Cleaning system and method for cement production line kiln tail smoke chamber discharging slope crust

A production line and skinning technology, applied in the combustion method, combustion product treatment, removal of solid residues, etc., can solve the problems affecting the continuous operation of the production line, blockage, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

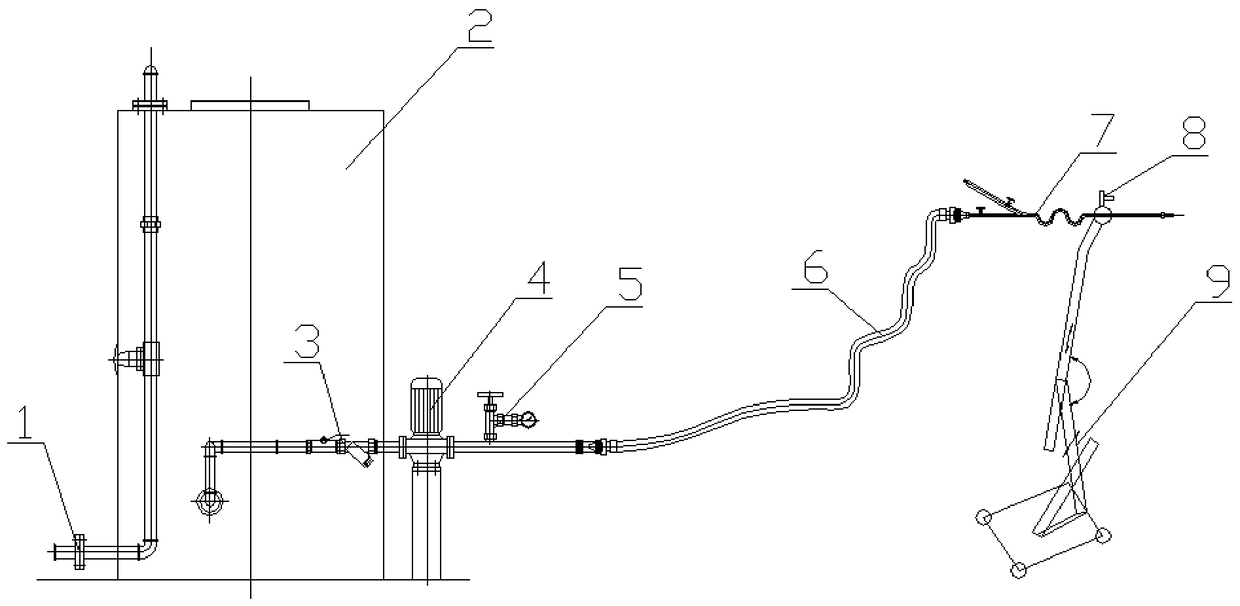

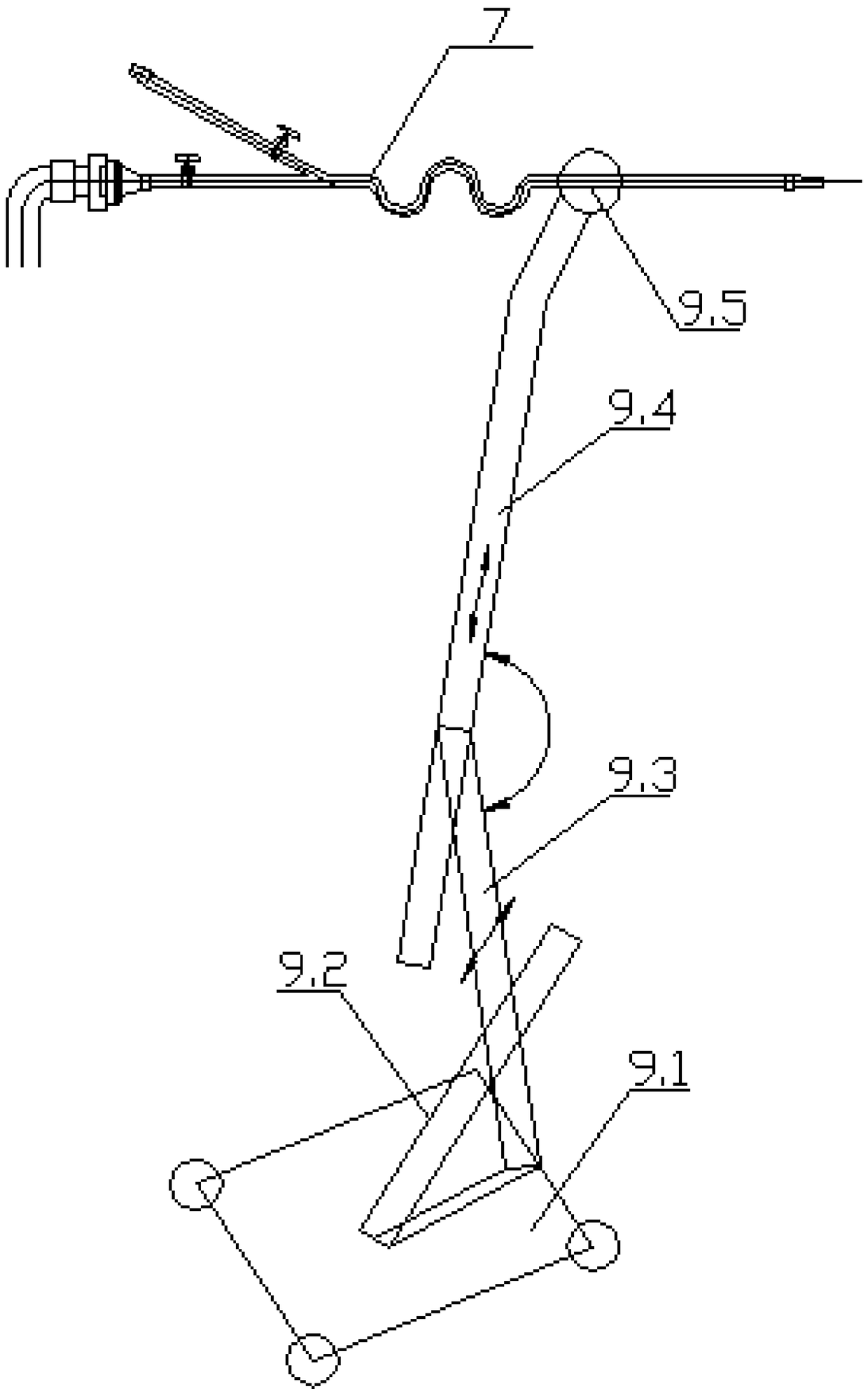

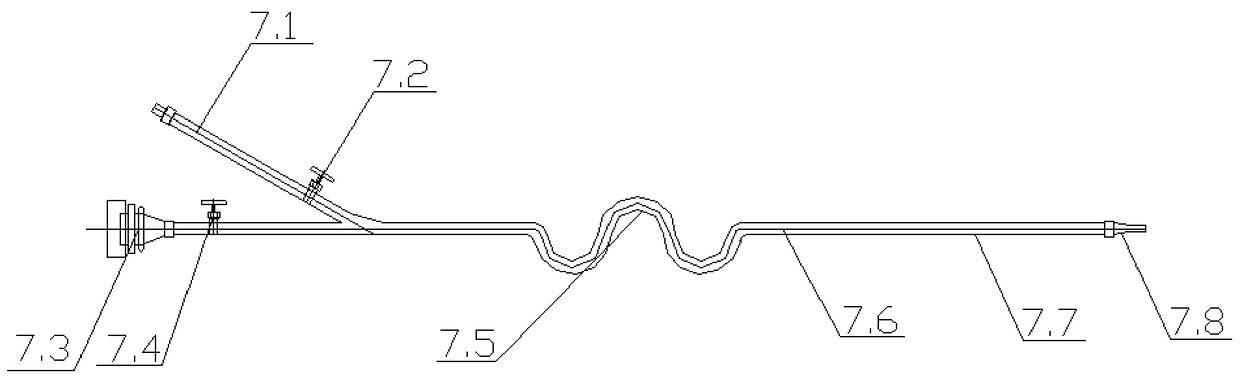

[0023] like figure 1 , 2 , 3, the cement production line kiln tail smoke chamber blanking slope crust cleaning system, which includes a water tank 2, a high-pressure water pump 4, a high-pressure spray gun 7, a high-temperature camera 8, a mobile car 9, an infrared scanner 10 and a control box 11 , the water inlet of the water tank is connected to the fire water system through the water inlet pipe, the water inlet valve 1 is arranged on the water inlet pipe, the water outlet of the water tank is connected to the high-pressure water pump 4 through the water outlet pipe, the water outlet valve 3 is arranged on the water outlet pipe, and the water outlet pipe of the high-pressure water pump An electric valve 5 is provided, and the outlet pipe is connected to the high-pressure spray gun 7 through the hose 6. The hose can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com