Long-drilled long-hole coal seam sub-stage fracturing enhancement and gas extraction method in underground coal mines

A segmented fracturing and long drilling technology, which is applied to drilling equipment and methods, gas discharge, earthwork drilling, etc., can solve the problems of long drilling hole collapse, complicated process, and small fracturing range, so as to prevent Effects of deformation and collapse holes, increasing the range of influence, increasing the range of anti-reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

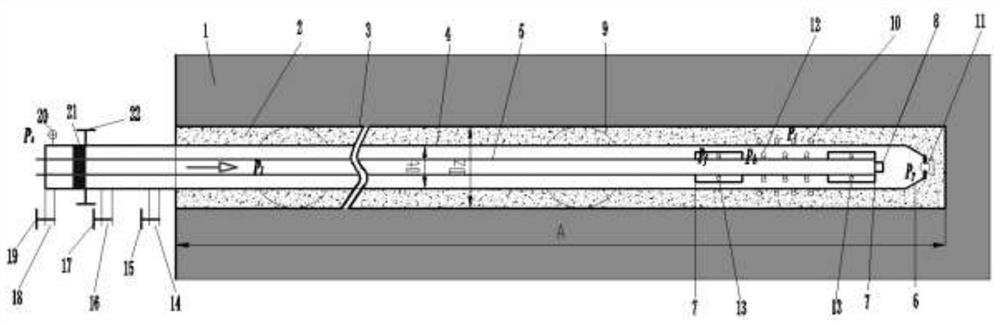

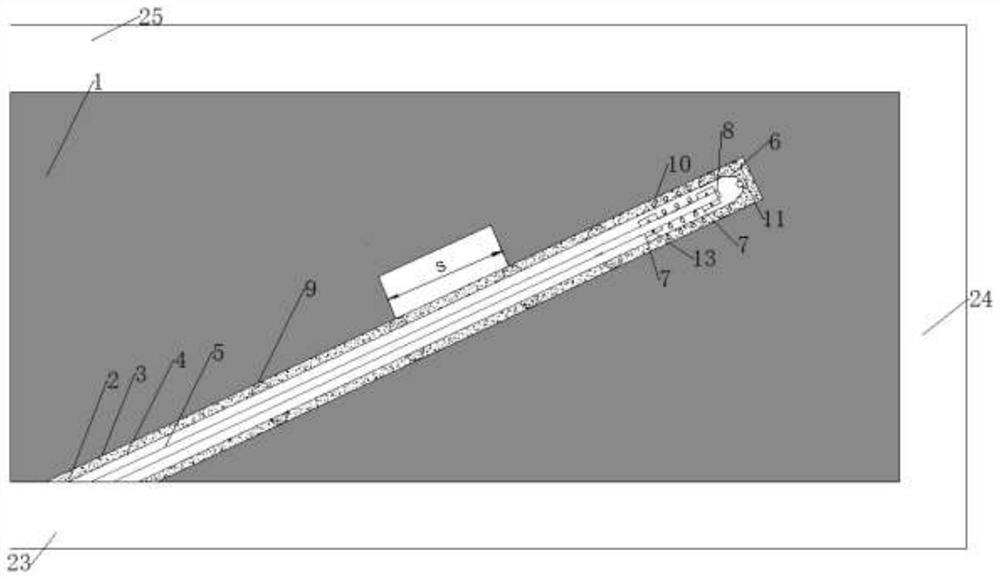

[0038] Such as figure 1 with figure 2 As shown, the coal mine tunnel drilling rig is used to drill a long borehole 3 with a length of 300 m and a diameter of 120 mm into the coal seam 1 in the wind inlet trough 23 of the mining face. After the long borehole 3 is drilled to a predetermined length, immediately use Clear water cleans the pulverized coal in the long borehole 3.

[0039] After the long borehole 3 is completed and cleaned, the tunnel drilling rig used in coal mines is immediately used to lower the guide shoe 6 provided with the check valve 11 and the rigid sleeve 4 provided with the check valve 10. The rigid sleeve 4 has the function of protecting the hole. The diameter of the rigid casing 4 is 90 mm, the opening pressure of the check valve 10 is 8 MPa, and the opening pressure of the check valve 11 is 4 MPa; in order to reduce the eccentricity of the casing string, install the rigid casing 4 every certain length S Casing centralizer9.

[0040] After the guide s...

Embodiment 2

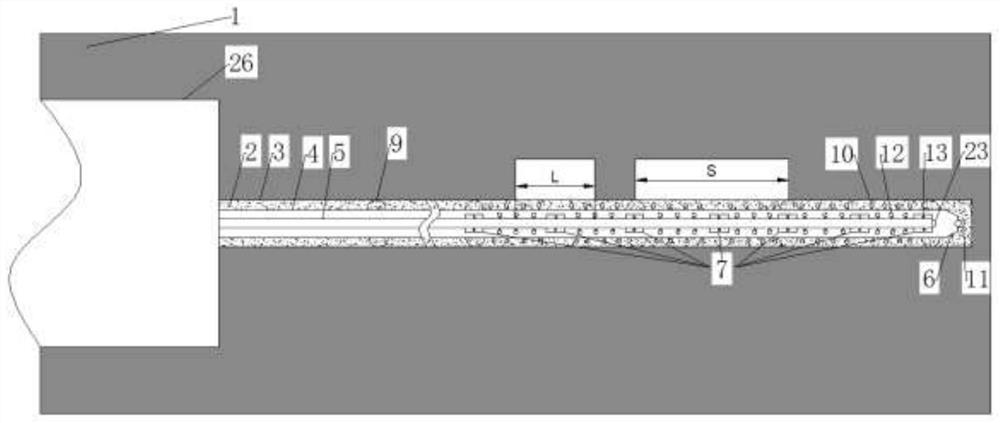

[0047] Such as figure 1 with image 3 As shown, the coal mine kilometer drill is used to drill the long borehole 3 with a length of 600m and a diameter of 153mm in the coal seam 1 in the tunneling head 26. Clean the coal powder in it.

[0048] After the long borehole drilling is completed and cleaned, immediately adopt the thousand-meter drilling rig for coal mines to go down into the guide shoe 6 that is provided with a check valve 11 and the rigid sleeve 4 that is provided with a check valve 10. The diameter of the rigid sleeve 4 is 115mm, the opening pressure of check valve 10 is 8MPa, and the opening pressure of check valve 11 is 4MPa; in order to reduce the eccentric phenomenon of the casing string, casing centralizers are installed every certain length S during casing running.

[0049] After the guide shoe 6 and the rigid casing 4 are lowered into the bottom of the long borehole, the grout switch 17 is turned on, and a set volume of grout is injected under pressure int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com