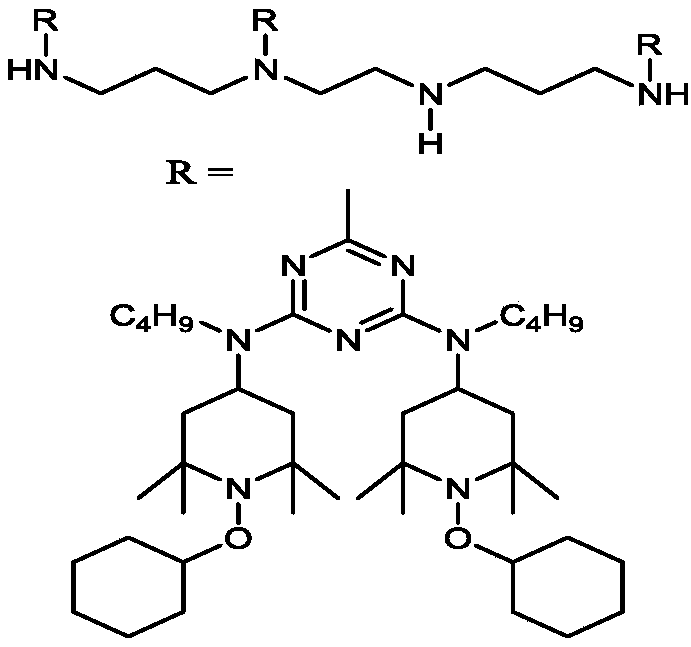

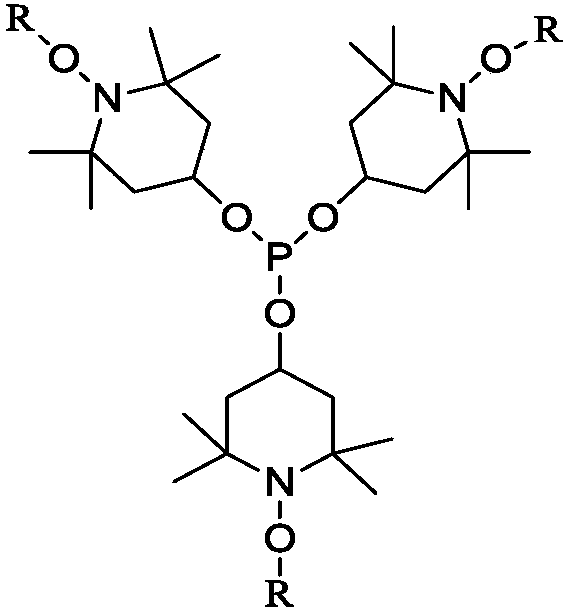

Flame retardant polypropylene material with good light stability and preparation method thereof

A technology of flame-retardant polypropylene and light stability, which is applied in the field of flame-retardant polypropylene materials and their preparation, and flame-retardant polypropylene materials, can solve the problems of poor light stability of flame-retardant PP, and achieve good light stability, The effect of good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

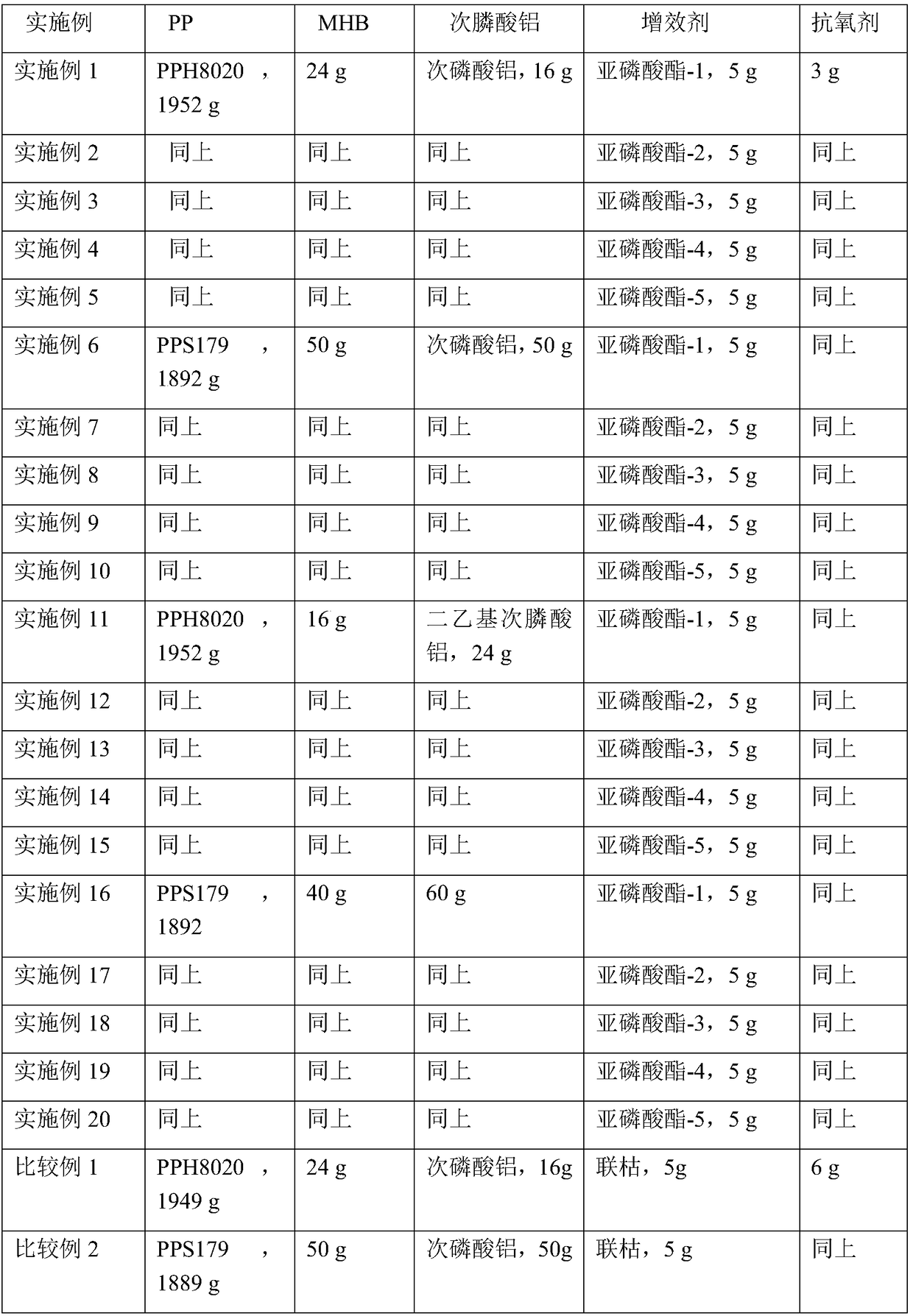

[0032] A flame-retardant polypropylene material with good light stability and a preparation method thereof, the composition and the quality of each component are listed in Table 1:

[0033] Its preparation method is as follows: accurately weigh the quality of each component, first add MHB, inorganic aluminum hypophosphite, phosphite-1 and antioxidant into a grinding mixer (Tianjin Test Co., Ltd.) and mix for 3 minutes, and then pour it into the mixture. into a 5L mechanical mixer, add PP particles and mix for 3min, and finally pass the above mixture through a twin-screw extruder (JS30A twin-screw extruder produced by Yantai Qitong Powder Machinery Co., Ltd., L / D=42.5cm / 2cm , rotational speed 20-30rpm, extrusion temperature 190-200℃) melt-kneading, extrusion, granulation and drying to obtain flame retardant PP material with good light stability.

[0034] The main mechanical properties and flame retardant properties of the flame retardant PP prepared by the above composition and...

Embodiment 2~ Embodiment 20

[0037] The compositions of Examples 2 to 20 and the mass of each component are listed in Table 1. The preparation method is the same as that of Example 1, and the main mechanical properties and flame retardant properties are listed in Table 2. The data in Table 2 shows that the flame retardant PP prepared according to Examples 2 to 20 has almost the same characteristics as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com