Pigment powders

A technology of pigments, powders, used in the field of preparation of such pigment powders, cosmetics and other decorative formulations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

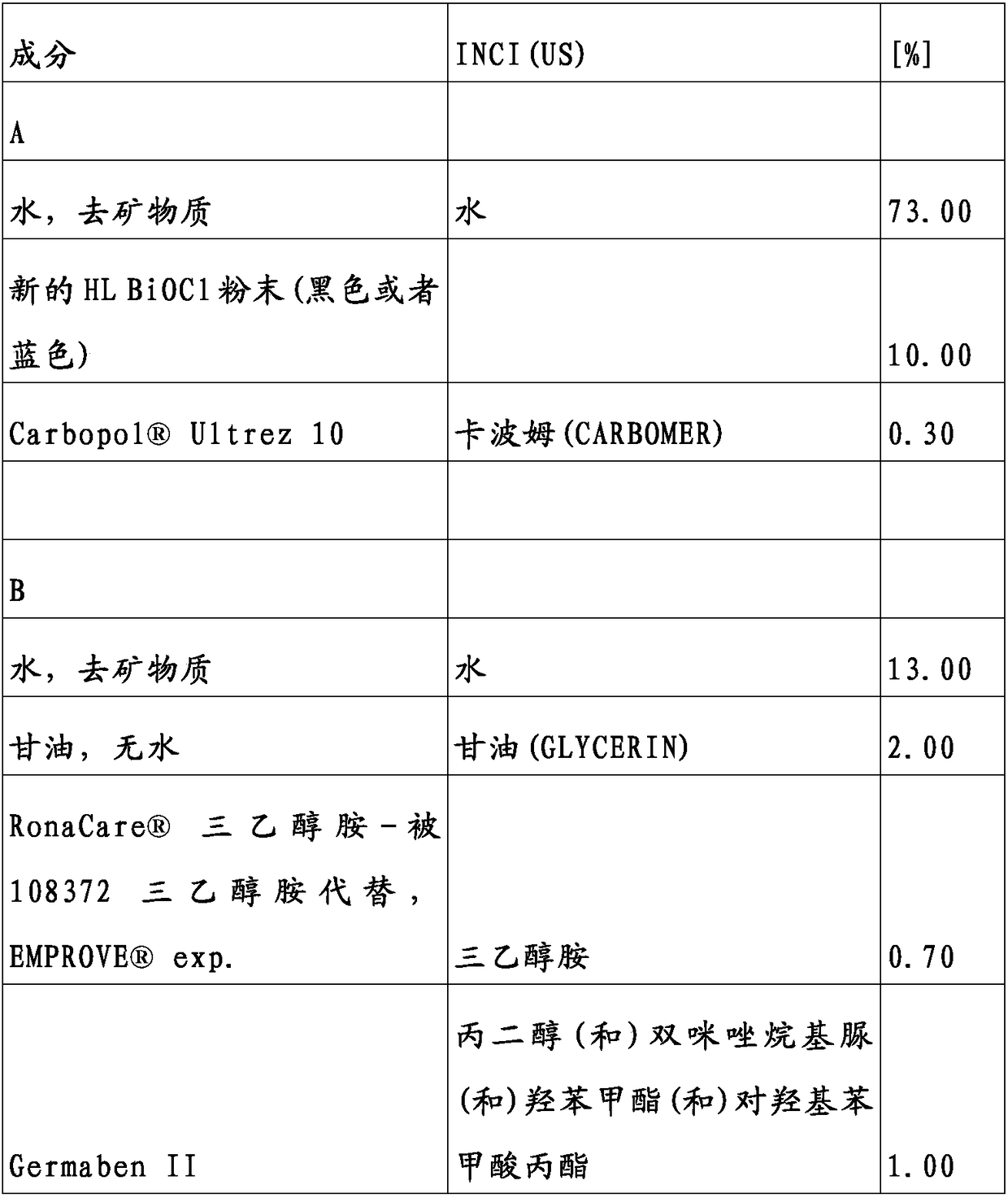

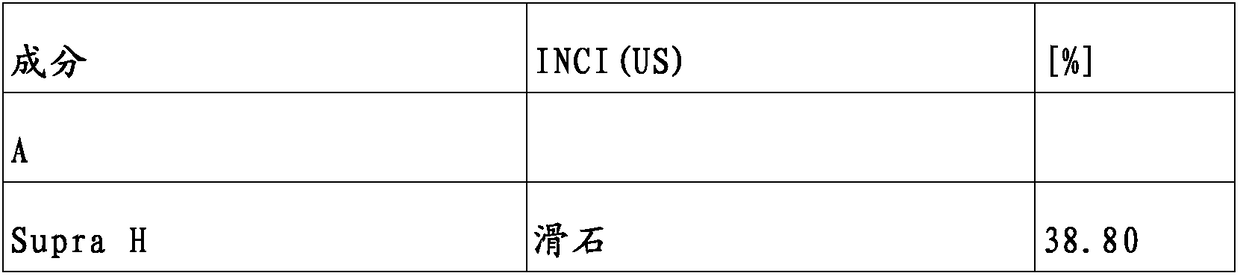

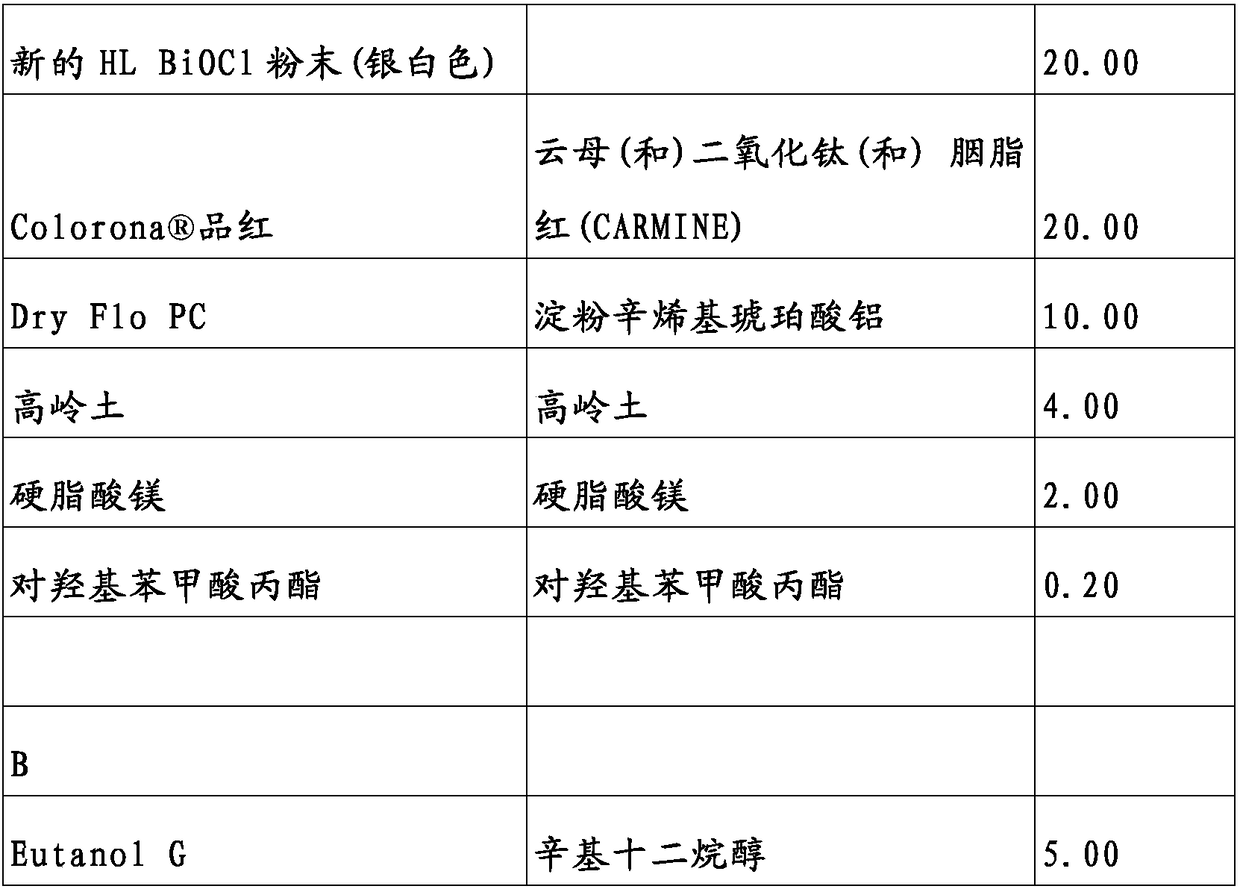

Method used

Image

Examples

Embodiment 1

[0119] A slurry of 100 g of high-gloss BiOCl flakes (thickness ~60 nm; particle size 8-20 μm, which washes away reaction by-products (salts and surfactants)) was adjusted to 3 wt% concentration in deionized water. The temperature was raised to 75°C with constant agitation vigorous enough to maintain a uniform suspension and dispersion of the feed solution throughout the reaction vessel. A solution of 85 g of ferric ammonium sulfate dodecahydrate in 300 mL of deionized water was fed into the slurry via a submerged inlet tube such that the pH dropped from neutral pH to 3.0 over 30-45 minutes during the initial feed rate . The remaining solution was delivered over 3 hours while the pH was kept close to 3.0 by concurrent co-feeding of 5% ammonia solution. The color of the paste changed from pearlescent silver to gold. Thereafter it will contain 5.5% SiO 2 The dilute sodium water glass solution was delivered slowly over approximately 4 hr until a pH of 6.0 was reached. The slur...

Embodiment 2

[0121] The procedure of Example 1 was repeated, but using 112 g of ferric ammonium sulfate dodecahydrate instead of 85 g of ferric ammonium sulfate dodecahydrate and omitting the final neutralization and SiO 2 , which resulted in a composite pigment in powder form comprising 100 g of BiOCl and 20 g of iron oxide as FeOOH.

Embodiment 3

[0123] The procedure of Example 2 was repeated, using 140 g of ferric ammonium sulfate dodecahydrate instead of 85 g of ferric ammonium sulfate dodecahydrate, which resulted in a composite pigment in powder form comprising 100 g of BiOCl, 25 g of iron oxide as FeOOH .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com