Method and system for classifying and detecting oxide scales in boiler pipes

A technology for scale and boiler application in the processing of detection response signals and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids. Pipeline hazards and other issues to achieve the effect of avoiding the danger of pipe explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

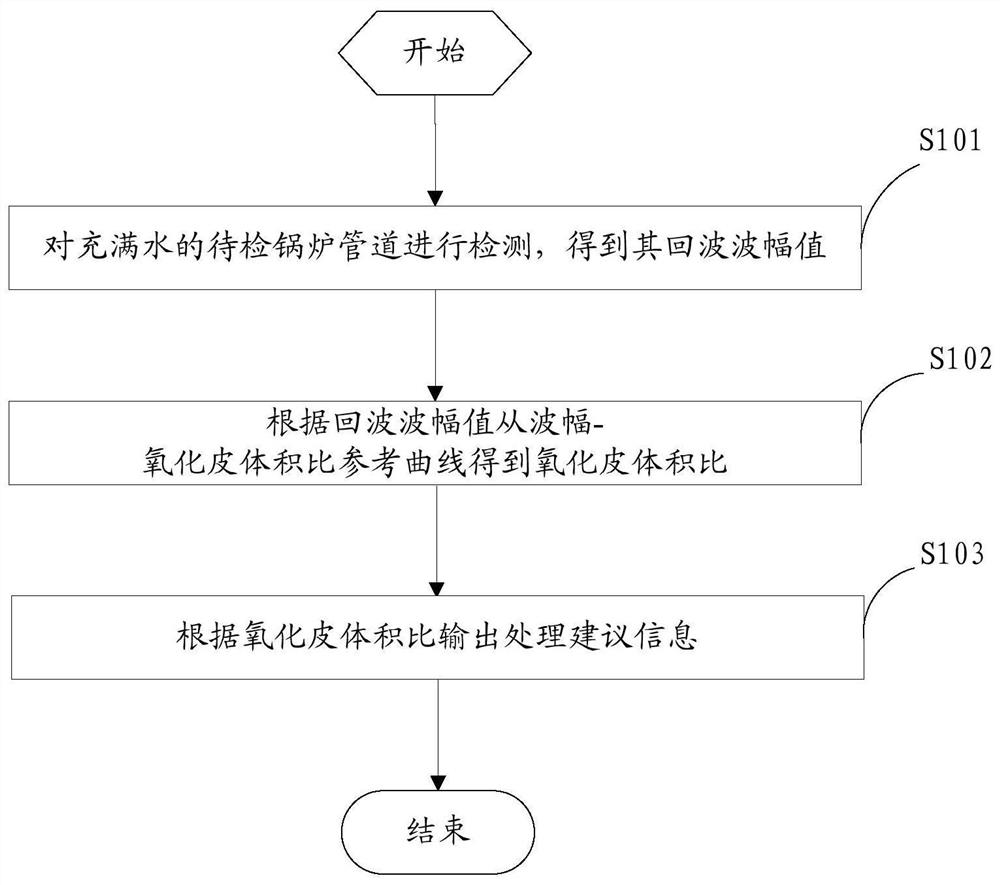

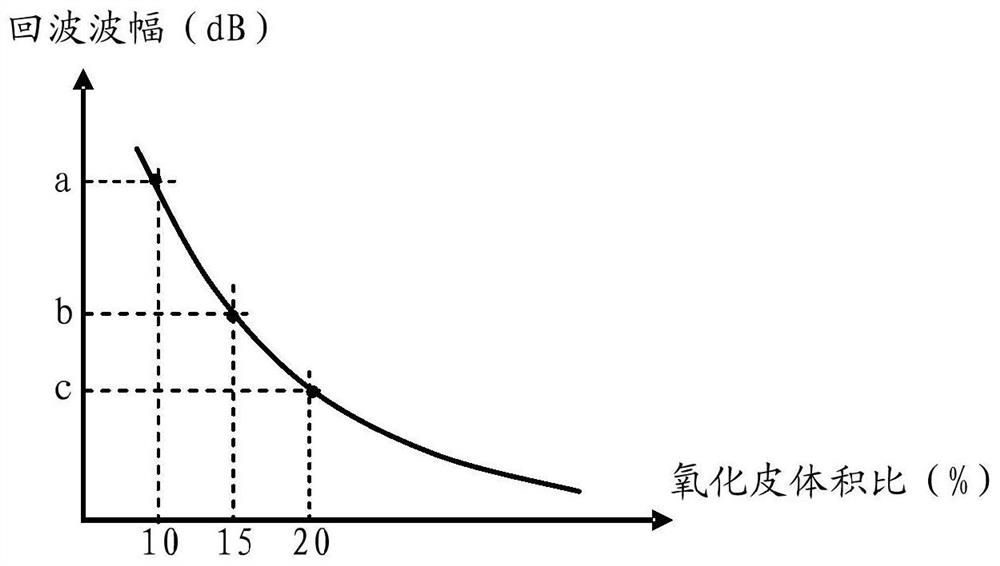

[0048] figure 1 A step-by-step flow chart of a method for graded detection of scale in boiler pipes provided in the embodiment of the present application.

[0049] like figure 1 As shown, the graded detection method of this embodiment is used to detect the scale generated in the boiler pipes after long-term operation, and output the graded detection results, especially for the detection of steam side pipes of power plant boilers. The graded detection method Specifically include the following steps:

[0050] S101: Detect the water-filled boiler pipe to be inspected to obtain the echo amplitude thereof.

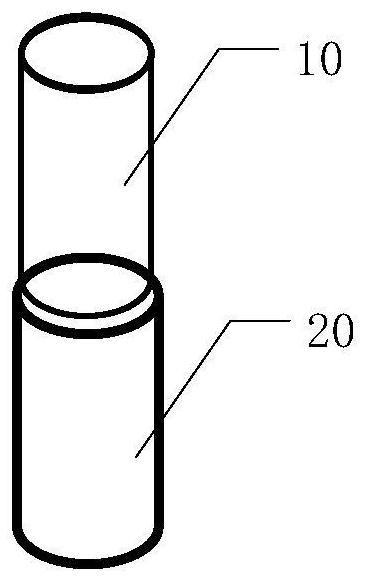

[0051] The detection is to use the corresponding ultrasonic detection equipment to detect the boiler pipe to be inspected, and obtain the echo wave amplitude of the ultrasonic echo generated by the ultrasonic wave in the boiler pipe to be inspected. Specifically, two longitudinal wave straight probes are selected, one as the transmitting probe and the other as the receiving ...

Embodiment 2

[0088] Figure 4 A structural block diagram of a system for grading and detecting oxide scales in boiler pipes provided in an embodiment of the present application.

[0089] like Figure 4 As shown, the graded detection system of this embodiment is used to detect the scale generated in the boiler pipes after long-term operation, and output the graded detection results, especially for the detection of steam side pipes of power plant boilers. The graded detection system It specifically includes an ultrasonic detection module 30 , a table lookup calculation module 40 and an information output module 50 .

[0090] The ultrasonic detection module is used to detect the water-filled boiler pipe to be inspected to obtain the echo wave amplitude.

[0091] The detection is to use the corresponding ultrasonic detection equipment to detect the boiler pipe to be inspected, and obtain the echo wave amplitude of the ultrasonic echo generated by the ultrasonic wave in the boiler pipe to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com