Arm frame type trawler

A trawler and boom technology, which is applied in the directions of fishing boats, generators/motors, engines, etc., can solve the problems of easy toppling of fishing boats, poor stability of fishing boats, and high center of gravity of fishing boats, so as to improve safety, suppress vibration, reduce The effect of a momentary shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention combined with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

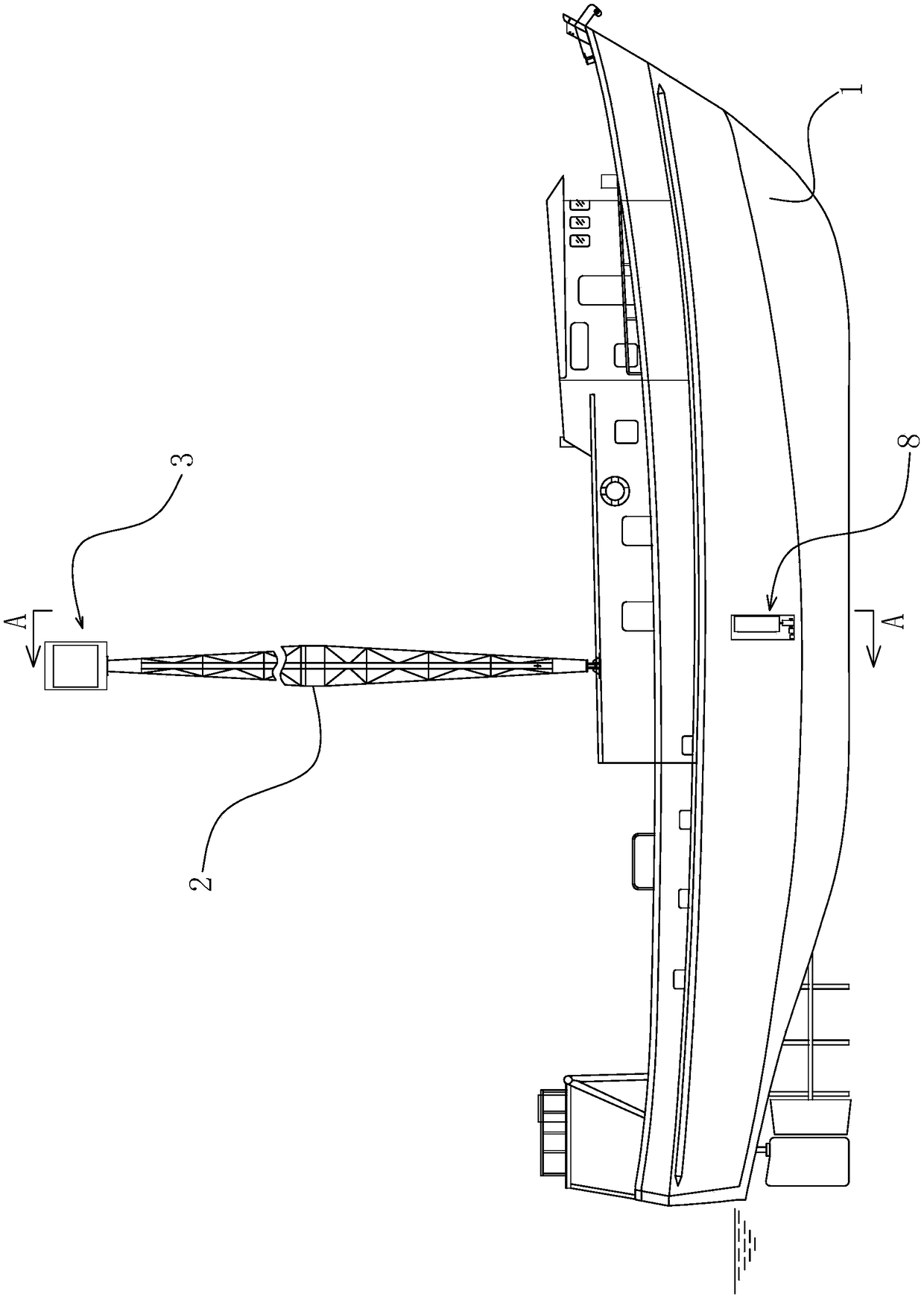

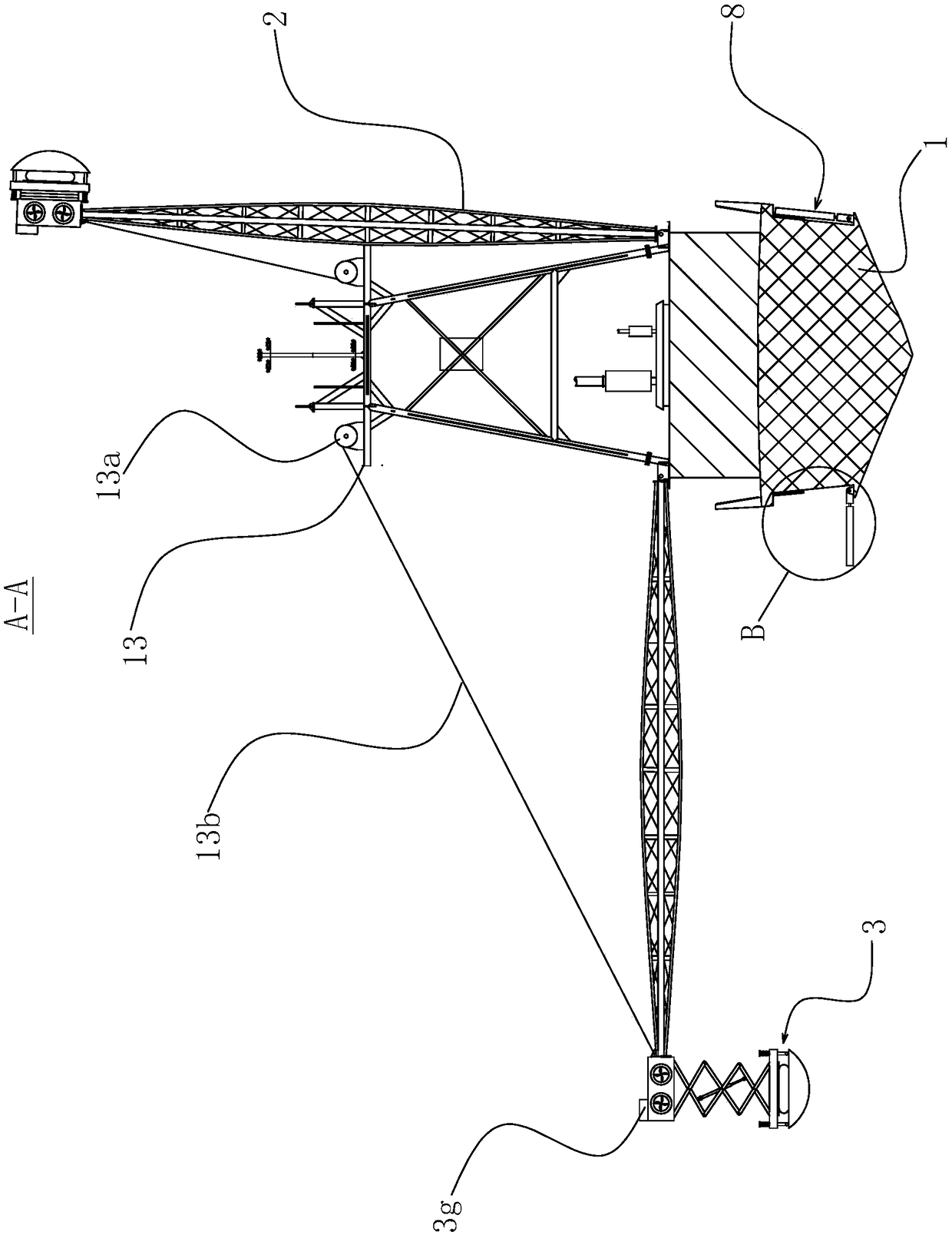

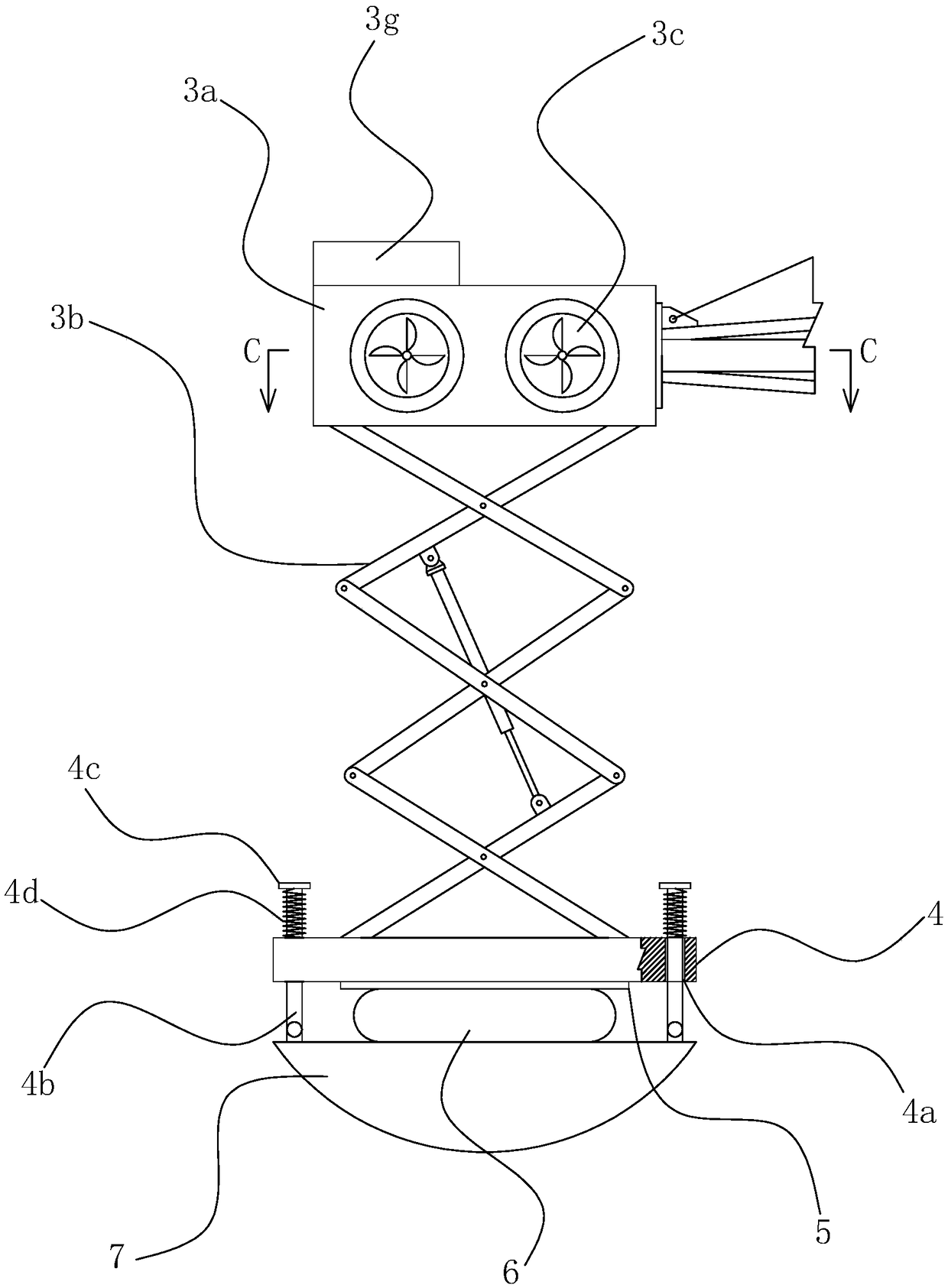

[0033] Such as Figure 1 to 4 As shown, a boom-type trawler includes a hull structure 1 and two trawl booms 2. The lower ends of the two trawl booms 2 are hinged on both sides of the hull structure 1, and the top of the trawl boom 2 A floating mechanism 3 is provided. The floating mechanism 3 includes a floating box 3a. The lower side of the floating box 3a is provided with a hydraulic lifting platform 3b, and the lower end of the hydraulic lifting platform 3b is provided with a lifting plate 4, the lifting plate 4 A through hole 4a is opened on the periphery of the through hole 4a, and a sliding rod 4b is inserted in the through hole 4a. The upper end of the sliding rod 4b is provided with a baffle 4c. The size of the baffle 4c is larger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com