Gas circulating and stirring plug-flow type anaerobic fermentation reaction device

A gas circulation and anaerobic fermentation technology, applied in biological sludge treatment, animal husbandry wastewater treatment, etc., can solve the problems of high operating energy consumption, easy precipitation and stratification, poor material mass transfer, etc., and achieves good effect and uniform mixing. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

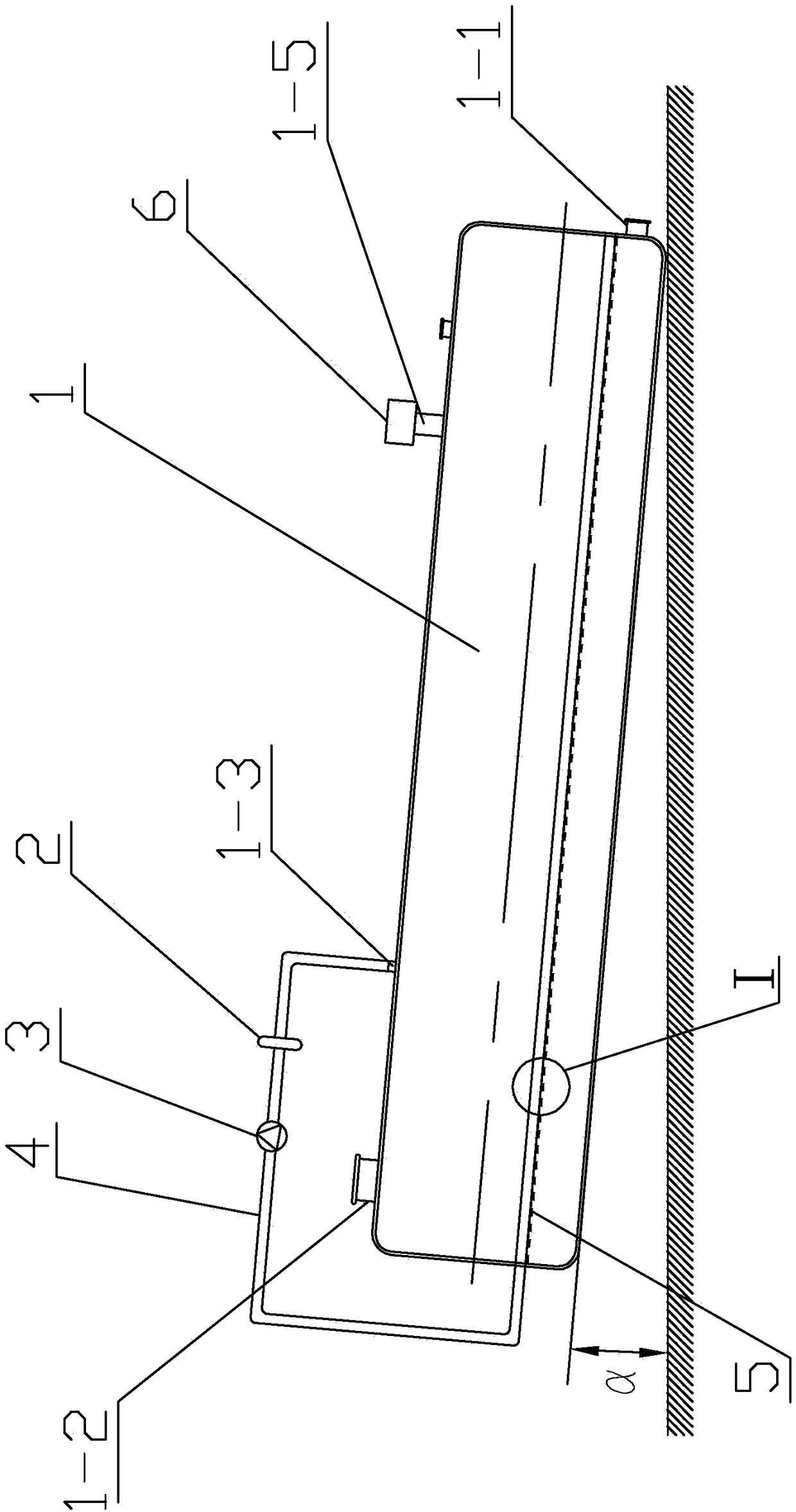

[0016] Specific implementation mode one: combine figure 1 To illustrate this embodiment, this embodiment includes a fermenter body 1, a dehumidifier 2, a gas booster pump 3, a gas circulation pipeline 4 and a plurality of nozzles 5;

[0017] The fermentation tank body 1 forms a certain angle α with the horizontal plane, and the fermentation tank body 1 is provided with a discharge port 1-1, a feed port 1-2, an air outlet 1-3 and a gas collection port 1-5, and a feed port 1- 2 and the discharge port 1-1 are provided with valves, the gas collection port 1-5 is provided with a gas collection device 6, one end of the gas circulation pipeline 4 is connected with the gas outlet 1-3, and one end of the gas circulation pipeline 4 extends into the fermentation Inside the tank body 1 , a plurality of nozzles 5 are provided on the gas circulation pipeline 4 extending into the fermentation tank body 1 , and a dehumidifier 2 and a gas booster pump 3 are provided on the gas circulation pipe...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the angle α between the fermenter body 1 and the horizontal plane in this embodiment is 3°-5°.

[0019] Such setting is to ensure that the material is stirred evenly, and at the same time, the material is moved downward for a certain distance, so that the fermented waste is discharged through the discharge port 1-1, and at the same time, the waste fermented material will not be fermented. The storage in the tank body 1 better guarantees the effect of fermentation.

[0020] Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the fermenter body 1 in this embodiment is a cylindrical tank body, and the ratio of its diameter to length is 1:4 or 1:5.

[0022] Such setting is to improve the plug flow effect, so that the material is discharged from the outlet 1-1 of the fermenter body 1 in the form of air blowing.

[0023] Other compositions and connections are the same as in the first embodiment.

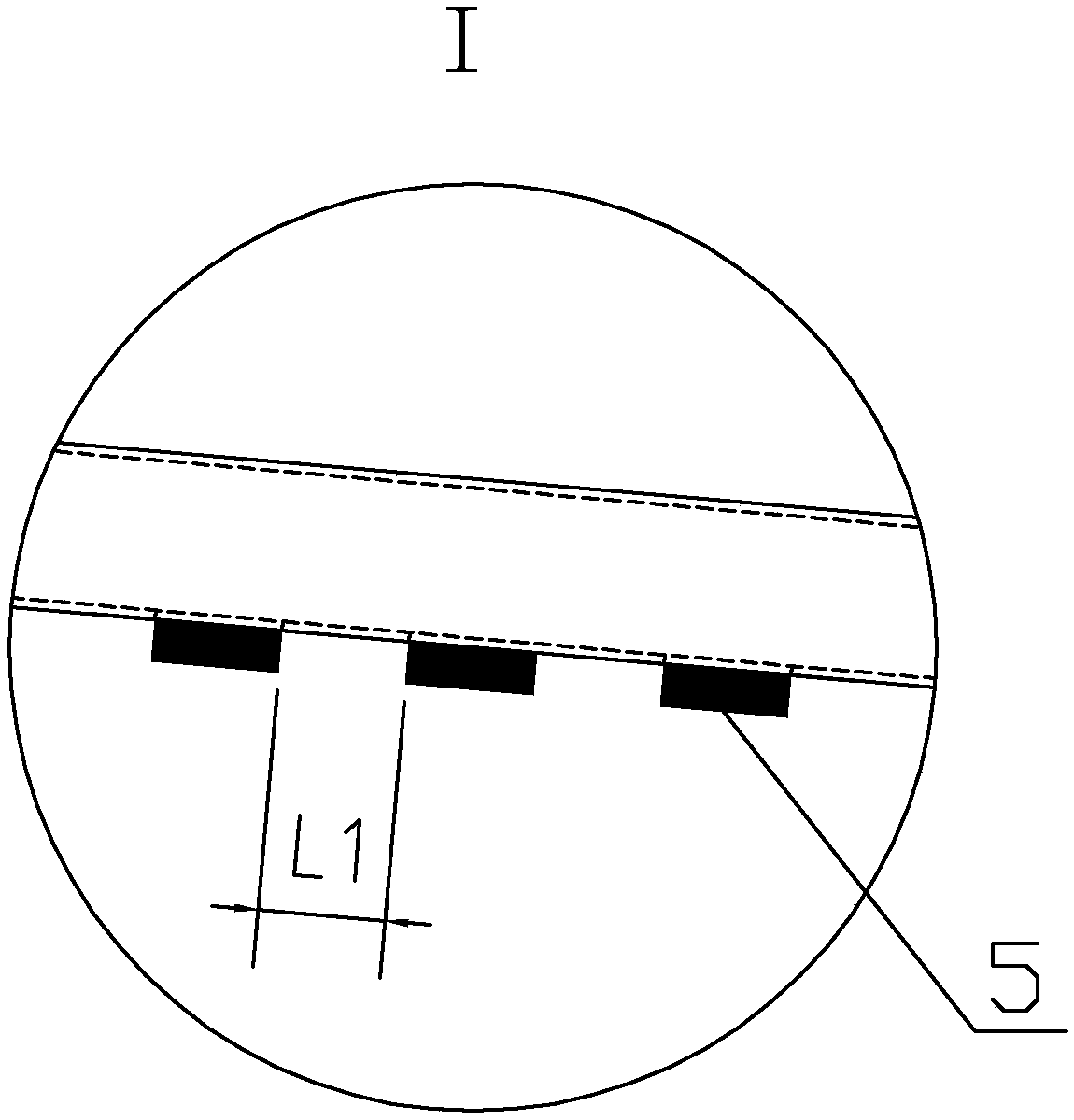

[0024] Specific implementation mode four: combination figure 1 To illustrate this embodiment, the gas circulation pipeline 4 extending into the fermentation tank body 1 described in this embodiment is arranged parallel to the centerline of the fermentation tank body 1, and the gas circulation pipeline 4 extending into the fermentation tank body 1 is set 1 / 3 below the centerline of the fermenter body 1.

[0025] This setting is to keep a certain distance between the air nozzle and the material, so that the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com