Gas-hydrate-method seawater desalination system

A hydrate and gas technology, applied in seawater treatment, water/sewage treatment, water/sewage treatment equipment, etc., can solve problems such as cost, process and efficiency limitations, difficult operation, complex equipment, etc., to improve the degree of seawater desalination, Improve the effect of desalination and improve the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

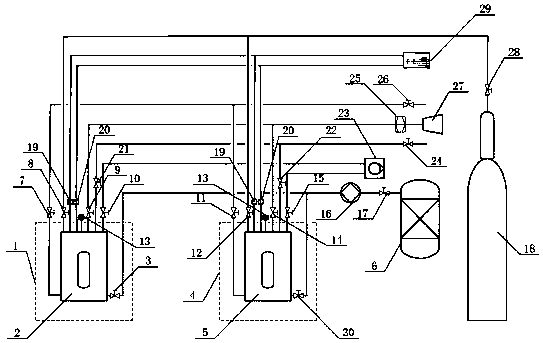

[0020] The present invention will be further explained below in conjunction with the drawings:

[0021] Such as figure 1 Shown: the present invention includes a first reaction kettle 2, a second reaction kettle 5, the first reaction kettle and the second reaction kettle are respectively placed in the first constant temperature water bath 1 and the second constant temperature water bath 4, the first reaction kettle passes The third valve 8, the seventeenth valve 28 is connected to the gas cylinder 18, the second reactor is connected to the gas cylinder through the seventh valve 12, the seventeenth valve; the first reactor is connected to the gas cylinder through the fifth valve 10, the gas circulation pump 23, The ninth valve 15 is connected to the second reactor; the axial flow pump 16 is connected to the liquid storage tank 6 through the eleventh valve 17; the tops of the first reactor and the second reactor are equipped with a stirring device 13, and the first reactor and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com