High-efficiency lasing output dfb semiconductor laser device and photonic integrated emission chip

A laser and semiconductor technology, applied in the field of optoelectronics, can solve problems such as unbalanced laser power, unbalanced output laser power of laser arrays, abnormally complex structure of laser arrays, etc., and achieve the effects of laser self-feedback enhancement, shortened length, and reduced threshold current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

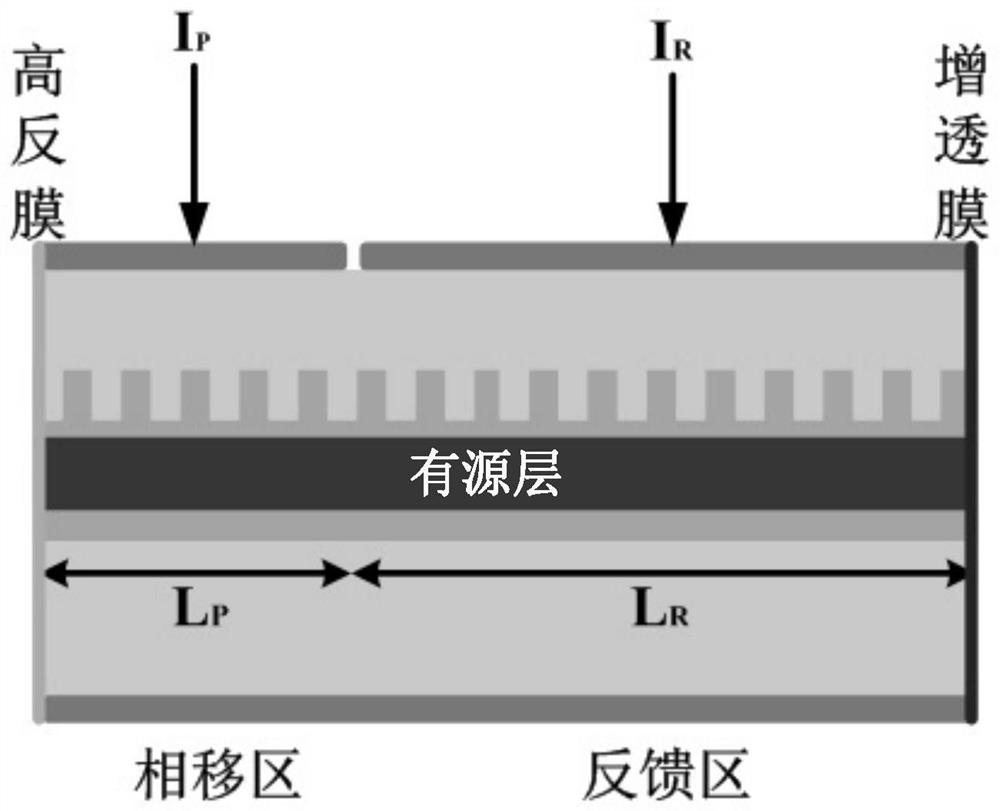

[0026] This embodiment provides a high-efficiency lasing output DFB semiconductor laser device, such as figure 1 As shown, the frequency selection grating is a uniform grating or a uniform sampling grating. The whole laser is divided into two parts: a phase shift area and a feedback area. Other anti-reflection measures.

[0027] In this embodiment: the electrodes in the phase shift region and the feedback region can be electrically isolated by a certain distance, or by implanting helium ions, or by etching an electrical isolation trench.

[0028] The realization principle of the fine adjustment of the lasing wavelength of the high-efficiency lasing output DFB semiconductor laser device of the present invention is as follows:

[0029] we take figure 1 As an example to illustrate, for the sake of simplicity, the lengths of the feedback region and the phase shift region of the laser are respectively L P =L, then when the feedback region and the phase shift region of the lase...

Embodiment 2

[0039] This embodiment provides a distributed feedback semiconductor laser monolithic integrated array, which is composed of the high-efficiency lasing output DFB semiconductor laser device described in the first embodiment.

[0040] This embodiment also provides a photonic integrated emission chip (such as Figure 4 shown), the module consists of a laser monitor array, the above-mentioned distributed feedback semiconductor laser monolithic integrated array, a modulator array, a power equalizer array and a multiplexer, which are sequentially grown and integrated into formed on the same epitaxial wafer.

Embodiment 3

[0042] This embodiment adopts a manufacturing method of a distributed feedback semiconductor laser and an array thereof, the steps of which are as follows:

[0043] (1) Epitaxial n-type InP buffer layer, 100nm thick undoped lattice-matched InGaAsP lower confinement layer, strained InGaAsP multiple quantum wells and 100nm thick p-type lattice-matched InGaAsP upper confinement layer on n-type InP substrate material Floor;

[0044] (2) The production method of the grating:

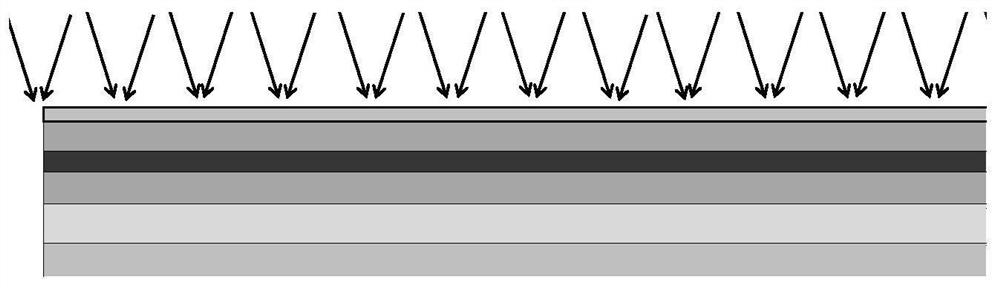

[0045] ① Manufacturing method of uniform grating: use the method of double-beam holographic interference exposure to record the uniform grating pattern on the photoresist on the upper confinement layer, and then apply material etching to form the required uniform grating on the upper part of the upper confinement layer structure. figure 2 It is a schematic diagram of the process of making a uniform grating by double ultraviolet beam interference.

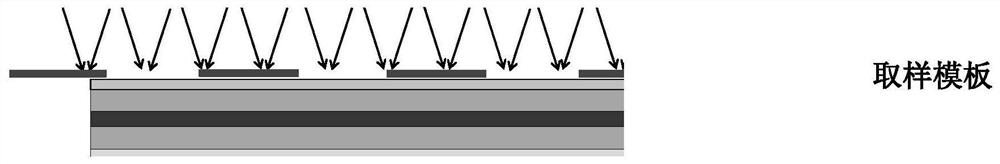

[0046] ②Uniform sampling grating manufacturing method, us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com