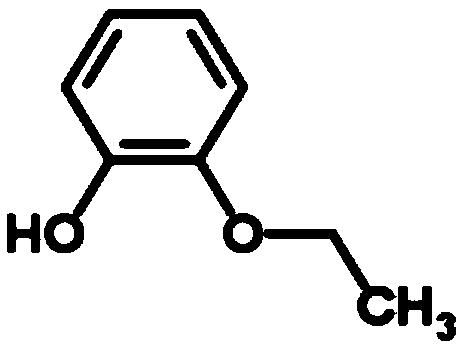

Method for reducing content of volatile phenol in o-ethoxyphenol production wastewater

A technology of o-ethoxyphenol and ethoxyphenol, which is applied in the field of industrial wastewater treatment, can solve the problems of high COD content, poor biochemical treatment effect, high volatile phenol content, etc., and achieve high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 of the present invention: a method for reducing volatile phenol content in o-ethoxyphenol production wastewater, comprising the following steps:

[0016] S100: aerating the o-ethoxyphenol production wastewater through an aeration device;

[0017] S200: adding sulfuric acid solution to the waste water from the production of o-ethoxyphenol to adjust the pH value to 2; in the step S200, the concentration of the sulfuric acid solution is 50%, and the micro-aeration time is 10 hours. Its purpose is to precipitate tar, which can only be precipitated in a large amount in an acidic environment; the purpose of aeration is to mix evenly. Removing tar also achieves the effect of reducing COD and volatile phenols.

[0018] S300: Adjust the aeration valve of the aeration device, and perform micro-aeration for 8 hours; wherein, the functions of step S200 and step S300 are to remove tar on the surface, mainly substances with higher boiling points. The main purpose is to...

Embodiment 2

[0024] Embodiment 2: a kind of method that reduces volatile phenol content in the production waste water of o-ethoxyphenol, comprises the following steps:

[0025] S100: aerating the o-ethoxyphenol production wastewater through an aeration device;

[0026] S200: adding sulfuric acid solution to the waste water from o-ethoxyphenol production to adjust the pH value to 4; the concentration of the sulfuric acid solution in the step S200 is 50%, and the micro-aeration time is 10 hours.

[0027] S300: Adjust the aeration valve of the aeration device, and perform micro-aeration for 10 hours; wherein, the function of step S200 and step S300 is to remove tar on the surface, mainly substances with higher boiling points. The main purpose is to remove tar, which otherwise affects the post-processing effect.

[0028] S400: Add 1% oxidant by weight to the o-ethoxyphenol production wastewater; add sulfuric acid solution to the o-ethoxyphenol production wastewater to adjust the pH value to 4...

Embodiment 3

[0033] Embodiment 3: a kind of method that reduces volatile phenol content in the production waste water of o-ethoxyphenol, comprises the following steps:

[0034] S100: aerating the o-ethoxyphenol production wastewater through an aeration device;

[0035] S200: adding sulfuric acid solution to the waste water from o-ethoxyphenol production to adjust the pH value to 3; in the step S200, the concentration of the sulfuric acid solution is 50%, and the micro-aeration time is 10 hours.

[0036] S300: Adjust the aeration valve of the aeration device, and perform micro-aeration for 9 hours; wherein, the function of step S200 and step S300 is to remove tar on the surface, mainly substances with higher boiling points. The main purpose is to remove tar, which otherwise affects the post-processing effect.

[0037] S400: Add 0.7% oxidant by weight to the o-ethoxyphenol production wastewater; add sulfuric acid solution to the o-ethoxyphenol production wastewater to adjust the pH value to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com