Nano-functional finishing agent and preparation method thereof

A functional and finishing agent technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of single function and low safety, and achieve the effect of improving antibacterial properties and increasing photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

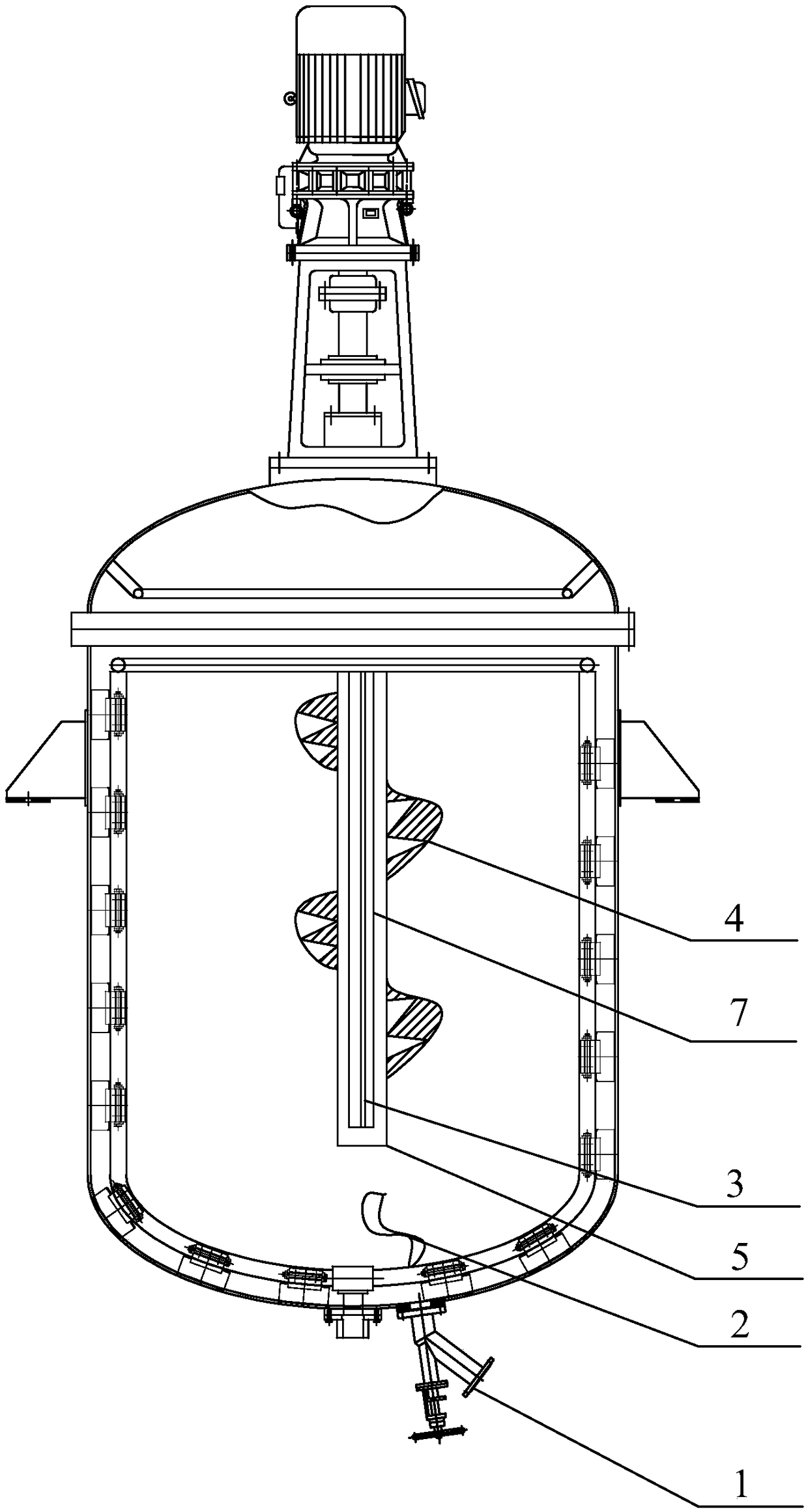

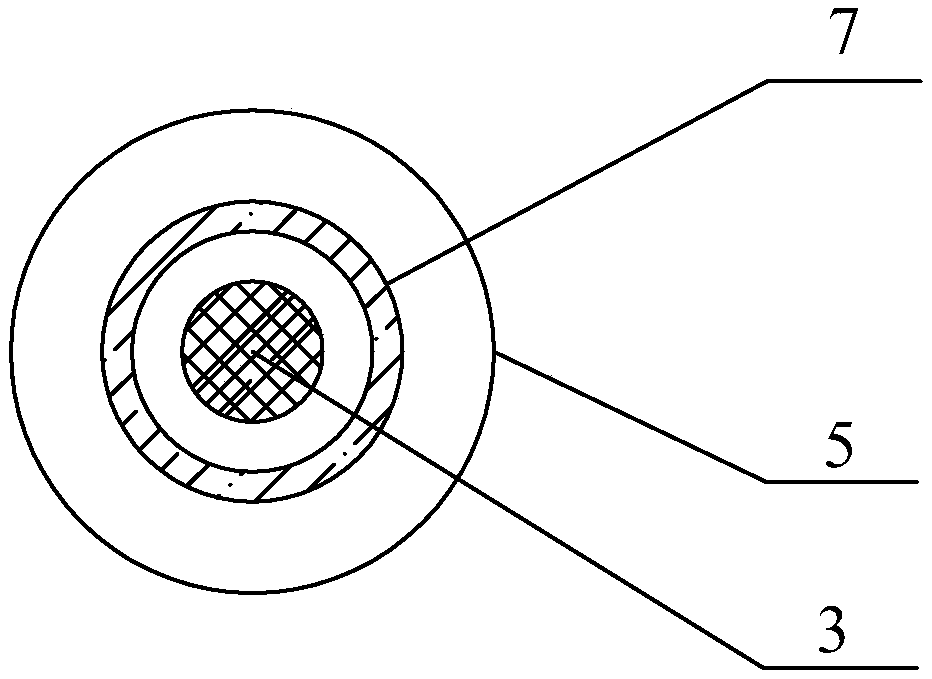

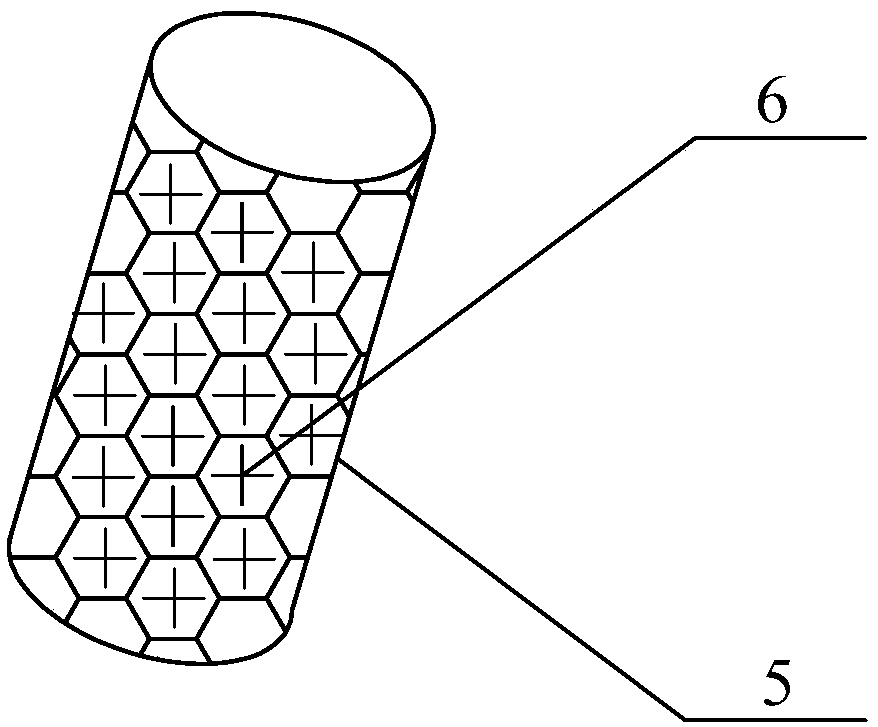

Embodiment 1

[0034] (1) 500Kg of nano-TiO with an average particle size of 50nm 2 Add the ethanol dispersion into the still body of the above-mentioned reaction kettle, and then 100Kg particle diameter is the nano g-C of 10nm 3 N 4 Added to the jet feeding device, sprayed into the nano-TiO 2 In the dispersion liquid, when spraying, the trajectory of the nozzle should be in a spiral shape with a diameter of 200mm. The method of pressing a circle into a semicircle moves slowly and evenly, and then stirs evenly at room temperature to obtain nano-TiO 2 / g -C 3 N 4 Composite dispersion;

[0035] (2) Then in nano TiO 2 / g -C 3 N 4 In the composite dispersion liquid, add 50Kg far-infrared ceramic powder (40wt% SiO 2 , 50wt% Al 2 o 3 and 10wt% AgCl), stirred at 100°C for 60min to obtain a mixed solution;

[0036] (3) When the mixed solution obtained in step (2) is cooled to room temperature, 200Kg fatty alcohol polyoxyethylene ether is added in the feeding sleeve, and the stirring devic...

Embodiment 2

[0038] (1) 1000Kg of nano-TiO with a particle size of 100nm 2 The ethanol dispersion liquid is added into the still body of above-mentioned reactor, then 200Kg particle diameter is the nanometer g-C of 25nm 3 N 4 Added to the jet feeding device, sprayed into the nano-TiO 2 In the dispersion liquid, when spraying, the trajectory of the nozzle should be in a spiral shape, with a diameter of 300mm. The method of pressing a circle into a semicircle moves evenly and slowly, and then stirs evenly at room temperature to obtain nano-TiO 2 / g -C 3 N 4 Composite dispersion;

[0039] (2) Then in nano TiO 2 / g -C 3 N 4 In the composite dispersion liquid, add 100Kg far-infrared ceramic powder (40wt% SiO 2 , 20wt% CaO, 30wt% ZrO 2 and 10wt% AgCl), stirred at 150°C for 30min to obtain a mixed solution;

[0040] (3) When the mixed solution obtained in step (2) is cooled to room temperature, 400Kg fatty alcohol polyoxyethylene ether is added in the feeding sleeve, and the stirring de...

Embodiment 3

[0042] (1) 800Kg of nano-TiO with a particle size of 80nm 2 The ethanol dispersion liquid is added into the still body of above-mentioned reactor, then 150Kg particle diameter is the nano g-C of 20nm 3 N 4 Added to the jet feeding device, sprayed into the nano-TiO 2 In the dispersion liquid, when spraying, the trajectory of the nozzle should be in a spiral shape, with a diameter of 250mm, and the method of pressing a circle into a semicircle will move evenly and slowly, and then stir evenly at room temperature to obtain nano-TiO 2 / g -C 3 N 4 Composite dispersion;

[0043] (2) Then in nano TiO 2 / g -C 3 N 4 In the composite dispersion liquid, add 80Kg far-infrared ceramic powder (40wt% SiO 2 , 50wt% ZrO 2 and 10wt% AgCl), stirred at 120°C for 50min to obtain a mixed solution;

[0044] (3) After the mixed solution obtained in step (2) is cooled to room temperature, 300Kg fatty alcohol polyoxyethylene ether and 8000Kg water are added in the feeding sleeve, and the stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com