A Method for On-line Measurement and Compensation of Surface Position Error of Deep Pipe Inner Wall

A compensation method, the technology of the inner wall of the pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

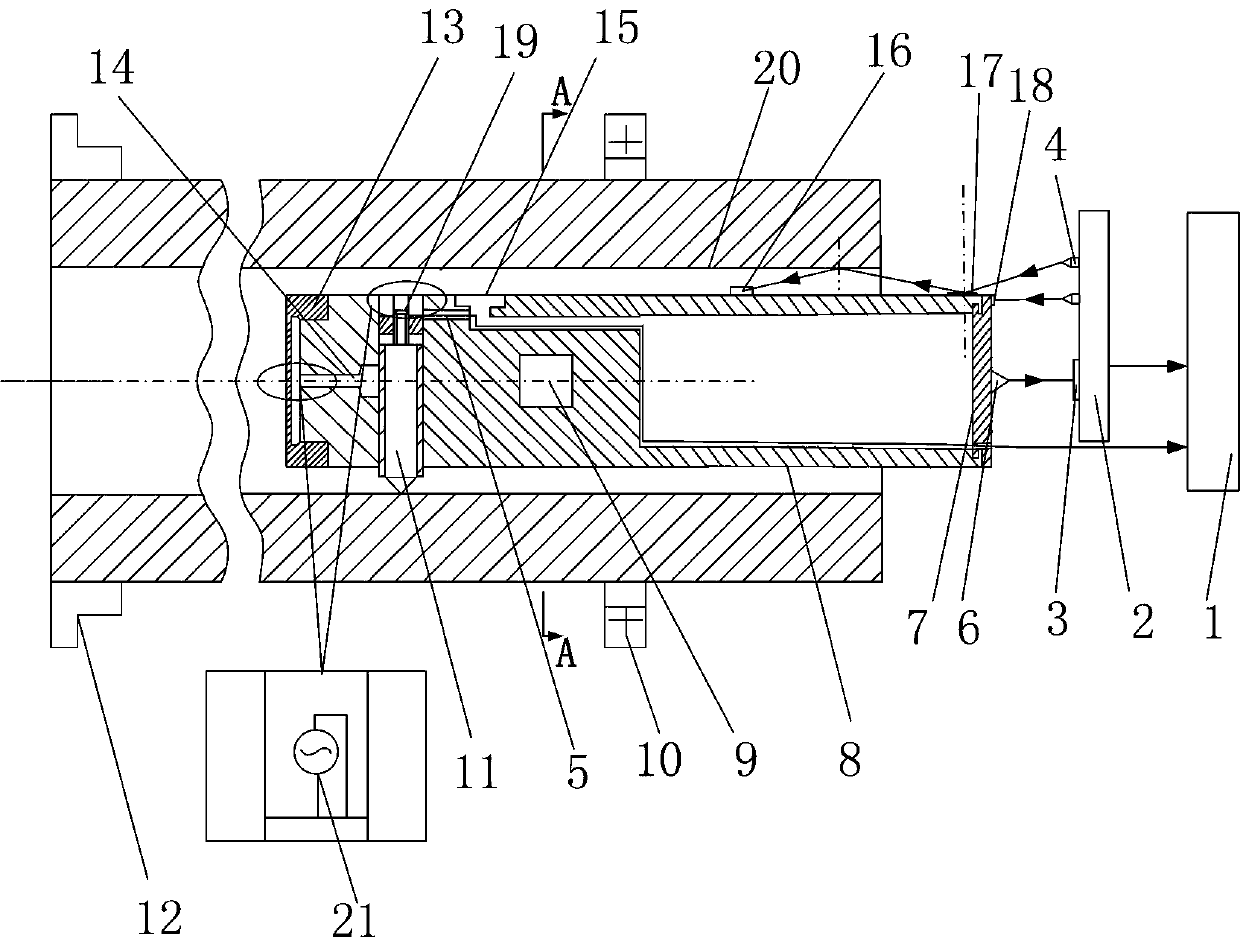

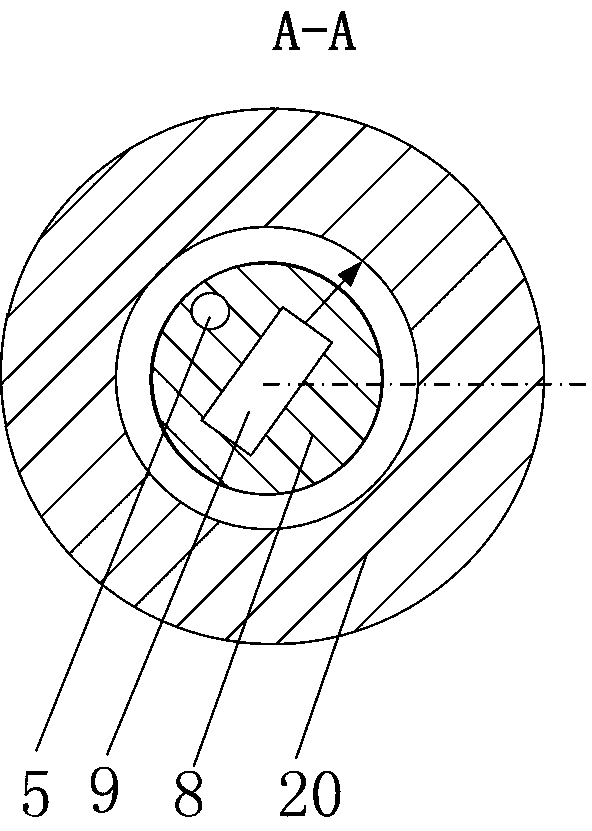

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

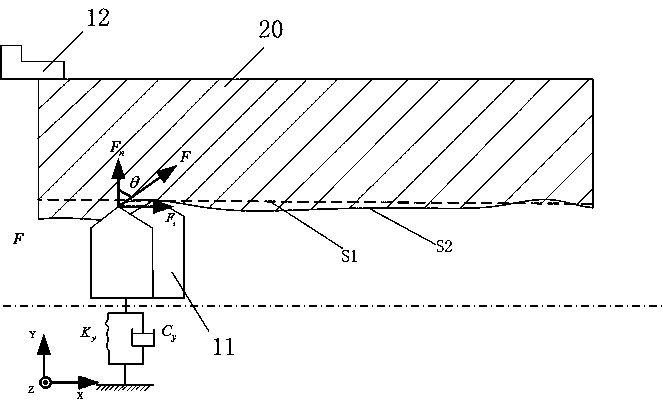

[0041] The present invention needs to perform error value prediction, actual measurement, error evaluation, real-time adjustment and error quantification of the inner wall surface of the deep tube 20 to determine initial processing parameters and complete real-time adjustment during processing. The surface cumulative position error of the inner wall of the deep tube 20 is mainly caused by the forced vibration of the machining process, the overhang of the tool bar 8 and the boring depth, which is expressed as the difference between the ideal machined surface S1 and the actual machined surface S2 of the inner wall of the deep tube 20 , resulting in over-cutting or under-cutting on the inner wall surface of the deep tube 20. With the deepening of the processing and the continuous cutting of the hole wall, the surface position error will show a cumul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com