Equipment and method for exploiting coalbed methane by kilometer drilling and subsection water explosion fracturing

A coalbed methane and 1,000-meter drilling rig technology, which is applied to drilling equipment and methods, drilling equipment, and mining fluids, can solve problems such as coal mining equipment being uneconomical, increasing the range of fracturing, and less water resources, so as to improve fracturing The effect of increasing the scope of penetration, reducing the amount of construction, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

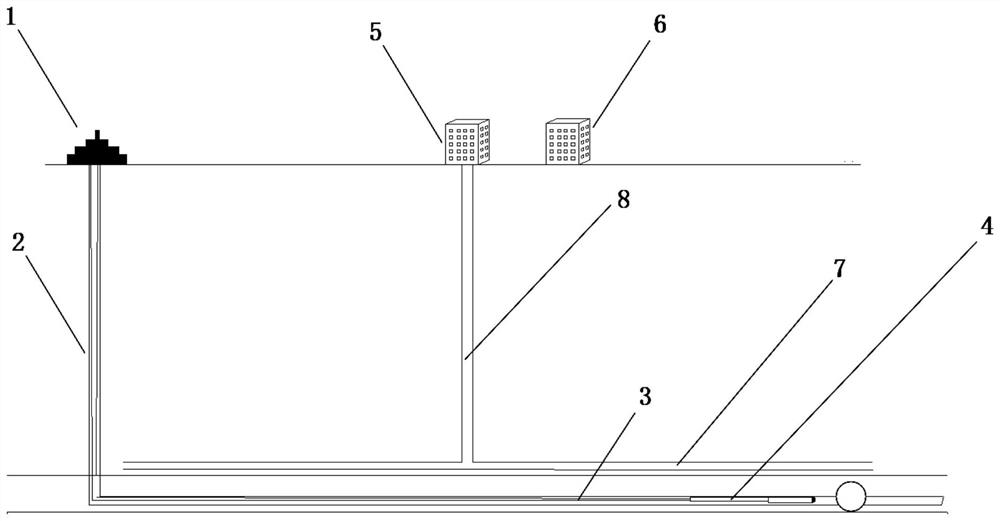

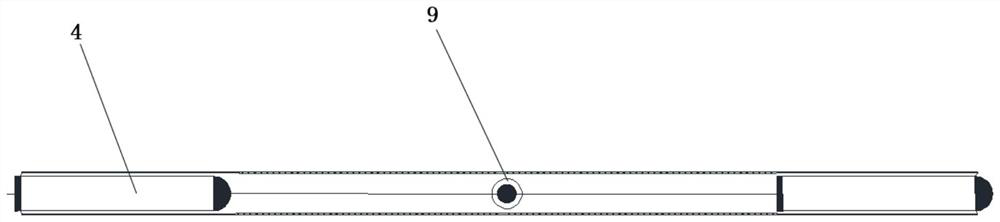

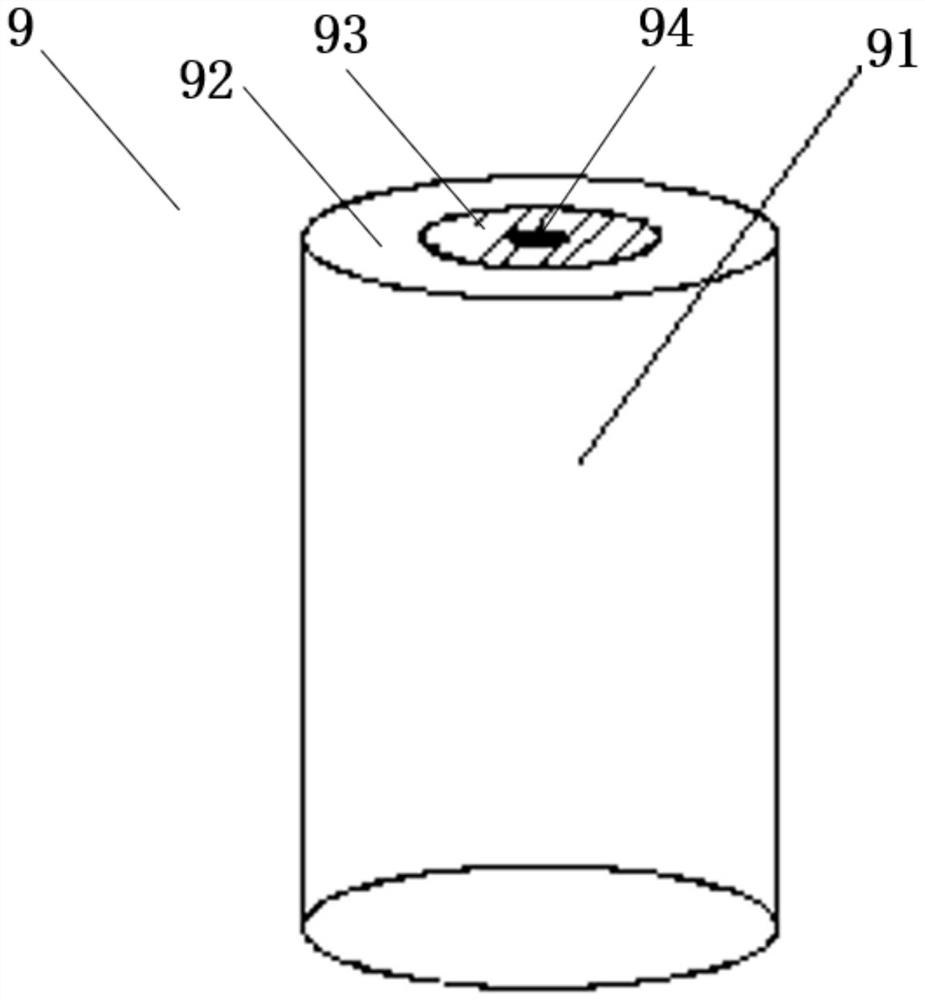

[0044] Such as figure 1 As shown, a kind of equipment for mining coalbed methane by segmental water explosion fracturing of a thousand-meter borehole includes a thousand-meter drilling rig 1, which excavates to form a vertical borehole 2 and intersects the vertical borehole 2 The horizontal borehole 3, and the high pumping roadway 7 that does not intersect with the vertical borehole 2, the horizontal borehole 3 is located in the coal seam, and several hydrothermal cracking cylinders 4 are arranged in the horizontal borehole 3, the The hydrothermal fracturing cylinder 4 is externally connected with a detonator, and the high pumping lane 7 is located on the center line of the blast fracture zone above the coal seam, and the high pumping lane 7 is vertically provided with a roadway 8 connected with the high pumping lane 7. An air extraction pipe is provided in the roadway 8, and the air extraction pipe is connected with the air extraction station 5 on the ground, and the air extr...

Embodiment 2

[0051] A method for mining coalbed methane by staged water explosion fracturing, comprising the following steps:

[0052] Step A: using the kilometer drilling rig 1 to drill from the ground to the coal seam to form a vertical borehole 2, continue to turn the drill bit of the kilometer drilling rig 1 to 90° and continue drilling in the coal seam for more than 1000 meters to form the horizontal Drilling 3, cleaning the drill bit of the kilometer drilling rig 1 to remove coal powder;

[0053] Step B: laying the rigid casing in the vertical borehole 2 and the horizontal borehole 3, sealing and sealing the end of the horizontal borehole 3 away from the vertical borehole 2, every two times One hydrothermal cracking cylinder 4 is arranged at a distance of the crack radius;

[0054] Step C: use the kilometer drilling rig 1 to drill from the ground to the centerline of the fissure zone above the coal seam, and turn the drill bit of the kilometer drilling rig 1 to construct the high pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com