Calendering device

A technology of calendering device and pressing roller, which is applied in the direction of electrode rolling/calendering, structural parts, electrical components, etc., can solve the problems of battery core lithium analysis, lithium strip thickness fluctuation, and lithium strip weight consistency, etc., to achieve uniform thickness, The effect of improving uniformity and ensuring weight consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

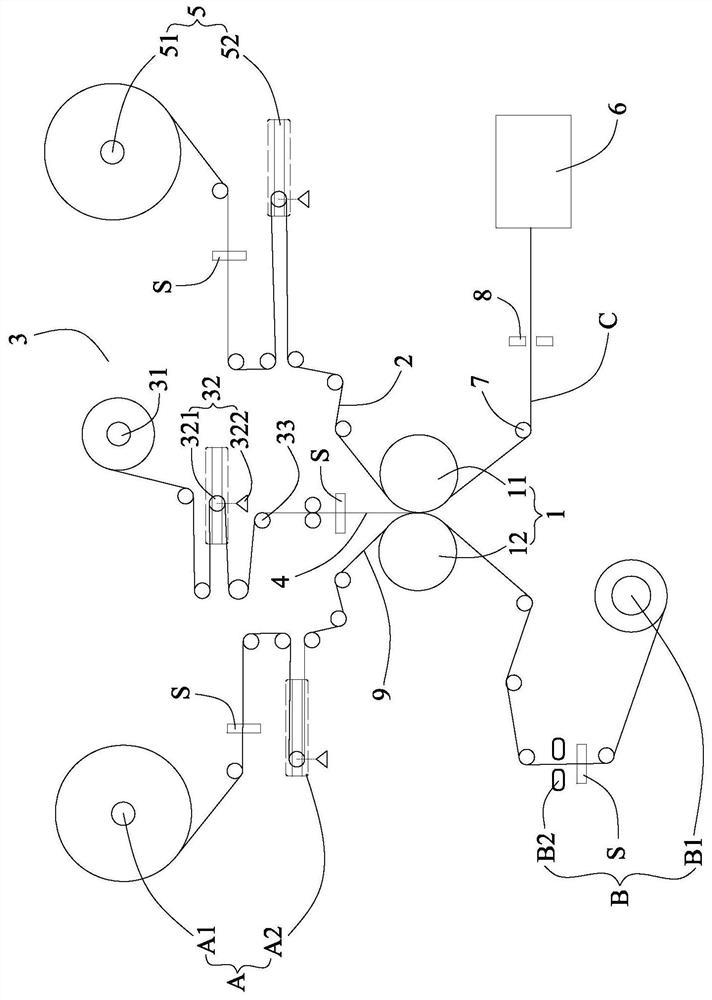

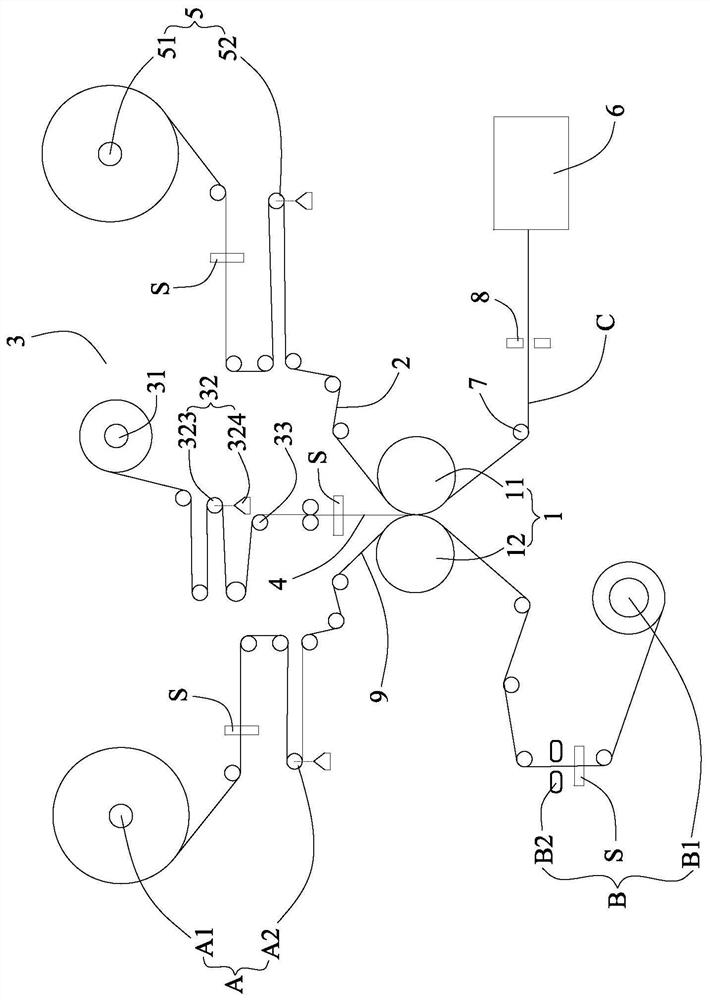

[0025] The calendering apparatus of the present invention will be described in detail below with reference to the drawings.

[0026] refer to figure 1 and figure 2 , the calendering device according to the present invention comprises: a rolling mechanism 1, comprising a first press roller 11 and a second press roller 12 arranged in parallel; a base material 2, attached to the first press roller 11 and moving forward; Mechanism 3; Material belt 4 is arranged on the material belt unwinding mechanism 3 and is sent into the rolling mechanism 1 by the material belt unwinding mechanism 3, and adheres to it under the extrusion of the first pressure roller 11 and the second pressure roller 12 on substrate 2. The tape unwinding mechanism 3 includes a tape unwinding shaft 31, a tape tension detection assembly 32 and a tape speed detection assembly 33, and the tape 4 wound on the tape unwinding shaft 31 passes through the tape tension detection assembly 32 and the tape speed detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com