Split sandwich heat-insulation wall combined type connecting piece

A technology for thermal insulation walls and connectors, applied in thermal insulation, walls, building components, etc., can solve the problems of increased construction difficulty, inconvenient installation and disassembly, and unsuitable for large-scale laying and installation of building walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

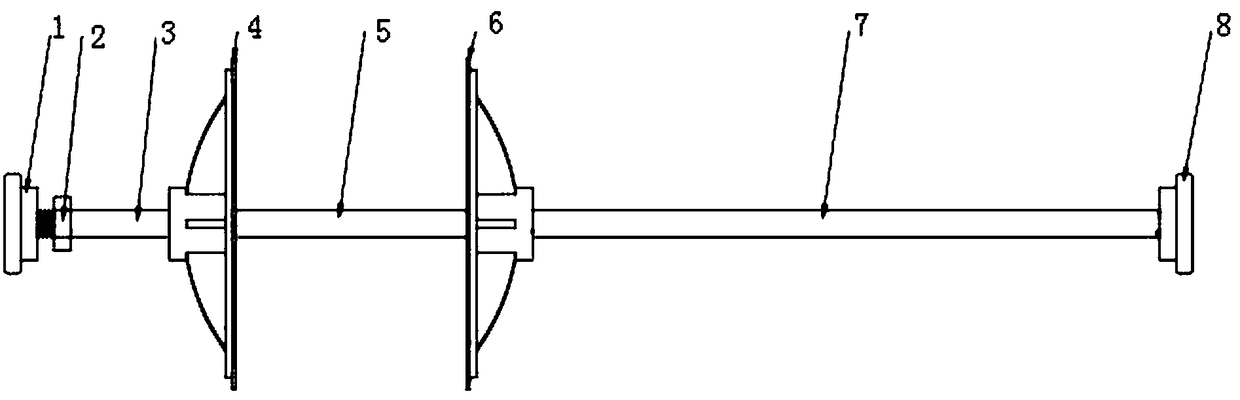

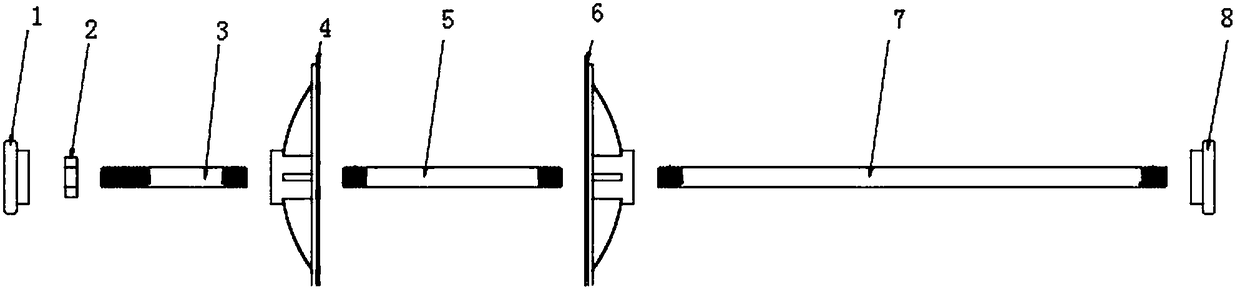

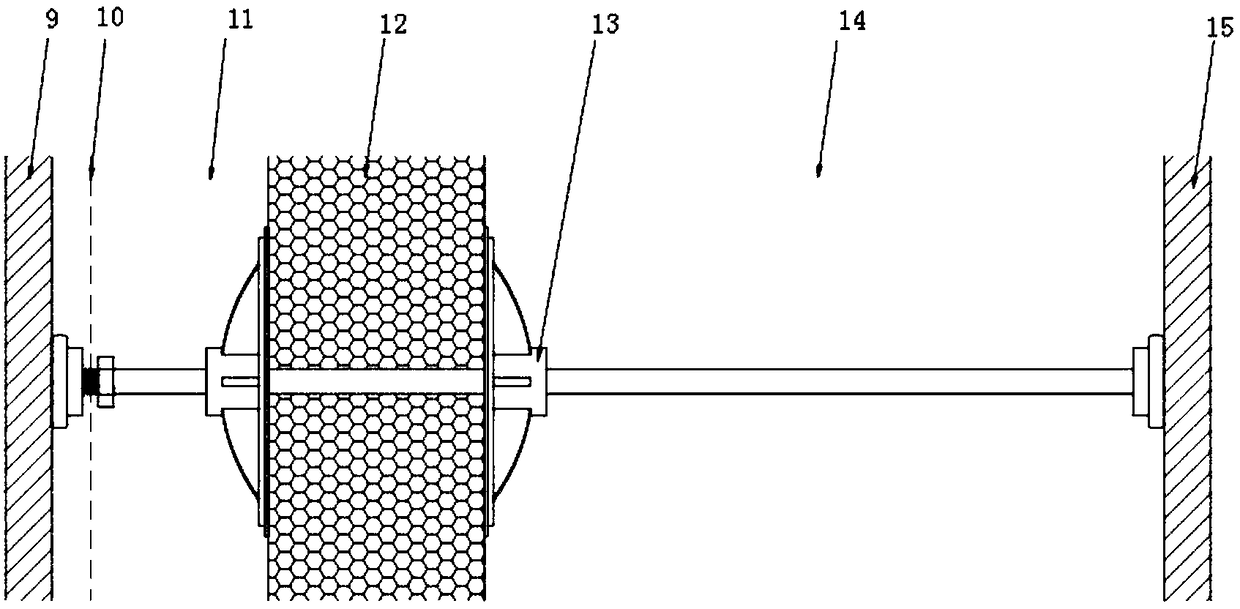

[0023] Combined with the manual figure 1 , figure 2 and image 3 As shown, a split sandwich insulation wall combined connector includes inner and outer cylindrical ends, an inner baffle plate 2, a first steel bar connecting rod 3, an outer clamping disc 4, a second connecting rod 5, an inner clamping The disc 6 and the third connecting rod 7 are composed of; the clamping disc is set as a semicircular pot cover shape, and the inner threaded through hole 13 is installed on the centerline direction of the circular convex surface of the clamping disc, and the connecting piece is installed Connect sequentially from left to right:

[0024] A steel wire mesh 10 is set between the outer cylindrical end 1 and the inner baffle plate 2, and is connected to the threaded rod at the left end of the first connecting rod 3, and the threaded rod at the right end of the first connecting rod 3 is connected to the threaded rod at the right end of the first connecting rod 3. 13 in the inner th...

Embodiment 2

[0026] The inner and outer clamping discs are in the shape of an outer circular terrace, and the connecting rod is set in three sections.

Embodiment 3

[0028] Based on the basis of Examples 1 and 2, the one-stage connecting rod is used for installation of the interior wall insulation, which does not need to hang the wall skin, and the installation is beautiful and fast. Reduce the area of the inner wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com