Palygorskite clay based multifunctional assistant of macromolecular materials and preparation method for palygorskite clay based multifunctional assistant

A technology of palygorskite clay and functional polymers, applied in the field of palygorskite clay-based polymer material additives and its preparation, and polymer material additives, which can solve the problems of low impact performance and low impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Grind palygorskite clay to more than 4000 mesh, add 1-15% of its mass silane coupling agent, and stir at high speed for 1 hour to obtain modified surface palygorskite clay, dry and crush again to more than 4000 mesh ;

[0022] Take a certain amount of surface-modified palygorskite clay and disperse it into ethyl acetate solvent to make the mass concentration 60%; then add the compound 1-propylphosphoric anhydride (CAS: 68957-94-8), the compound 5-aminotetrazolium (CAS: 4418-61-5) with 60% palygorskite clay on a dry basis, was first ultrasonically dispersed for 30-120 min, then mechanically stirred for 1 hour; then air flow Dry and recover the ethyl acetate solvent (recycle) to obtain a powder product; finally, grind the powder product in a ball mill at high speed for 0.5 hours to obtain a multifunctional polymer synthetic material additive.

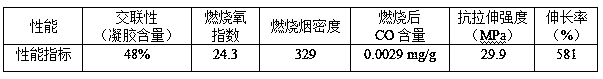

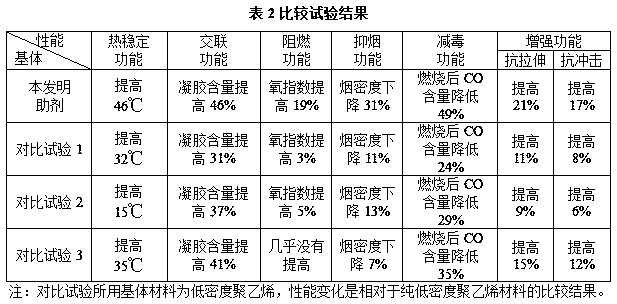

[0023] The auxiliary agent is used for the preparation of low-density polyethylene-based composite materials. When the additive ...

Embodiment 2

[0026] Grind palygorskite clay to more than 4000 mesh, add 1-15% of its mass silane coupling agent, and stir at high speed for 1 hour to obtain modified surface palygorskite clay, dry and crush again to more than 4000 mesh ;

[0027] Take a certain amount of surface-modified palygorskite clay and disperse it into ethyl acetate solvent to make the mass concentration 60%; then add the compound 1-propylphosphoric anhydride (CAS: 68957-94-8), the compound 5-aminotetrazolium (CAS: 4418-61-5) with 80% dry weight of palygorskite clay, first ultrasonically dispersed for 30~120min, then mechanically stirred for 3 hours; then air-dried The ethyl acetate solvent is recovered (recycled) to obtain a powder product; finally, the powder product is ground in a ball mill at high speed for 0.2 hours to obtain a multifunctional polymer synthetic material additive.

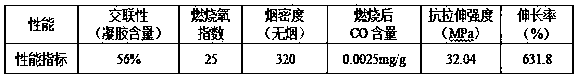

[0028] The auxiliary agent is used for the preparation of low-density polyethylene-based composite materials. When the additive am...

Embodiment 3

[0031] Grind palygorskite clay to more than 4000 mesh, add 1-15% of its mass silane coupling agent, and stir at high speed for 1 hour to obtain modified surface palygorskite clay, dry and crush again to more than 4000 mesh ;

[0032] Take a certain amount of surface-modified palygorskite clay and disperse it into ethyl acetate solvent to make the mass concentration 60%; then add the compound 1-propylphosphoric anhydride (CAS: 68957-94-8), the compound 5-aminotetrazolium (CAS: 4418-61-5) with 30% palygorskite clay dry basis, ultrasonically dispersed for 30-120min, then mechanically stirred for 2 hours; then air-dried The ethyl acetate solvent is recovered (recycled) to obtain a powder product; finally, the powder product is ground in a ball mill at high speed for 0.4 hours to obtain a multifunctional polymer synthetic material additive.

[0033]The auxiliary agent is used for the preparation of low-density polyethylene-based composite materials. When the additive amount is 3% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com