Novel fabricated transformation type anti-buckling energy dissipation support and manufacturing technology

A new technology of anti-buckling energy dissipation, applied in earthquake resistance, building type, protective buildings/shelter, etc., can solve the problem of poor buckling energy dissipation performance of welding core material, poor durability and seismic performance, residual deformation, etc. problem, to achieve the effect of high economy, convenient production and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

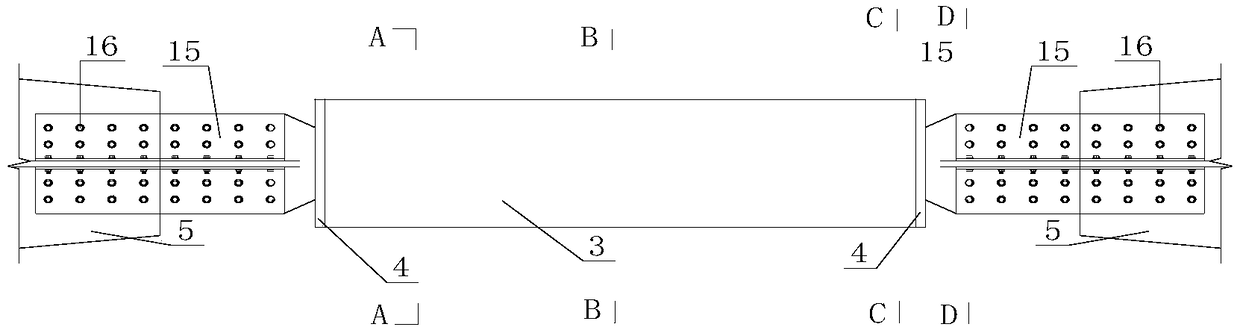

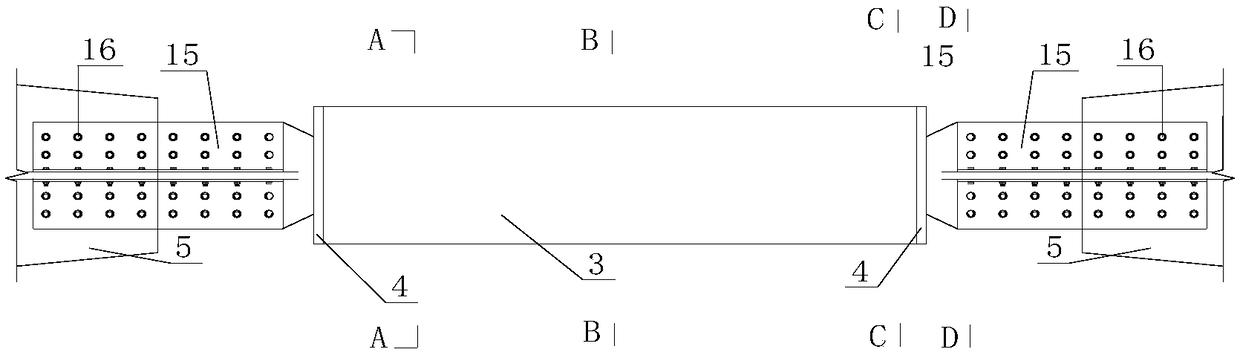

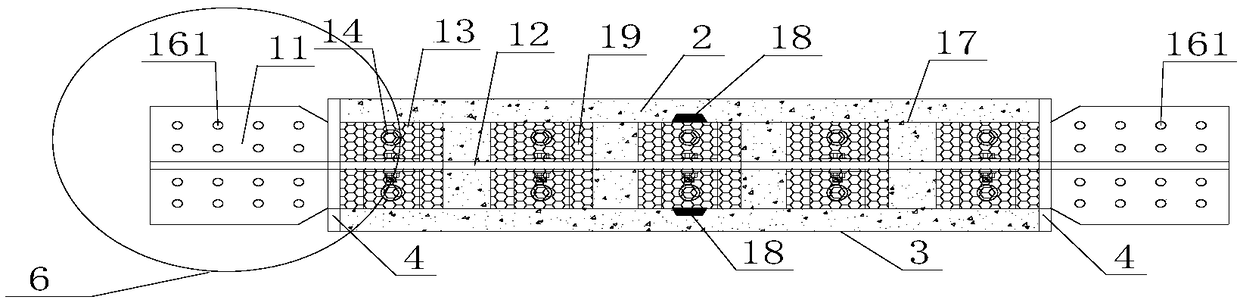

[0053] Example 1: Reference Figure 1 to Figure 11 , The present invention is a new assembly conversion type anti-buckling energy-consuming support, including a main core material 11, a secondary core material 12, a main structure 5, a restraining unit located at the periphery of the main core material and the secondary core material, which are used to connect the main core material The connecting plate 13 and the connecting bolt 14 of the secondary core material are used to connect the structural connecting plate 15 and the structural connecting bolt 16 supporting the main structure, the non-bonded material 17, and the compressed material 19; the restraining unit includes the sleeve 3, the cover Plate 4 and grouting material 2, wherein the main core material and the secondary core material are located in the sleeve, the two ends of the sleeve are equipped with cover plates to form a closed cavity, and the closed cavity is filled with grout to obtain The core force unit; the co...

Embodiment 2

[0055] Embodiment 2: The present invention also provides another technical solution: a manufacturing process of a novel assembly conversion type anti-buckling energy-consuming support, including the following steps:

[0056] (1) Prepare to process the main core material, secondary core material, casing, cover plate, connecting plate, structural connecting plate, grouting material, blank material and high-strength bolts of unbonded material of compressed material.

[0057] (2) Through the cutting method, the blank steel plate is made into the size of the main core material and the auxiliary core material of the support, and then the connecting bolt hole 1 and the structural connecting bolt hole are opened on the main core material and the auxiliary core material;

[0058] (3) Cut the blanks used to make the connecting plate into a rectangular connecting plate and a prototype of the structural connecting plate, and then make the embryonic form into a connecting plate and a structural co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com