SHS metallurgy powder used for repairing 15CrMoQ pipe die and using method thereof

A metallurgical powder and pipe mold technology, which is applied in metal material coating process, coating, etc., can solve the problems of inability to adapt to pipe mold repair, cumbersome operation, and high cost of laser cladding, so as to reduce repair cost, improve repair quality, The effect of improving the absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

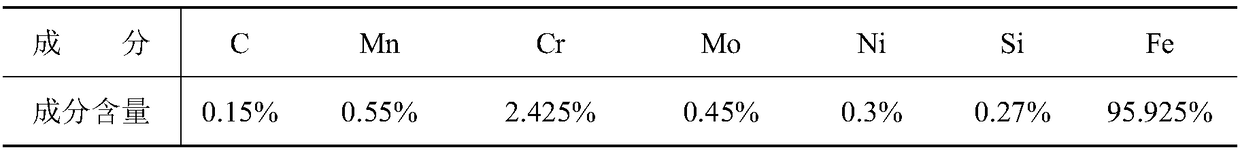

[0029] A kind of SHS metallurgical powder that is used for 15CrMoQ pipe mold repair, comprises following proportioning by weight: Fe 2 o 3 137.146 parts, Al 46.339 parts, CaO 5.7508 parts, FeSi90Al1.5 0.9327 parts, multi-alloy element additions 3.725 parts.

[0030] The multi-alloying element additions include Mn, Cr, Mo, and Ni; the multi-alloying element additions are obtained by either directly adding the corresponding metal simple substance or undergoing a substitution reaction with the corresponding metal oxide.

[0031] The direct addition of the corresponding metal element includes the following proportions by weight: Mn accounts for 0.55 parts, Cr accounts for 2.425 parts, Mo accounts for 0.45 parts, and Ni accounts for 0.3 parts.

[0032] The displacement reaction equation wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com