A high-strength aging-resistant high-pulse flame-retardant hydraulic hose and its preparation method

An aging-resistant, high-pulse technology, used in pipes, hoses, mechanical equipment, etc., can solve the problems of increasing the number of pulses, reducing permanent deformation during use, and achieving good fatigue resistance, good aging resistance, corrosion resistance, and good process performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

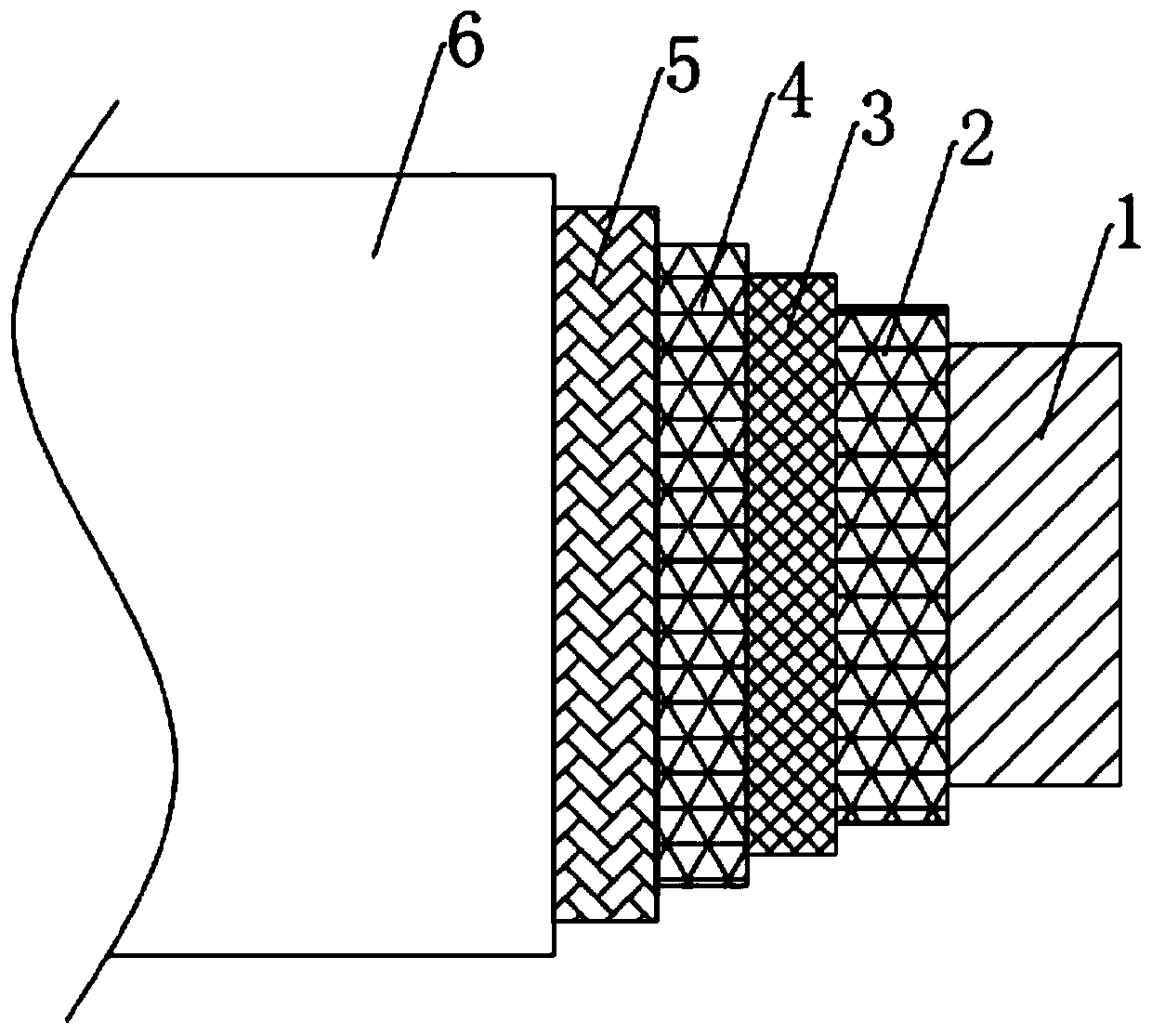

[0062] Such as figure 1 The high-strength, aging-resistant, high-pulse, and flame-retardant hydraulic hose shown includes an inner rubber layer 1, a first glass fiber layer 2, a steel wire winding reinforcement layer 3, a second glass fiber layer 4, and a steel wire braided layer arranged sequentially from the inside to the outside. For the reinforcement layer 5 and the outer rubber layer 6, the winding directions of the first glass fiber layer 2 and the second glass fiber layer 4 are opposite.

[0063] Wherein, in order to improve the strength of the steel wire wound reinforcement layer 3, the steel wire wound reinforcement layer 3 includes 1-4 layers of wound steel wires, and the winding directions of each layer of wound steel wires are opposite. That is, when the first layer is wound clockwise, it is wound counterclockwise with its adjacent layer, maintaining the reverse winding of the adjacent layer.

[0064] In addition, in order to improve the corrosion resistance, impa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com