Stable tourmaline slurry and preparation method thereof

A technology of tourmaline and slurry, which is applied in the field of science and technology and environmental protection, can solve the problems of inconvenient use, high density of tourmaline, and low internal efficiency, and achieve the effects of convenient use, increased content, and increased use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

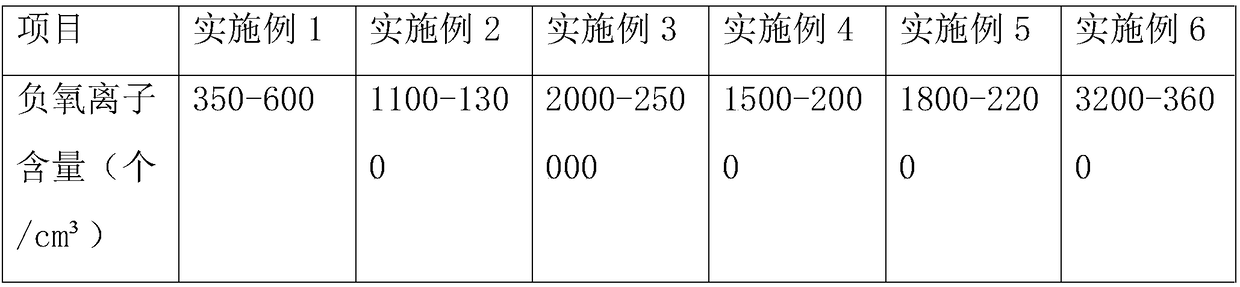

Embodiment 1

[0024] A kind of preparation method of stable tourmaline slurry is:

[0025] Put the high-purity cotton purchased in the market into a beaker, then add an appropriate amount of hydrogen peroxide with a concentration of 2-5%, soak for 1-2 hours, and then drain the water in the cotton to obtain relatively dry cotton , take by weight 10-20 parts of cotton and put it into the reaction kettle, then add 120 parts of cuproammonia solution, the concentration of the cuproammonia solution is controlled at 10%, open the agitator for reaction, and its stirring speed is controlled at 500rpm , after the cotton is completely dissolved, stop stirring, then take it out for later use, add 300 parts of sulfuric acid solution with a concentration of 3mol / L in the reaction kettle, add the spare solution into the constant pressure burette, turn on the stirrer, and control the stirring speed at 600rpm, then open the constant pressure burette, the dropping point speed is controlled at 1-2 drops / secon...

Embodiment 2

[0028] A kind of preparation method of stable tourmaline slurry is:

[0029] Put the high-purity cotton purchased in the market into a beaker, then add an appropriate amount of hydrogen peroxide, the concentration of which is 5%, soak for 1-2 hours, and then drain the water in the cotton to obtain relatively dry cotton, which is called Take 10 parts of cotton by mass and put it into the reaction kettle, then add 100 parts of cuproammonia solution, the concentration of cuproammonia solution is controlled at 10%, and the stirrer is turned on for reaction, and the stirring speed is controlled at 500-600rpm. After the cotton is completely dissolved, stop stirring, then take it out for use, add 200-300 parts of sulfuric acid solution with a concentration of 3mol / L in the reaction kettle, add the spare solution into the constant pressure burette, turn on the stirrer, and control the stirring speed at 400-600rpm, then open the constant pressure burette, control the dropping point spe...

Embodiment 3

[0032] A kind of preparation method of stable tourmaline slurry is:

[0033] Put the high-purity cotton purchased in the market into a beaker, then add an appropriate amount of hydrogen peroxide, the concentration of which is 5%, soak for 1-2 hours, and then drain the water in the cotton to obtain relatively dry cotton, which is called Take 20 parts of cotton by mass and put it into the reactor, then add 120 parts of cuproammonia solution, the concentration of cuproammonia solution is controlled at 10%, open the agitator to react, its stirring speed is controlled at 600rpm, until the cotton is completely After dissolving, stop stirring, then take it out for later use, add 300 parts of sulfuric acid solution with a concentration of 3mol / L in the reaction kettle, add the spare solution in the constant pressure burette, turn on the stirrer, control the stirring speed at 500rpm, and then turn on the Constant pressure burette, the dropping point speed is controlled at 1-2 drops / sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com