A smooth laser double-sided heat-sealable packaging film for cigarettes and its preparation method

A packaging film and laser technology, applied in the direction of chemical instruments and methods, printing devices, synthetic resin layered products, etc., can solve problems such as difficulty in obtaining cigarette packaging film products, degradation of heat sealing performance, and increase of heat sealing coating, etc., to achieve The heat sealing start temperature is reduced, the stability of the solution performance, and the effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

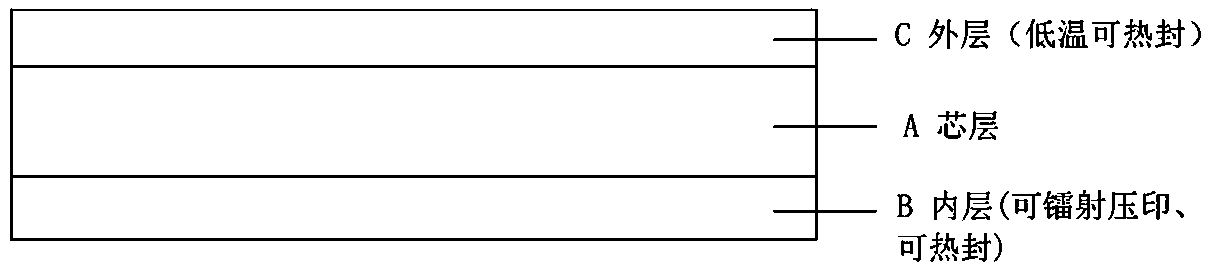

[0026] The preparation method of the glossy laser double-sided heat-sealable cigarette packaging film of the present invention comprises the following steps:

[0027] A. Double-sided heat-sealable laser BOPP substrate film: It is prepared by multi-layer co-extrusion polypropylene biaxial stretching preparation process and polypropylene raw materials. The longitudinal stretching temperature is 70-130 °C, and the transverse stretching temperature is 100~175℃, extruder temperature 200~250℃, draw ratio 4~10;

[0028] B. Laser embossing process: first, surface-treat the inner layer of the double-sided heat-sealable laser BOPP substrate film obtained in step A, and the inner layer treatment intensity is 40-45dyn; then use the laser molding process on the substrate film. Embossing of the laser pattern on the inner layer is enough. The main process of laser molding described above is: electroforming plate making—unwinding—preheating—molding—cooling—rewinding.

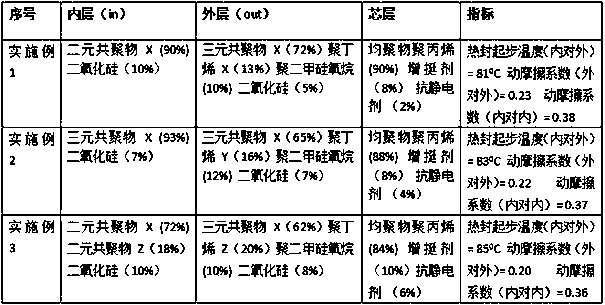

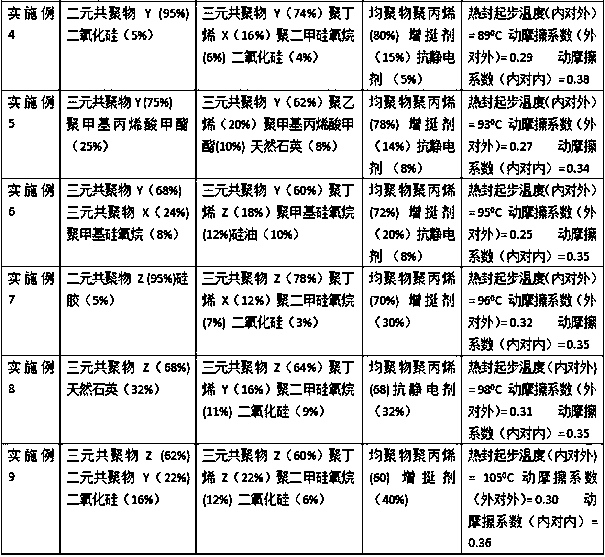

[0029] Examples of do...

Embodiment 10

[0034] Carrying out laser embossing with the laser packaging substrate film obtained in Example 1 to obtain a glossy laser double-sided heat-sealable packaging film for cigarettes, the preparation method comprising the following steps:

[0035] A. Preparation of laser packaging substrate film: It is prepared by multi-layer co-extruded polypropylene biaxial stretching preparation process, wherein the longitudinal stretching temperature is 60°C, the transverse stretching temperature is 100°C, the temperature of the extruder is 200°C, and the stretching temperature is 200°C. Stretch ratio is 4;

[0036] B. Laser embossing processing: processing by laser molding process, the molding temperature is 170°C.

[0037] The water vapor transmission rate of the glossy laser double-sided heat-sealable packaging film for cigarettes prepared in this example is 7 g / m 2 .day, oxygen transmission rate = 1700 cc / m 2 .day; the initial heat-sealing temperature (inside and outside) is 82°C, so th...

Embodiment 11

[0039] The laser packaging substrate film obtained in Example 2 is processed by laser embossing to obtain a smooth laser double-sided heat-sealable packaging film for cigarettes. The preparation method comprises the following steps:

[0040] A. Preparation of laser packaging substrate film: It is prepared by multi-layer co-extrusion polypropylene biaxial stretching preparation process, wherein the longitudinal stretching temperature is 130°C, the transverse stretching temperature is 175°C, and the extruder temperature is 250°C. The draw ratio is 10;

[0041] B. Laser embossing process: first, surface-treat the inner layer of the double-sided heat-sealable laser BOPP substrate film obtained in step A, and the inner layer treatment intensity is 40dyn; then adopt the laser molding process on the inner layer of the substrate film The embossing of the laser pattern can be carried out; the main process of the laser molding is: electroforming plate making-unwinding-preheating-molding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com