Method for producing methane through fungal solid-state fermentation of kitchen waste

A food waste and solid-state fermentation technology, which is applied in the field of food waste treatment, can solve the problems of reducing the specific surface area of contact between the substrate and microorganisms, increasing the cost of methane production, and low utilization of the substrate, so as to speed up the speed of hydrolysis and liquefaction, reduce the The cost of methane production and the effect of improving substrate utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

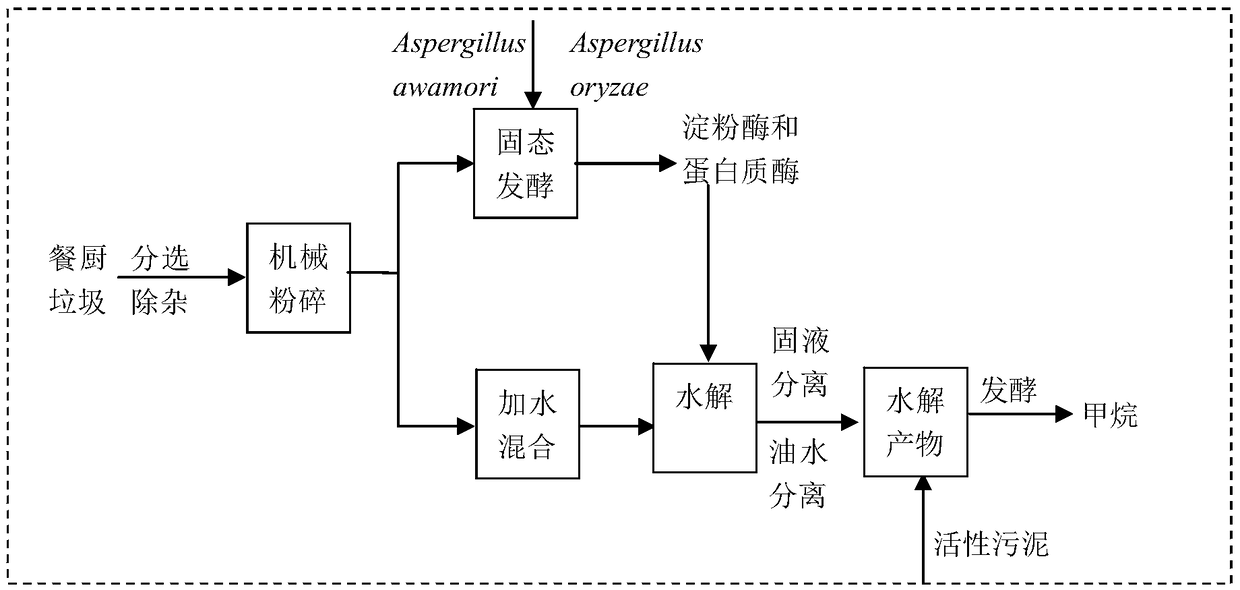

[0032] The technical solutions provided by the present invention will be further described below in conjunction with the accompanying drawings.

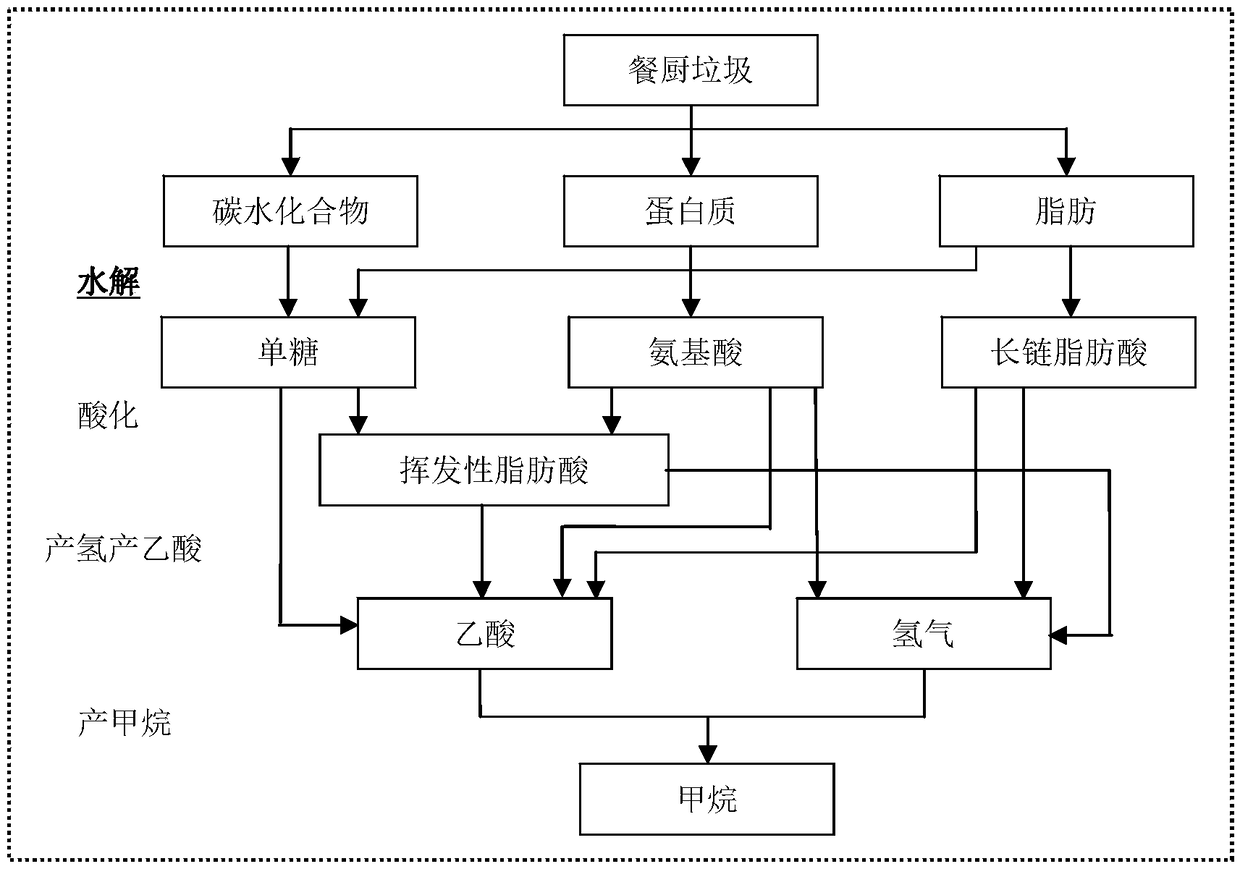

[0033] see figure 2 , which is a flow chart of a method for producing methane by using fungal solid-state fermentation of food waste provided by the present invention, comprising the following steps:

[0034] Step S1: Sorting and removing a certain amount of kitchen waste and mechanically crushing it to form kitchen waste to be processed;

[0035] Step S2: Select 5%-20% of the food waste to be treated formed in step S1, add the fungi Aspergillus awamori and Aspergillus oryzae for solid-state fermentation to cultivate solid substances rich in amylase and proteinase, and convert the rest of the food waste to be treated Food waste is mixed with water to form mixed water food waste;

[0036] Wherein, the process of solid-state fermentation is to add fungal solution to the food waste to be fermented in proportion to carry out solid-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com