Preparation method of N,P-codoped three-dimensional Co nanoflower, obtained material and application

A technology of co-doping and nanoflowers, applied in chemical instruments and methods, electrodes, electrolytic processes, etc., can solve the problems of unsatisfactory catalytic activity and stability, high cost, complicated process, etc., and achieve the suppression of Ostwald Ripening effect, improvement of catalytic activity, and clear mechanism of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

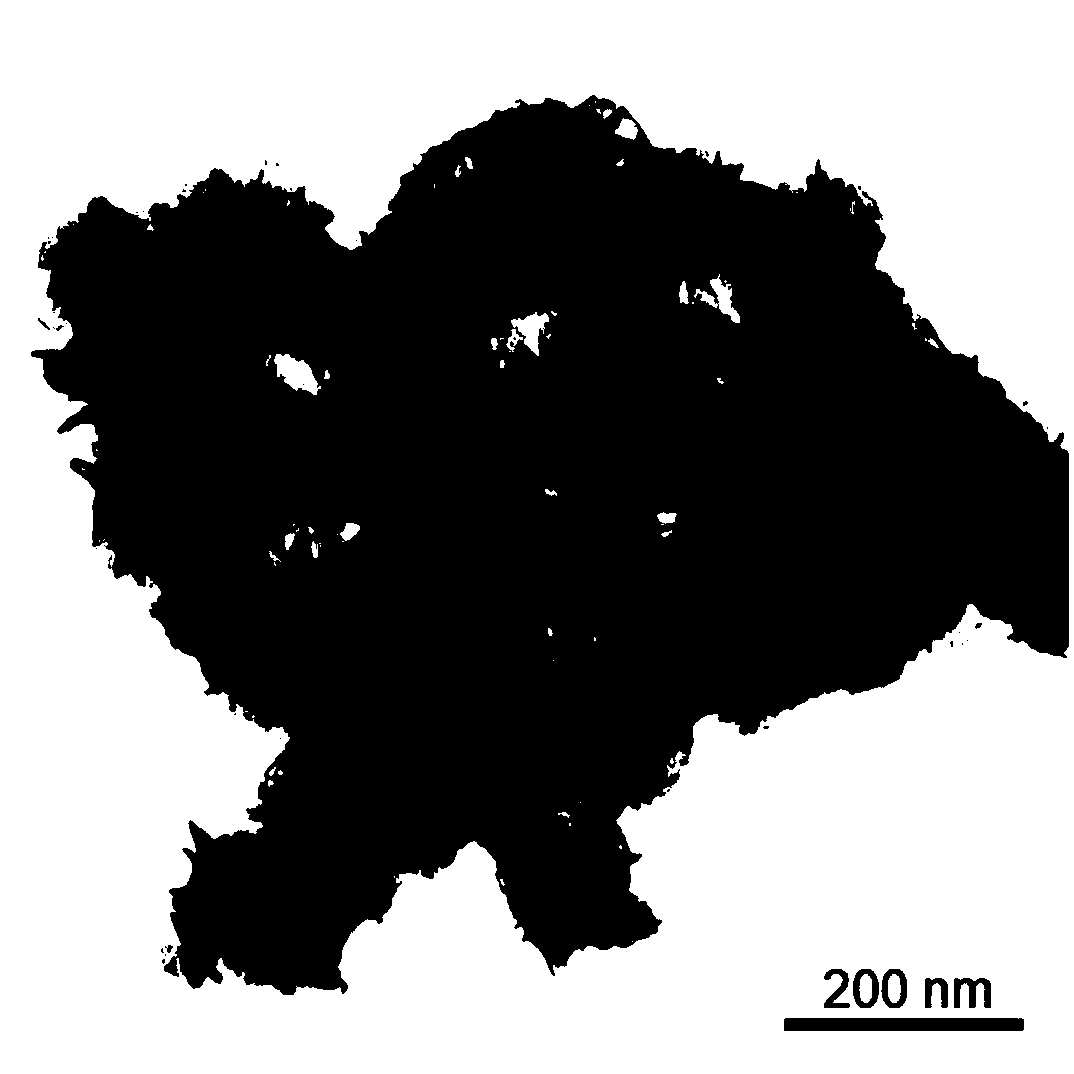

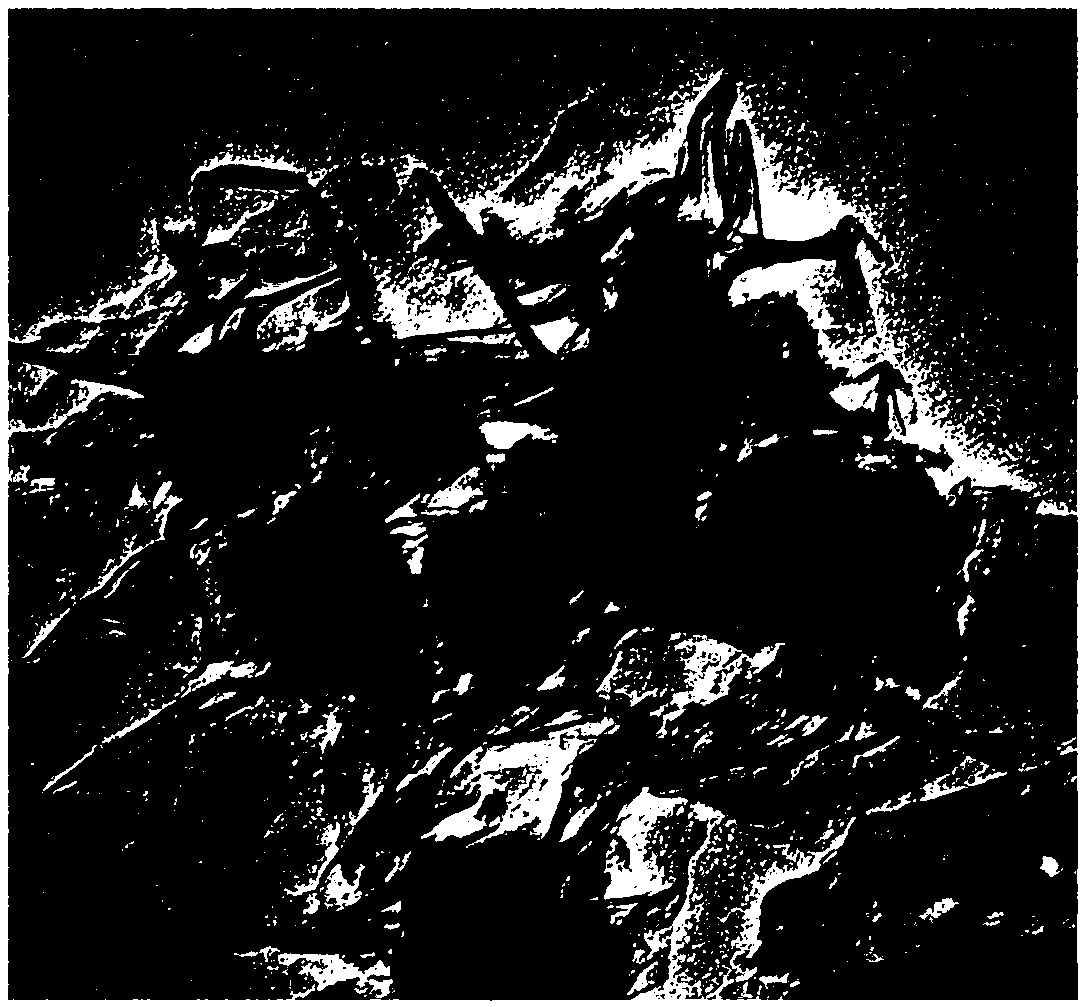

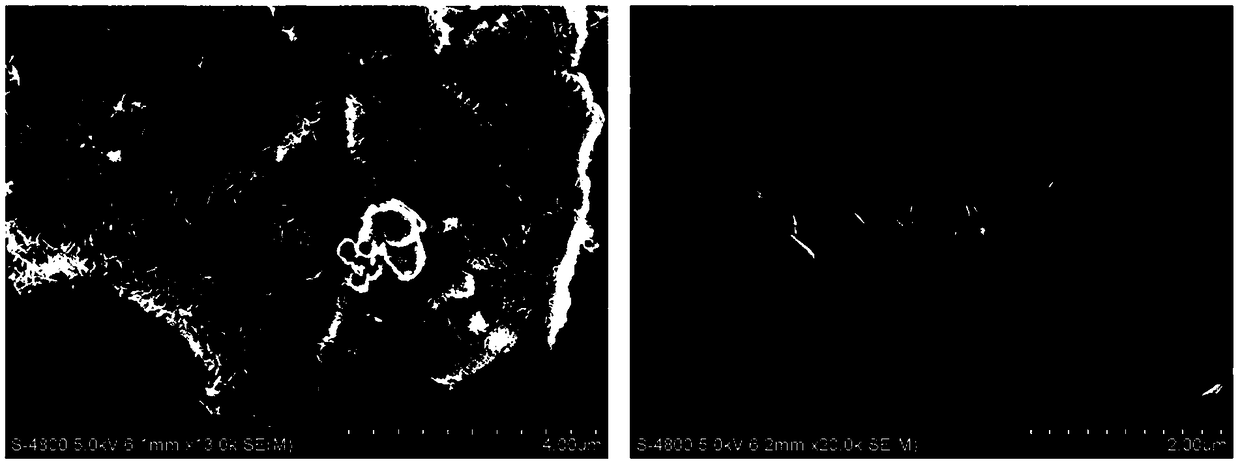

[0032] A preparation method of N, P-co-doped three-dimensional Co nanoflowers, comprising the following steps:

[0033] 1) Recrystallization of precursor and alkali metal inorganic salt saturated solution: Measure 10mL saturated NaCl solution, add 10mL0.05mol L -1 CoCl 2 Precursor solution and 5mL 0.05mol L -1 NaH 2 PO 2 Solution, oscillate to mix evenly, disperse into a watch glass and recrystallize at room temperature.

[0034] 2) Preparation of N,P-co-doped three-dimensional Co nanoflowers: the recrystallized product obtained in step 1) was heated in an ammonia atmosphere at 5°C min -1 The temperature was raised to 600° C. for heat treatment, and kept at this temperature for 3 hours. After cooling to room temperature, the final product was obtained by centrifuging and washing with water for several times.

Embodiment 2

[0036] A preparation method of N, P-co-doped three-dimensional Co nanoflowers, comprising the following steps:

[0037] 1) Recrystallization of precursor and alkali metal inorganic salt saturated solution: measure 10mL saturated Na 2 SO 4 solution, add 10mL0.05mol L -1 CoCl 2 Precursor solution and 5mL 0.05mol L -1 NaH 2 PO 2 Solution, oscillate to mix evenly, disperse into a watch glass and recrystallize at room temperature.

[0038] 2) Preparation of N,P-co-doped three-dimensional Co nanoflowers: the recrystallized product obtained in step 1) was heated in an ammonia atmosphere at 5°C min -1 The temperature was raised to 600° C. for heat treatment, and kept at this temperature for 3 hours. After cooling to room temperature, the final product was obtained by centrifuging and washing with water for several times.

Embodiment 3

[0040] A preparation method of N, P-co-doped three-dimensional Co nanoflowers, comprising the following steps:

[0041] 1) Recrystallization of precursor and alkali metal inorganic salt saturated solution: measure 10mL saturated MgCl 2 solution, add 10mL0.05mol L -1 CoCl 2 Precursor solution and 5mL 0.05mol L -1 NaH 2 PO 2 Solution, oscillate to mix evenly, disperse into a watch glass and recrystallize at room temperature.

[0042] 2) Preparation of N,P-co-doped three-dimensional Co nanoflowers: the recrystallized product obtained in step 1) was heated in an ammonia atmosphere at 5°C min -1 The temperature was raised to 600° C. for heat treatment, and kept at this temperature for 3 hours. After cooling to room temperature, the final product was obtained by centrifuging and washing with water for several times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com