forming tank 5 for carrying a molding material 6, a printing platform 3 arranged above the forming tank 5, a control device 2 for controlling the vertical movement of the printing platform 3, and a light-curing device located below the forming tank 5 , the light curing device is provided with a light processing device 7 and an organic light-emitting diode (Organic Light-Emitting Diode, OLED for short) display screen 8, and the OLED display screen 8 is located between the forming groove 5 and the light processing device 7. Wherein, the printing platform 3 is made of transparent material, and the forming groove 5 is also made of transparent material. The OLED display screen 8 of this embodiment is a display screen made of organic electroluminescent diodes, equipped with self-luminous organic electroluminescent diodes, has high contrast, thin thickness, wide viewing angle, fast response speed...

no. 2 example

[0041] As an explanation of the second embodiment of the photo-curable three-dimensional printer of the present invention, only the differences from the first embodiment of the photo-curable three-dimensional printer will be described below.

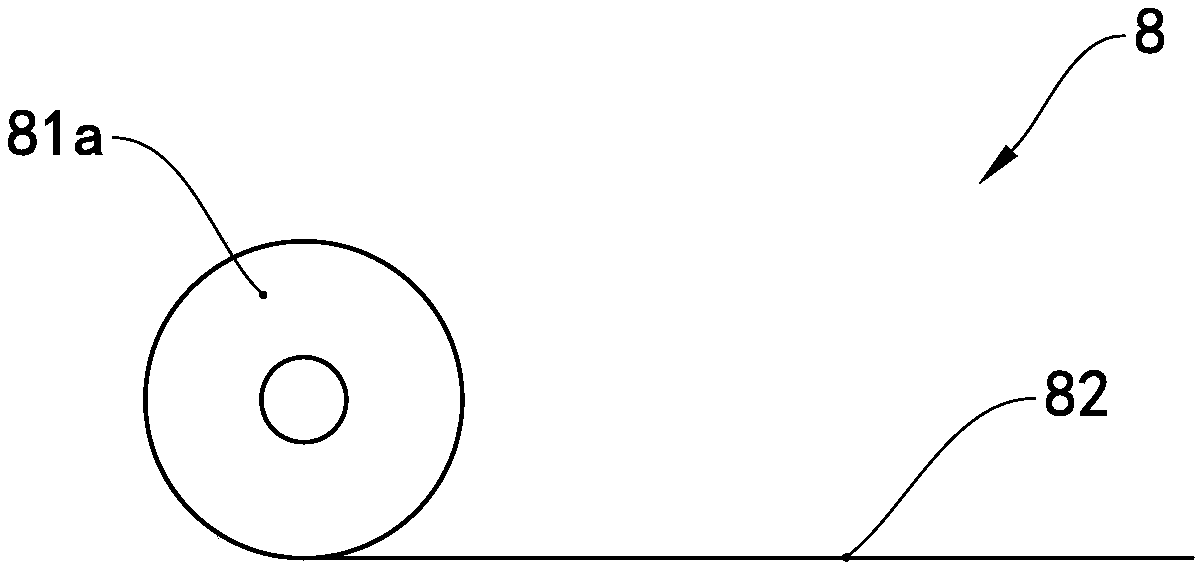

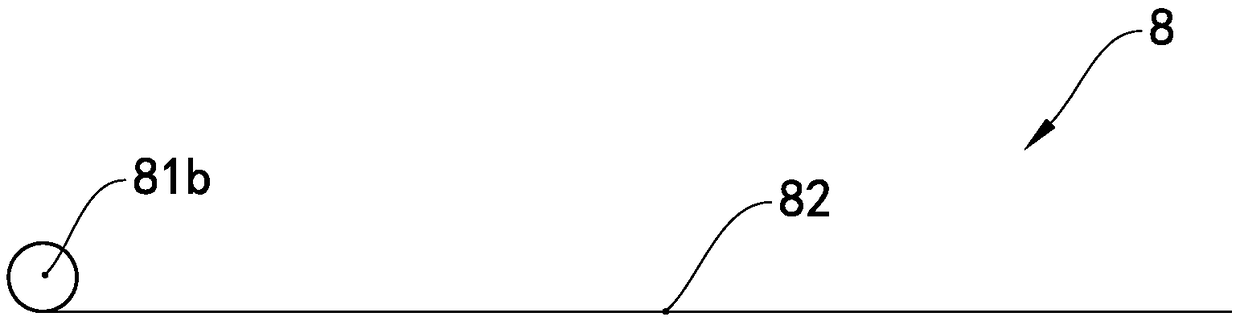

[0042] The OLED display screen has an extension part and a projection part, the extension part has an open state and a folded state, and the projection part is connected to the extension part. When the extension part is in an open state, the area of the projection part becomes larger. When the extension part is in the folded state, the area of the projection part becomes smaller.

[0043] The OLED display screen of the light-curing 3D printer in this embodiment can be folded. When a large object needs to be printed, the extension part of the OLED display screen in the folded state can be unfolded to realize large-format printing and realize the 3D printing of large objects by a small printer. Print. OLED displays make 3D printing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com