Flat shunting mechanical control device with high-accurate positioning

A machine controller, high-precision technology, applied to signal indicators on vehicles, railway car body parts, and transportation center control systems, etc., can solve problems such as low channel utilization, slow data processing speed, and transmission failure. Achieve the effects of improving voice clarity, fast data transmission speed, and improving anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are now described in detail with accompanying drawings as follows. The embodiments described in the accompanying drawings are only used to illustrate the technical solutions of the present invention and are not limiting this invention.

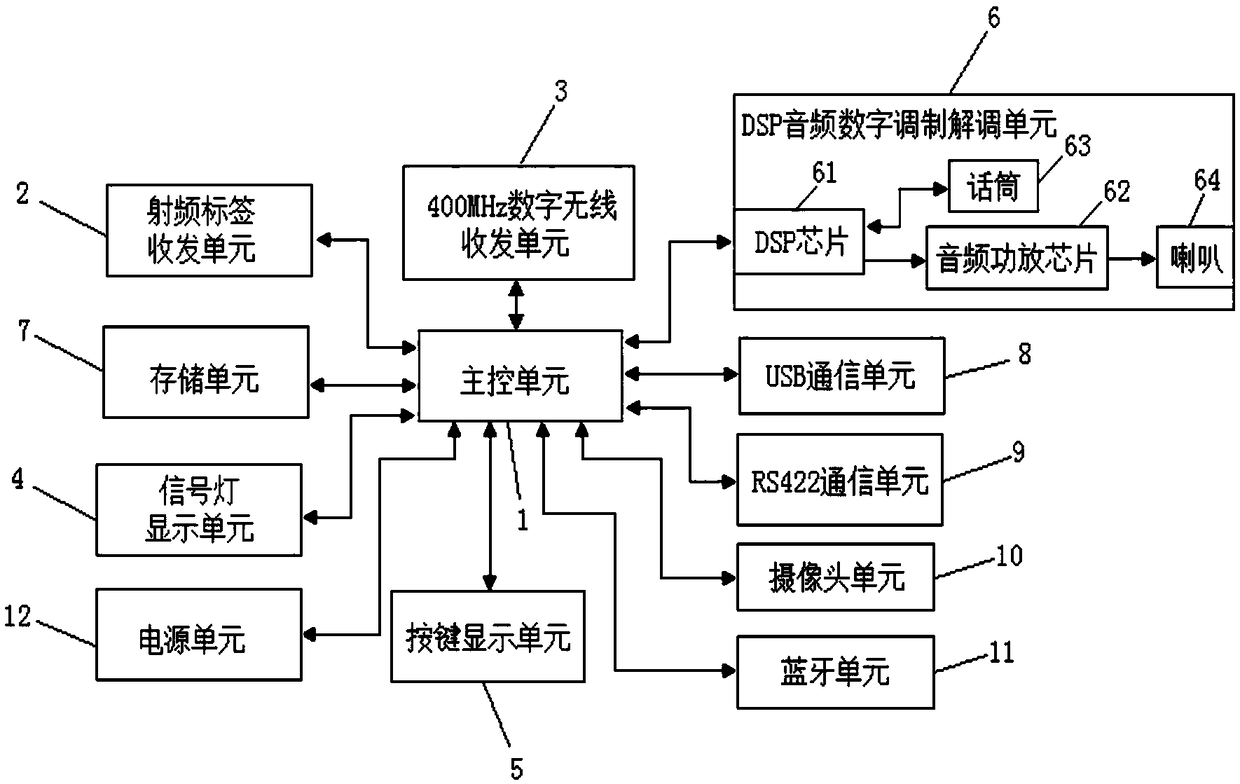

[0027] like figure 1 as shown, figure 1It is a structural schematic diagram of the plane shunting machine controller of the present invention; the plane shunting machine controller supporting high-precision positioning includes a main control unit 1, a radio frequency tag transceiver unit 2, a 400MHz digital wireless transceiver unit 3, and a signal light display unit 4 , key display unit 5, DSP audio digital modulation and demodulation unit 6, storage unit 7, USB communication unit 8, RS422 communication unit 9, camera unit 10, bluetooth unit 11 and power supply unit 12. Main control unit 1 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com