Method for building PPy (polypyrrole) thin film with multiple forms based on silicon template

A technology of polypyrrole and template, applied in the direction of coating, etc., can solve the problems of limiting the application range and increasing the specific surface area of PPy film, and achieve the effect of good repeatability, avoiding complicated preparation process and avoiding operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: a kind of method for building polypyrrole film with multi-level morphology based on silicon template, comprises the following steps:

[0020] Step 1: Mix the PDMS prepolymer and crosslinking agent according to the mass ratio of 10:1, pour it into a centrifuge tube, and stir with a glass rod to form a uniform mixture;

[0021] Step 2: vacuum degas the mixture of PDMS prepolymer and cross-linking agent for 1 hour, pour it into a square container with a silicon template, and distribute it evenly in the petri dish;

[0022] Step 3: Vacuum degas the mixture of prepolymer and crosslinking agent poured into the petri dish for 30 minutes, then put it in an oven, heat and cure at 70°C for 4 hours, and obtain a PDMS stamp with a silicon template pattern;

[0023] Step 4: Dissolving 0.2013g of pyrrole monomer in 30ml of hydrochloric acid, then dissolving 0.9732g of ferric chloride in 30ml of hydrochloric acid, and ultrasonically mixing;

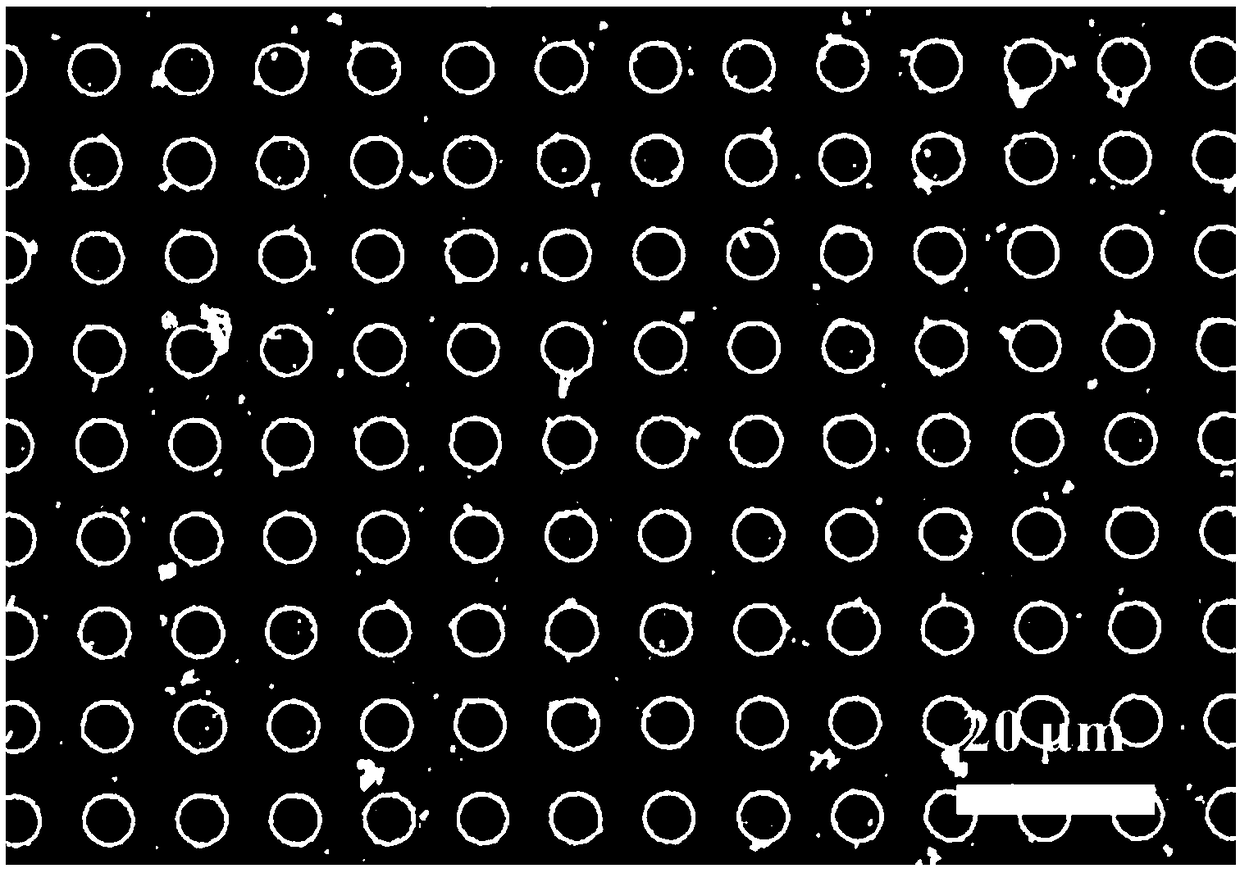

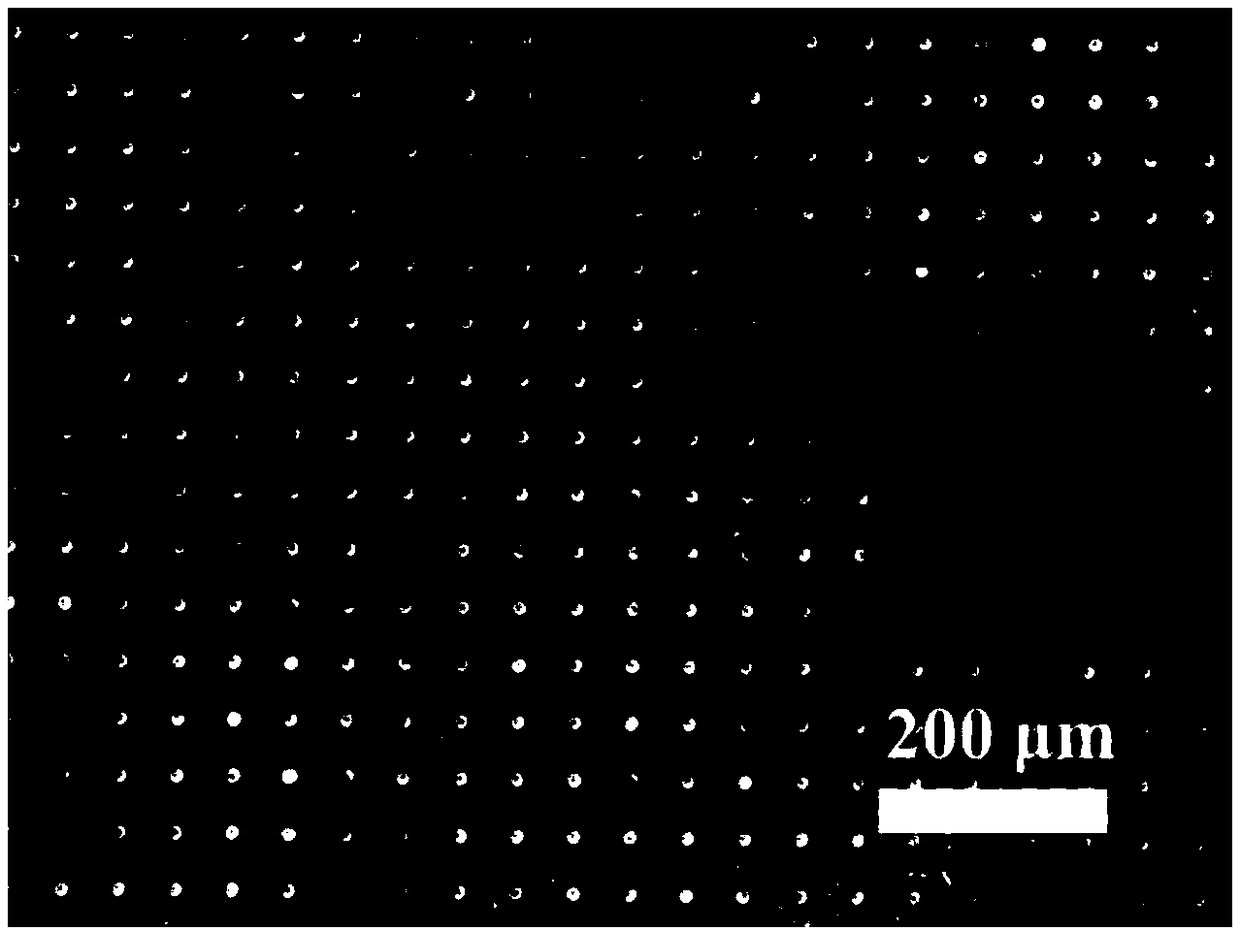

[0024] Step 5: First transf...

Embodiment 2

[0026] Embodiment 2: a kind of method that builds the polypyrrole thin film with multilevel morphology based on silicon template, in embodiment 2, except that step five is different from the step in embodiment 1, other steps are all the same. In step five, the reaction time is adjusted from 3h to 7h, and the obtained polypyrrole film material is as follows image 3 and Figure 4 shown.

[0027] The invention deposits a PPy film on a PDMS stamp by using a template replication method to obtain a PPy film with a multi-level wrinkle structure. PPy films with different surface morphologies can be obtained by adjusting different reaction times. The longer the reaction time, the larger the wrinkle period obtained. The method of the invention overcomes the previous shortcomings of complicated preparation process and poor process controllability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com