Water treatment porous membrane and preparation method thereof

A porous membrane and water treatment technology, which is applied in the direction of osmosis/dialysis water/sewage treatment, chemical instruments and methods, membranes, etc., can solve the problems of complex preparation process, poor durability, and poor hydrophilicity, so as to reduce manufacturing costs and improve Hydrophilic properties, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

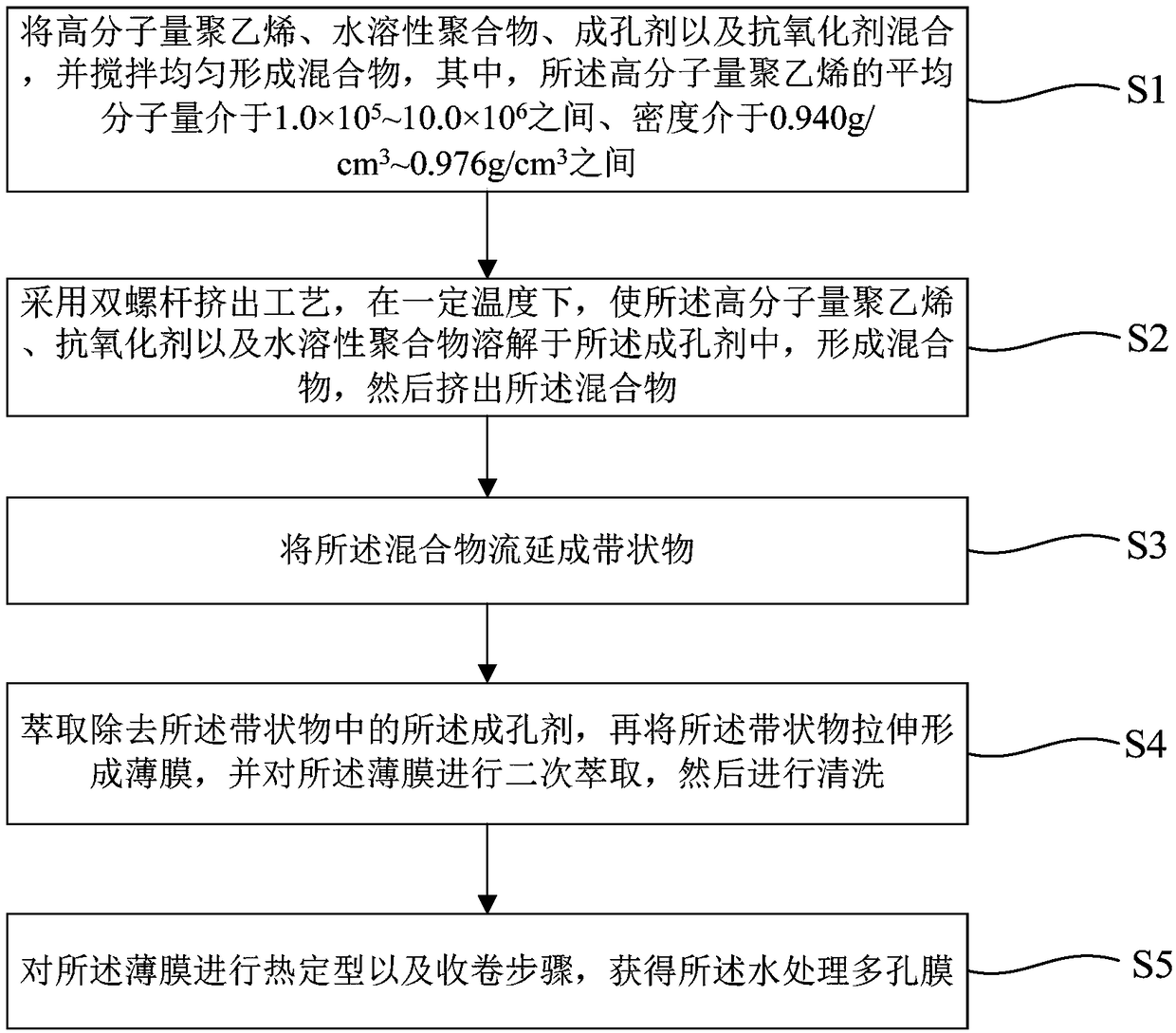

[0048] like figure 1 As shown, the present invention also provides a method for preparing a water treatment porous membrane. Using the preparation method, the above water treatment porous membrane can be prepared, and the preparation method at least includes:

[0049] S1, mixing high molecular weight polyethylene, water-soluble polymer, pore forming agent and antioxidant, and stirring uniformly to form a mixture, wherein the average molecular weight of the high molecular weight polyethylene is between 1.0×10 5 ~10.0×10 6 Between, the density is between 0.940g / cm 3 ~0.976g / cm 3 between;

[0050] S2, using a twin-screw extrusion process to dissolve the high molecular weight polyethylene, antioxidant and water-soluble polymer in the pore-forming agent at a certain temperature to form a mixture, and then extrude the mixture;

[0051] S3, casting the mixture into ribbons;

[0052] S4, extracting and removing the pore-forming agent in the strip, stretching the strip to form a f...

Embodiment 1

[0076] The density of 100 grams is 0.957g / cm 3 The average molecular weight is 5.0×105 High molecular weight polyethylene, 0.5 g antioxidant,

[0077] Add 5 grams of polyethylene oxide and 250 grams of mineral oil into the continuous batching feeder, stir at a speed of 50 rpm, and mix the raw materials evenly.

[0078] The mixture is continuously fed into the twin-screw extruder, and at 180°C, the high molecular weight polyethylene, antioxidant and polyethylene oxide are continuously dissolved in mineral oil in the twin-screw extruder, and then Continuously extrude at a speed of 200 rpm, the mixture continuously enters the slot die, the mixture is extruded through the slot die to casting cooling rolls, and cast into strips at 80°C.

[0079] Put the obtained ribbon into an extraction tank containing dichloromethane for extraction to remove the mineral oil in the ribbon. Afterwards, the extracted strips are continuously fed into a biaxial stretching machine at 120° C. to be st...

Embodiment 2

[0083] The density of 100 grams is 0.957g / cm 3 The average molecular weight is 5.0×10 5 High molecular weight polyethylene, 0.5 gram of antioxidant, 10 gram of polyoxyethylene, 250 gram of mineral oils are added in the continuous batching feed kettle, stir at a speed of 50 rpm, and the raw materials are mixed evenly.

[0084] The mixture is continuously fed into the twin-screw extruder, and at 180°C, the high molecular weight polyethylene, antioxidant and polyethylene oxide are continuously dissolved in mineral oil in the twin-screw extruder, and then Continuously extrude at a speed of 200 rpm, the mixture continuously enters the slot die, the mixture is extruded through the slot die to casting cooling rolls, and cast into strips at 80°C.

[0085] Put the obtained ribbon into an extraction tank containing dichloromethane for extraction to remove the mineral oil in the ribbon. Afterwards, the extracted strips are continuously fed into a biaxial stretching machine at 120° C. t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com