Tunnel vault second lining concrete vacuum auxiliary pouring method

A vacuum-assisted pouring method technology, which is applied in tunnel lining, tunnel, earthwork drilling and mining, etc., can solve problems such as the decline in the structural bearing capacity of the vault, the separation of the secondary lining concrete from the vault, etc., to meet the design intention and improve Concrete thickness and lining strength, effect of improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

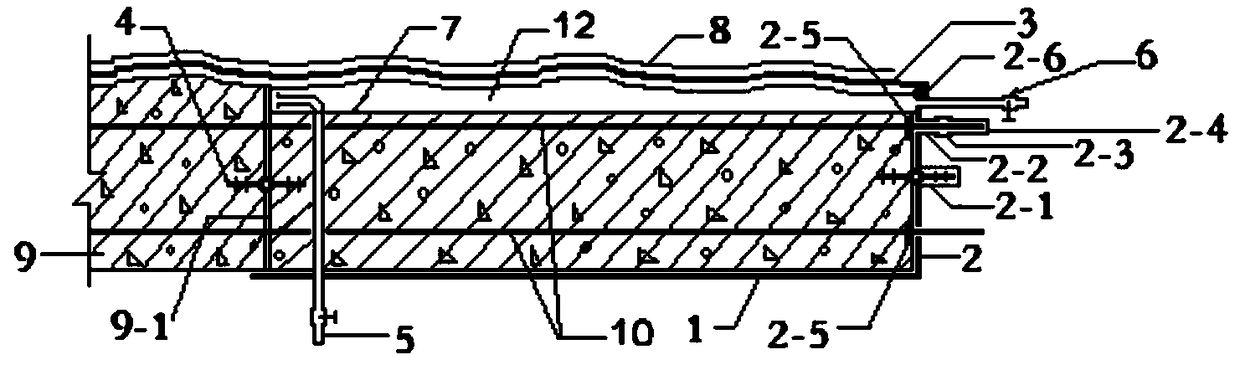

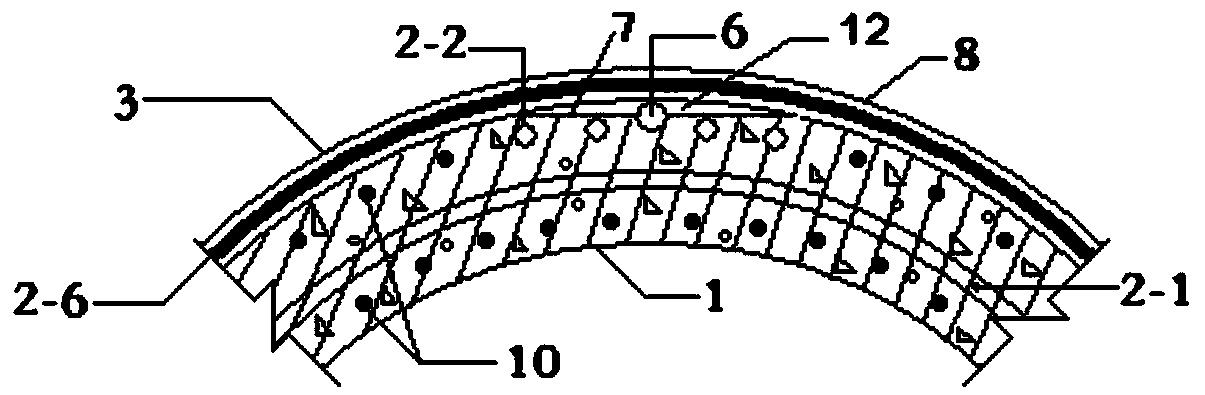

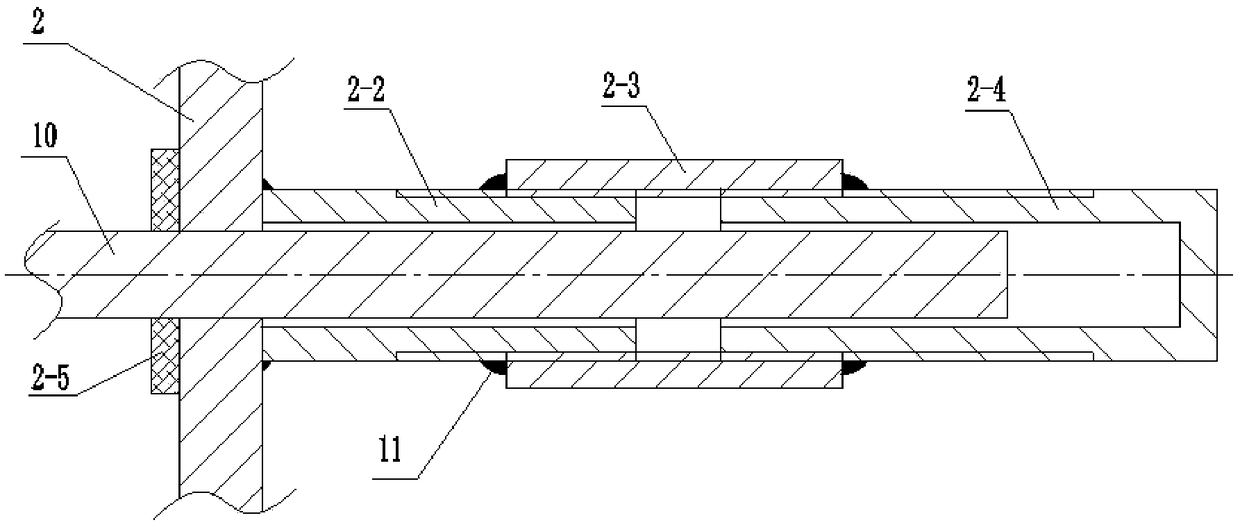

[0047] Further, see figure 1 , 3 , as a specific embodiment of the vacuum-assisted pouring method for tunnel vault second-lined concrete provided by the present invention, the two ends of the connecting pipe 2-3 are connected to the first casing 2-2 and the second casing The joints of 2-4 are coated with sealant. The casing sealant further seals the reserved holes for installing the main ribs of the vault on the end formwork to further ensure the sealing effect.

[0048] Please refer to figure 1 and figure 2 , the specific construction steps are as follows:

[0049] 1. Put the lining trolley in place, and when in place, the vault formwork overlaps with the completed vault second lining by 30cm;

[0050] 2. Install the end formwork, penetrate the main reinforcement of the lap joint into the rubber gasket and protrude out of the end formwork, the outer end of the main reinforcement of the upper vault is sealed and connected with the connecting pipe with the first sleeve an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com