A kind of preparation method of iron-rich coating on the surface of magnesium alloy

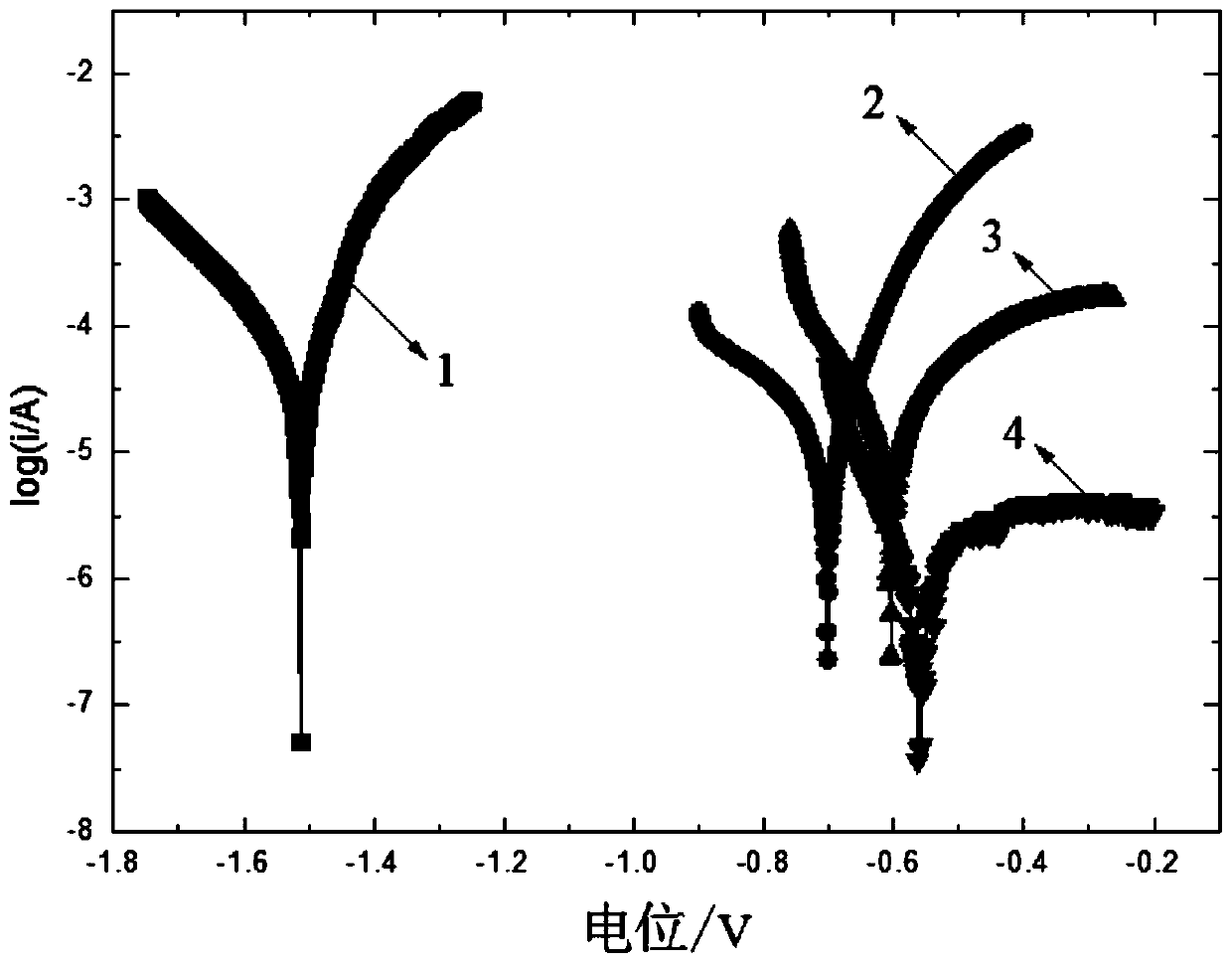

A magnesium alloy and coating technology, applied in the direction of metal material coating process, coating, liquid chemical plating, etc., can solve the problem of poor corrosion resistance of magnesium alloys, and achieve the improvement of corrosion resistance, experimental equipment and experimental reagents. Less experimental equipment and experimental reagents are easily available

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

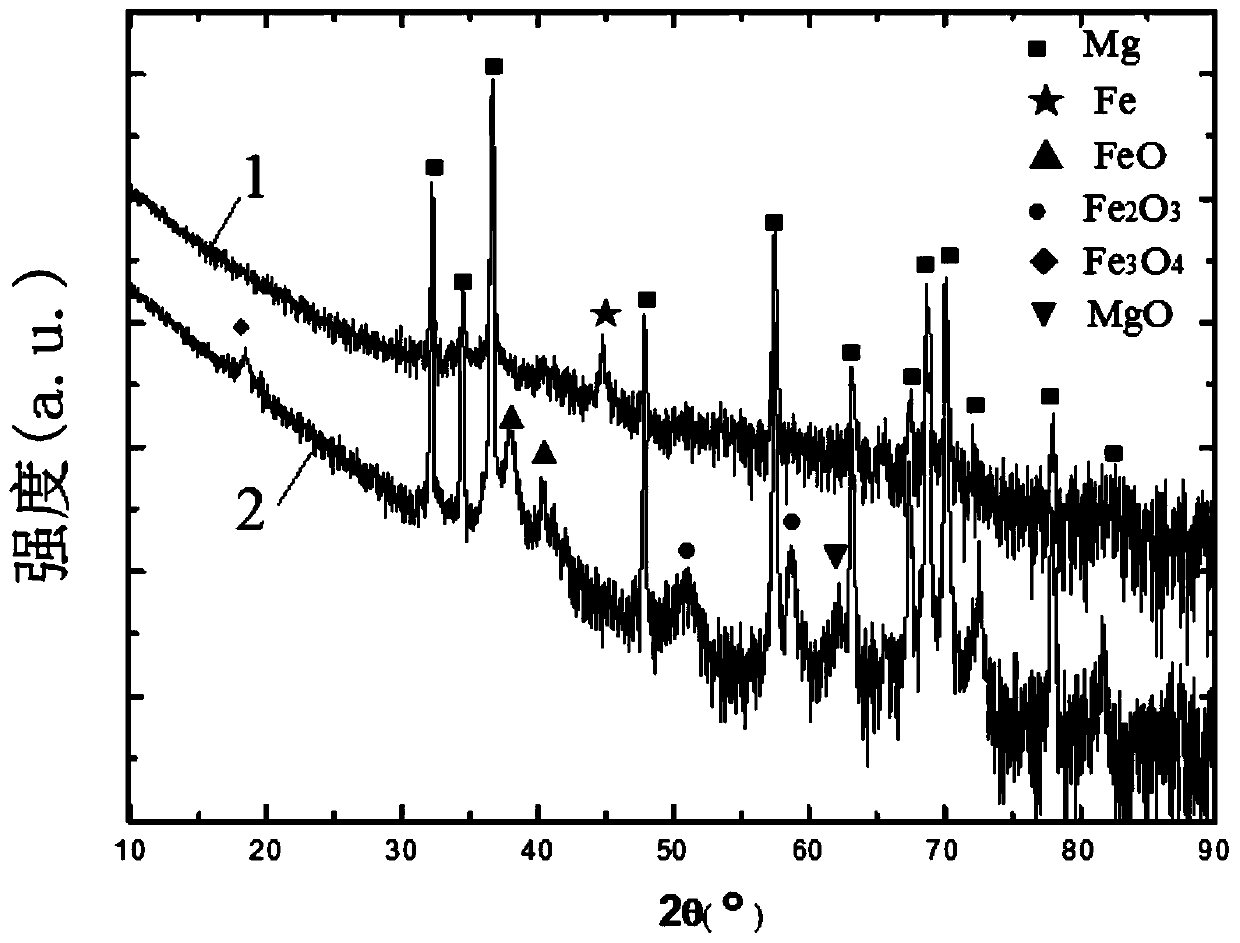

Examples

specific Embodiment approach 1

[0023] Embodiment 1: This embodiment is a method for preparing an iron-rich coating on the surface of a magnesium alloy, which is specifically completed according to the following steps:

[0024] 1. Use 600# sandpaper and 2000# sandpaper to polish the surface of the magnesium alloy substrate in sequence until the surface of the magnesium alloy substrate is smooth, then remove the oil stain on the surface of the magnesium alloy substrate, and then use deionized water to rinse the surface of the magnesium alloy substrate to remove the oil stain 3 to 5 times, and finally use a hair dryer to dry to obtain a polished magnesium alloy;

[0025] 2. ①. Soak the polished magnesium alloy in the reduction deposition solution for 30s~60s, take it out, wash it with absolute ethanol for 3~5 times, and then use a hair dryer to dry it;

[0026] ②, repeat step 2 ① 5 to 20 times to obtain the deposited magnesium alloy;

[0027] ③. React the deposited magnesium alloy in the ferrous sulfate solut...

specific Embodiment approach 2

[0036] Embodiment 2: This embodiment differs from Embodiment 1 in that: the magnesium alloy substrate described in step 1 is MB15 magnesium alloy. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the reduction deposition solution described in step 2 ① is 75g / L~150g / L FeSO 4 ·7H 2 O solution. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com