Plastic spraying system and plastic spraying process applying same

A technology of spraying plastic and workpiece, applied in the direction of spraying room, spraying device, liquid spraying device, etc., can solve the problems of increasing labor cost of plastic spraying production line, inconvenient spraying operation, harmful to human body, etc. Plastic operation is convenient and the effect of improving hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

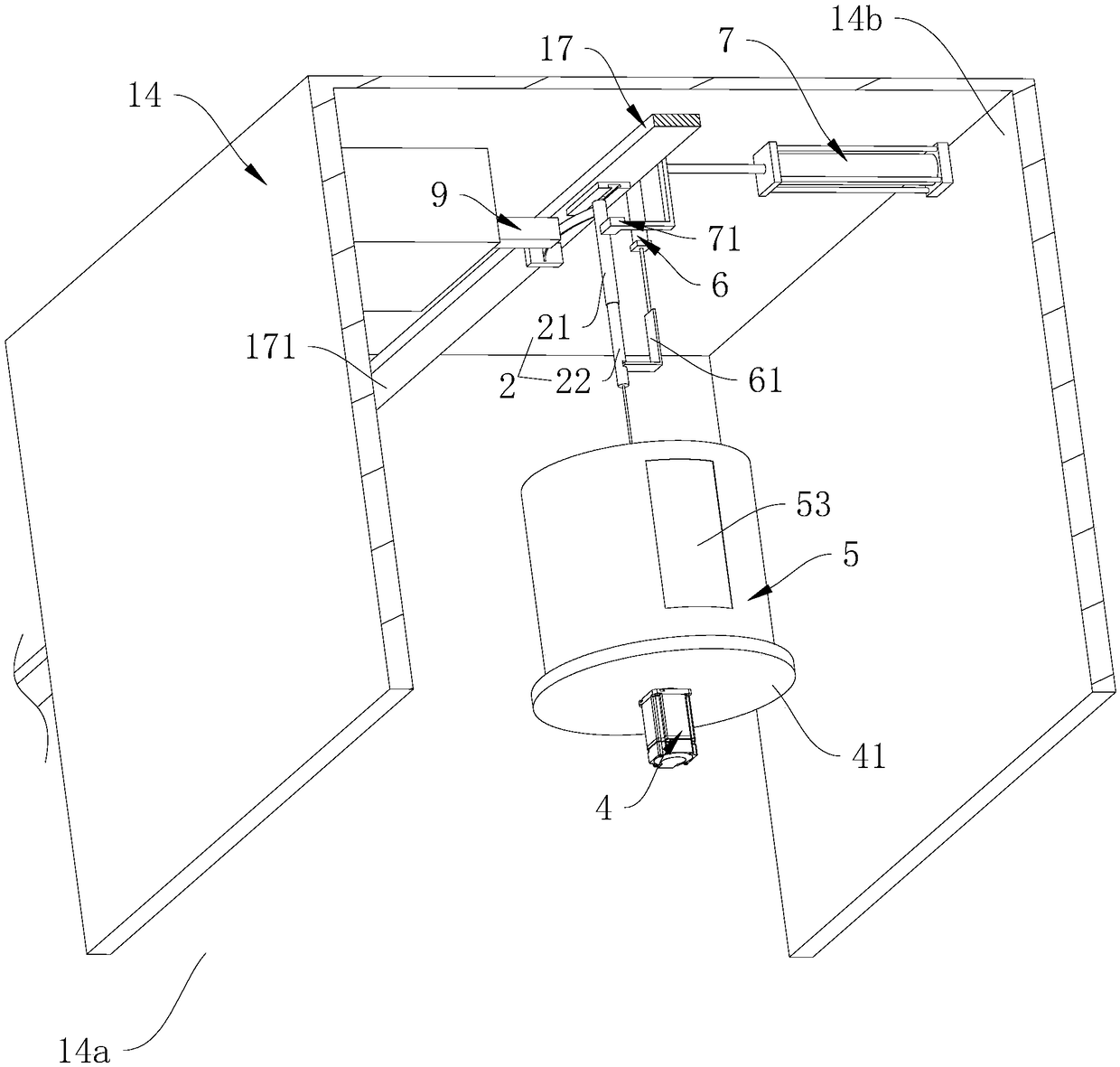

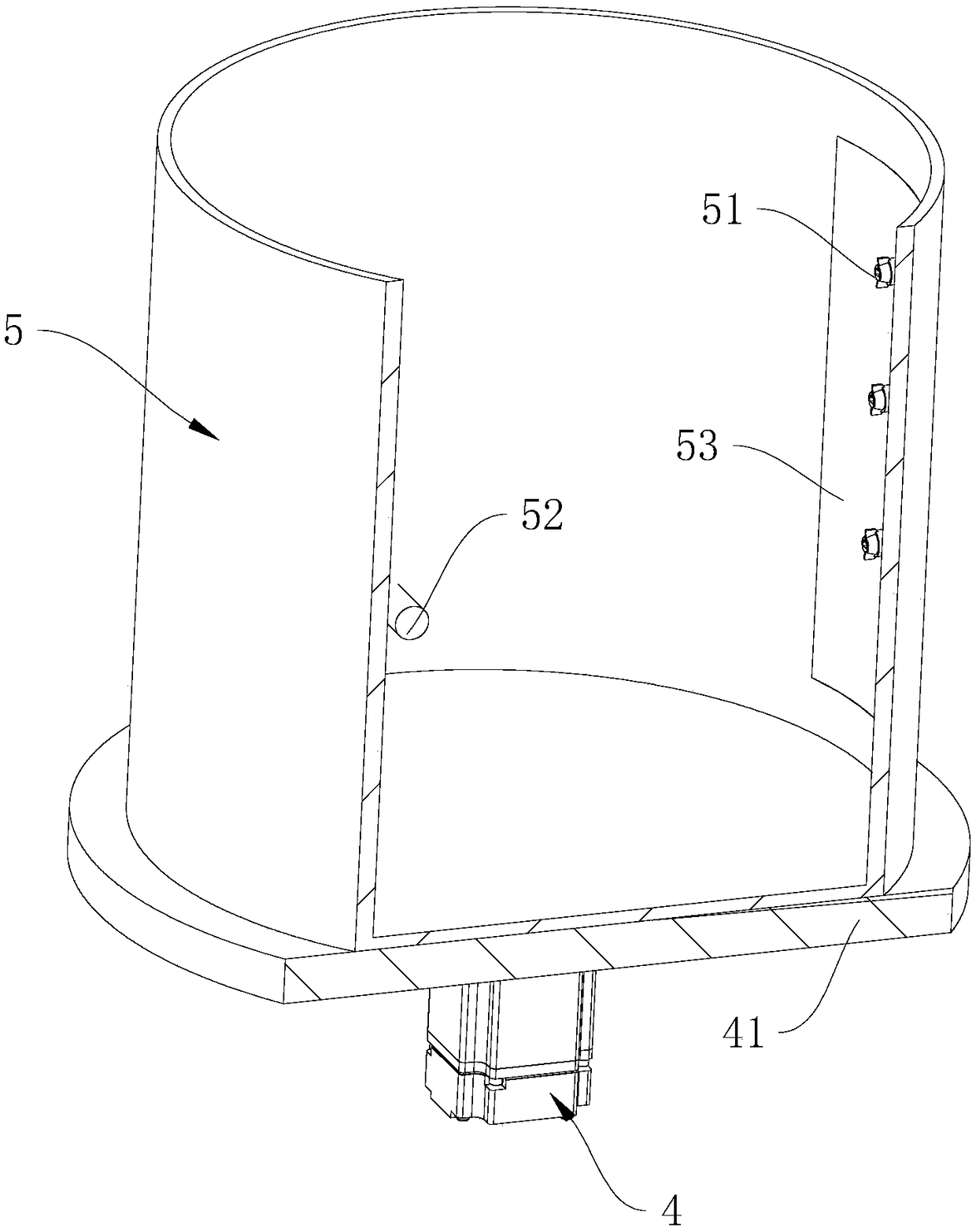

[0033] Such as figure 1 As shown, a plastic spraying system includes a plastic spraying room 14 and a rail conveying line 17, the plastic spraying room 14 has a relative inlet 14a and an outlet 14b, and a plurality of workpieces to be sprayed are hung on the rail conveying line 17, and the guide rail The frame in the conveying line 17 has a transmission chain 171 and a power source (not shown in the figure) that drives the movement of the transmission chain 171. This is the prior art, so it will not be further elaborated in the embodiment of the present invention. 17 runs through the plastic spraying room 14, so that the workpiece to be sprayed enters the plastic spraying room 14 from the inlet 14a, and the plastic sprayed workpiece is transported out from the outlet 14b, realizing the assembly line plastic spraying method.

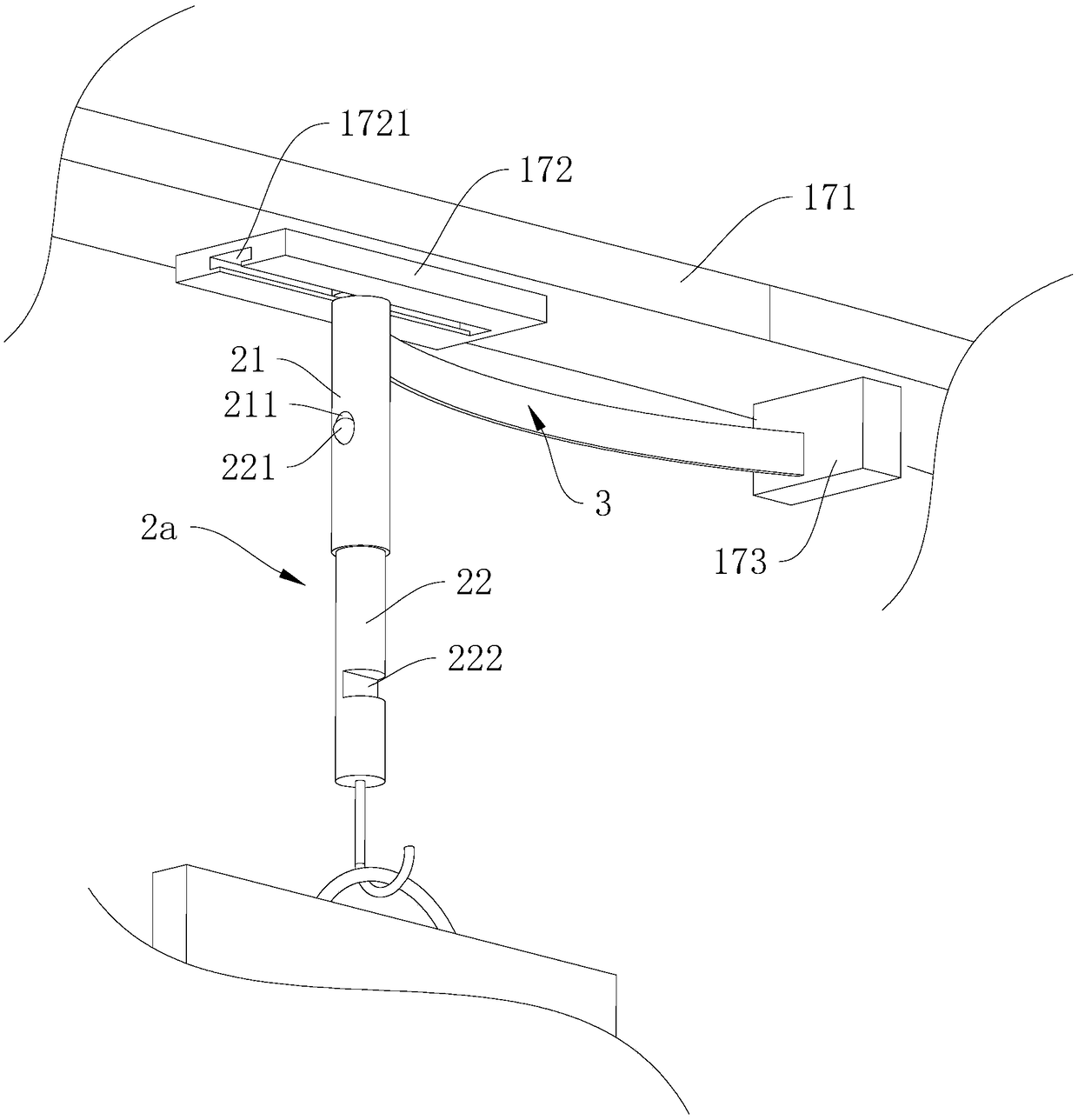

[0034] combine figure 2As shown, on the frame in the guide rail conveying line 17, a plurality of fixed plates 172 are installed below the drive chain ...

Embodiment 2

[0051] combine Figure 5 As shown, a plastic spraying process is applied to the plastic spraying system described in Embodiment 1, and the guide rail conveying line 17 is in the shape of a circular track, and includes the following steps in turn:

[0052] S1. Clamping: hang the workpiece to be sprayed on the loading area 11 to the lower end of the hook 22 in the hanger assembly 2 on the guide rail conveying line 17 .

[0053] S2. Pretreatment: The workpiece to be sprayed is transported to the shower room 12 through the guide rail conveying line 17, and the degreasing and rust removing agent is sprayed in the shower room 12. The formula is 4% oil and rust removing additive XH-16, 60% Hydrochloric acid (35% concentration) and 36% water are used for degreasing and rust removal to improve the adhesion of the coating.

[0054] S3. Preheating: the workpiece to be sprayed after S2 is transferred to the preheating room 13 through the guide rail conveying line 17, and the workpiece to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com