Digital power supply circuit based on MEMS sensor

A digital power supply and sensor technology, applied in electronic circuit testing, electrical measuring instrument components, instruments, etc., can solve problems such as poor stability, inability to detect multiple MEMS sensors at the same time, and high power consumption of current sources, so as to improve stability , Smooth loop oscillation charging and discharging process, low power consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

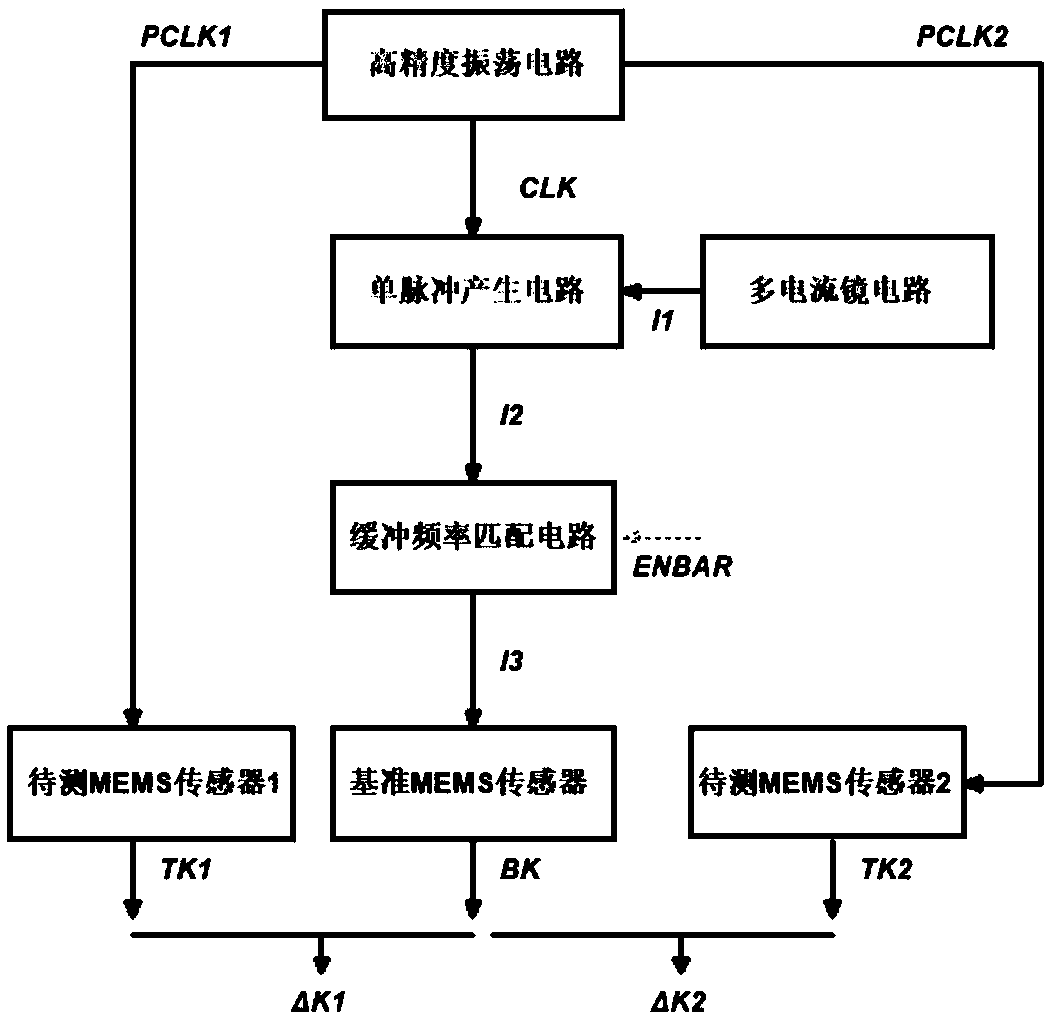

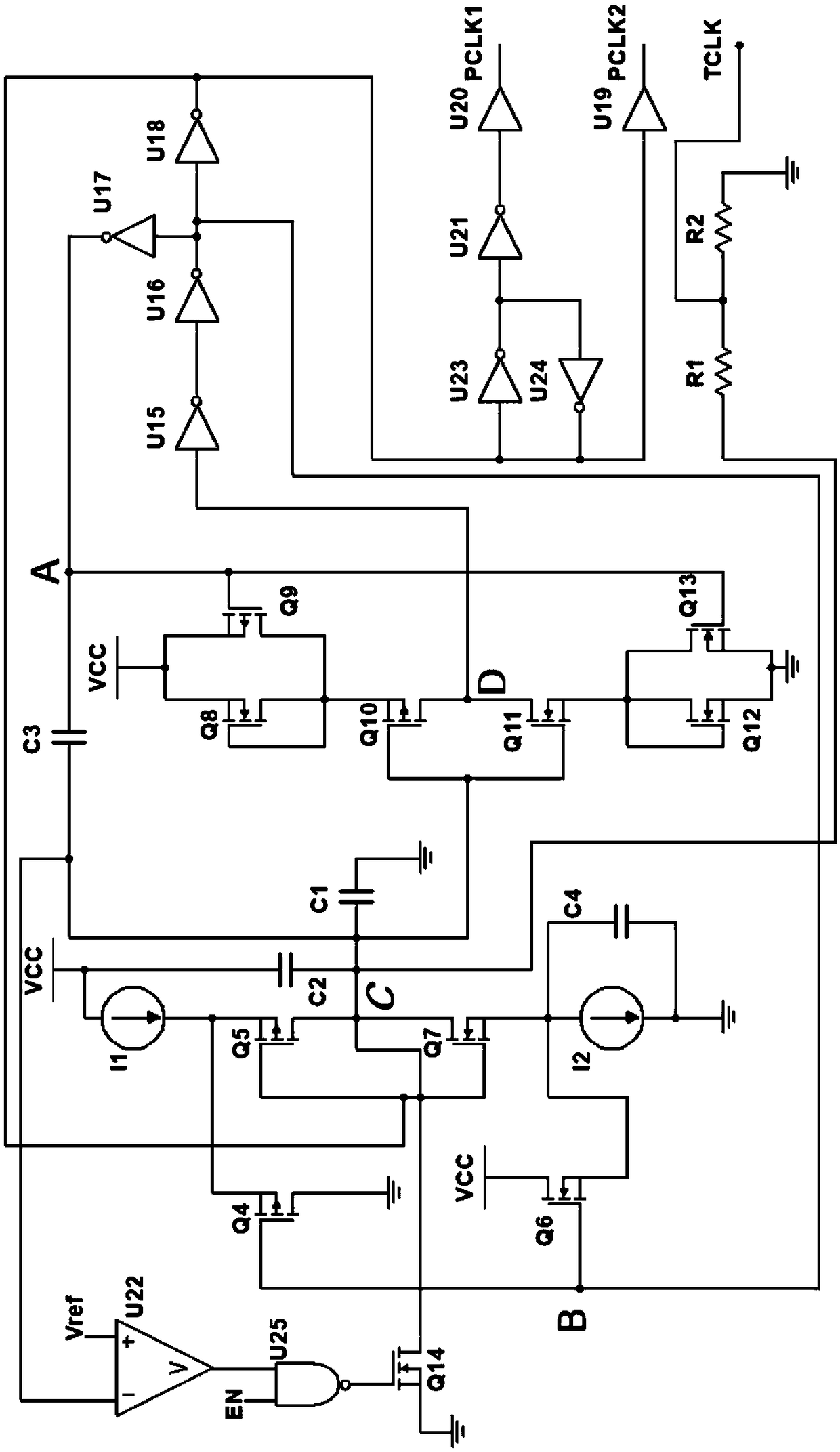

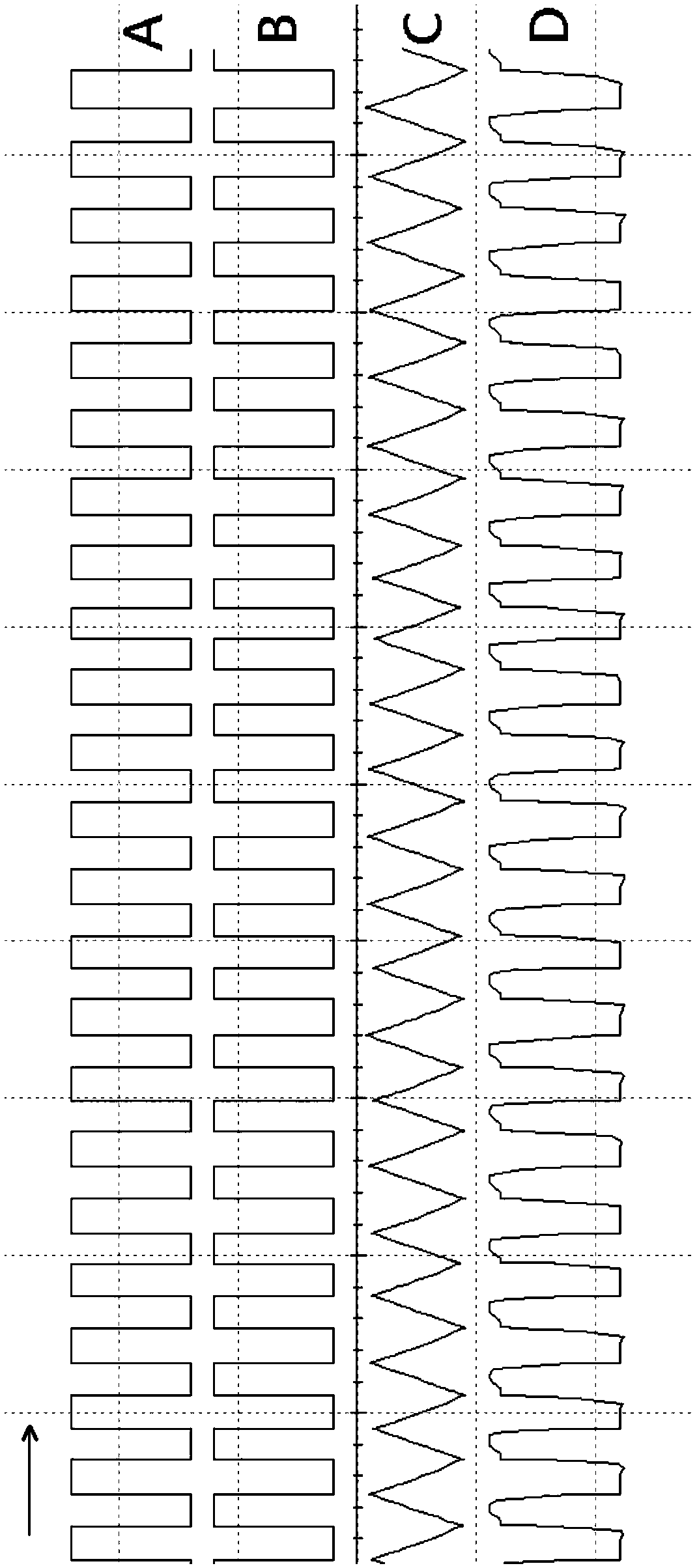

[0067] High-precision oscillating circuit, which outputs triangular wave pulse TCLK, first square wave pulse sequence PCLK1 and second square wave pulse sequence PCLK2 with relative phase difference, including three corresponding pulse output paths composed of field effect transistor circuits and inverter circuits ;

[0068] Multiple current mirror circuits whose outputs have fixed-biased currents;

[0069] A single pulse generating circuit, its two input ends are respectively connected to the output ends of the high-precision oscillation circuit and the multi-current mirror circuit, its output clock pulse modulates the triangular wave pulse TCLK and the current and outputs an alternating current pulse ;

[0070] The buffer frequency matching circuit receives the alternating current pulse output by the single pulse generating circuit;

[0071] A reference MEMS sensor that receives the relevant alternating current pulses output by the buffered frequency matching circuit and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com