Sensitivity-enhanced quasi-distributed optical fiber pressure sensor

A pressure sensor and quasi-distribution technology, applied in the direction of fluid pressure measurement, measurement of fluid pressure, instruments, etc. using optical methods, can solve the problems of large temperature influence, high production cost and precision requirements, high humidity and cleanliness requirements, etc. Achieve flexible geometry, low cost and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

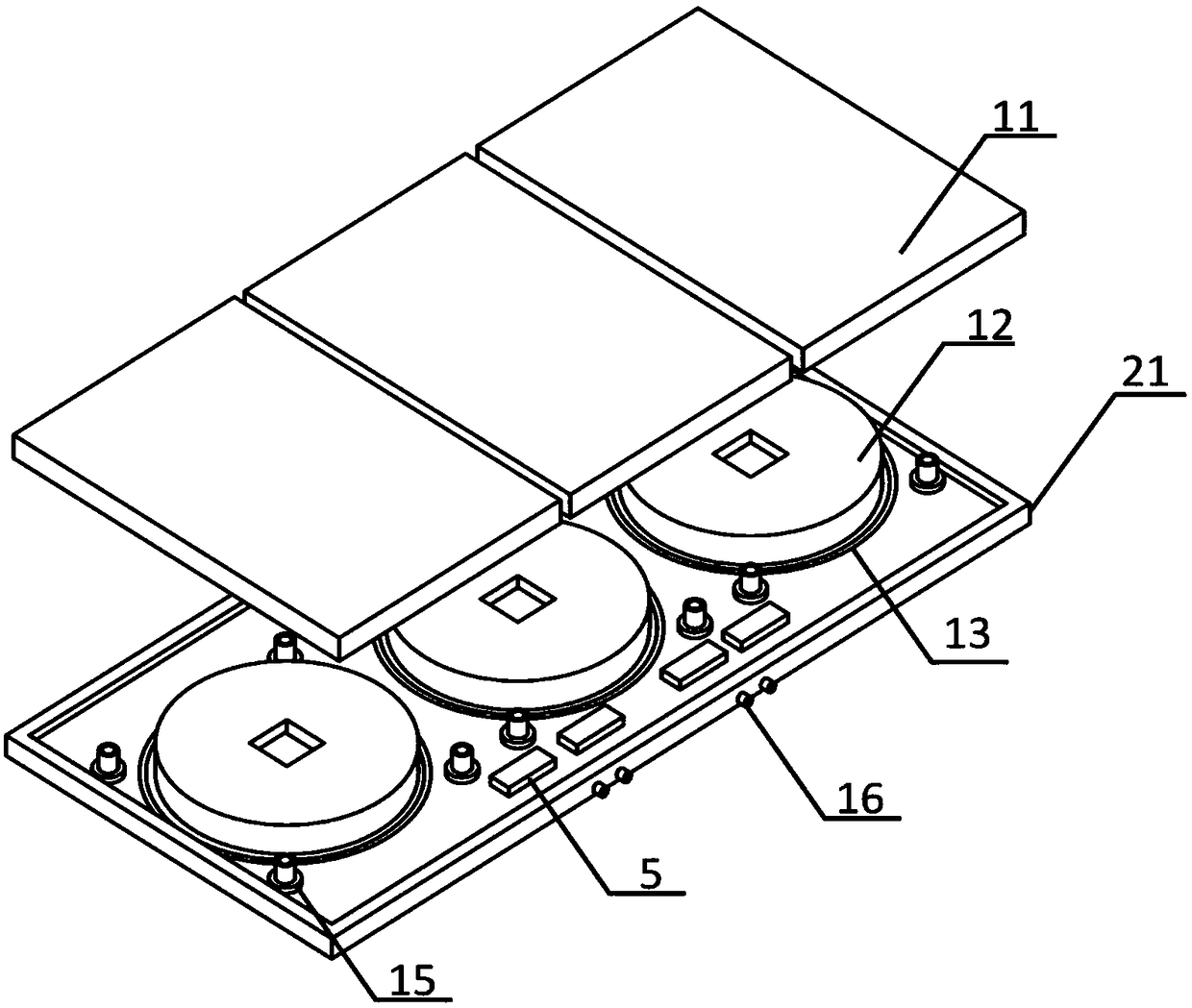

[0086] The invention constructs an optical fiber pressure sensor realized by using the optical fiber white light interference principle. In the process of application, the measurement system of the corresponding intensified quasi-distributed optical fiber pressure sensor is used. The measurement system includes a wide-spectrum light source 1, a photodetector 2, a push-pull optical path scanning system 10, a fiber coupler 3, 1×n Optical fiber splitter 5, pressure sensing box composition 6, such as Figure 4 As shown, the push-pull optical path scanning system is composed of a scanning translation stage 9, a double-sided scanning mirror 7, and an optical fiber self-focusing lens 8.

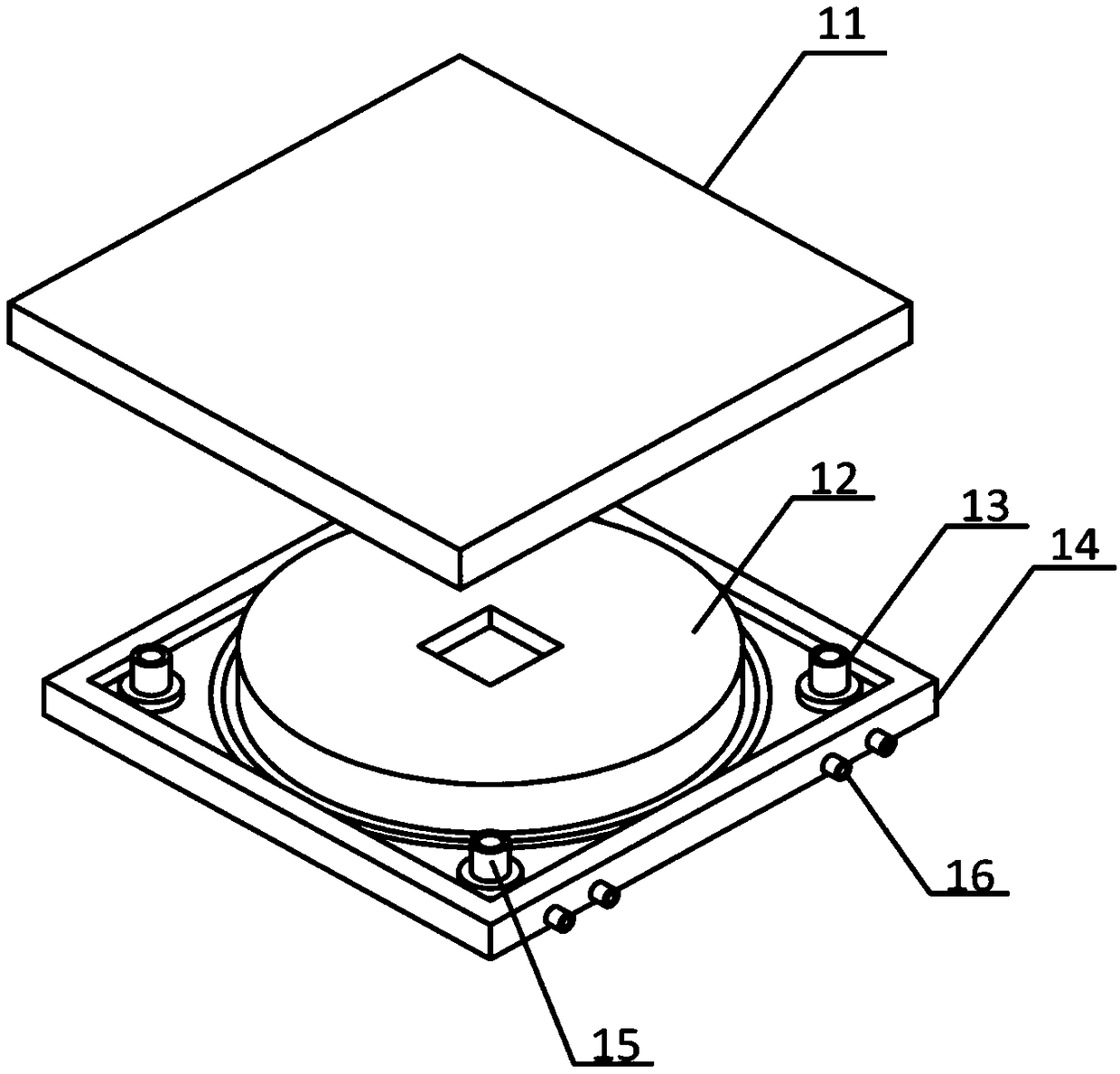

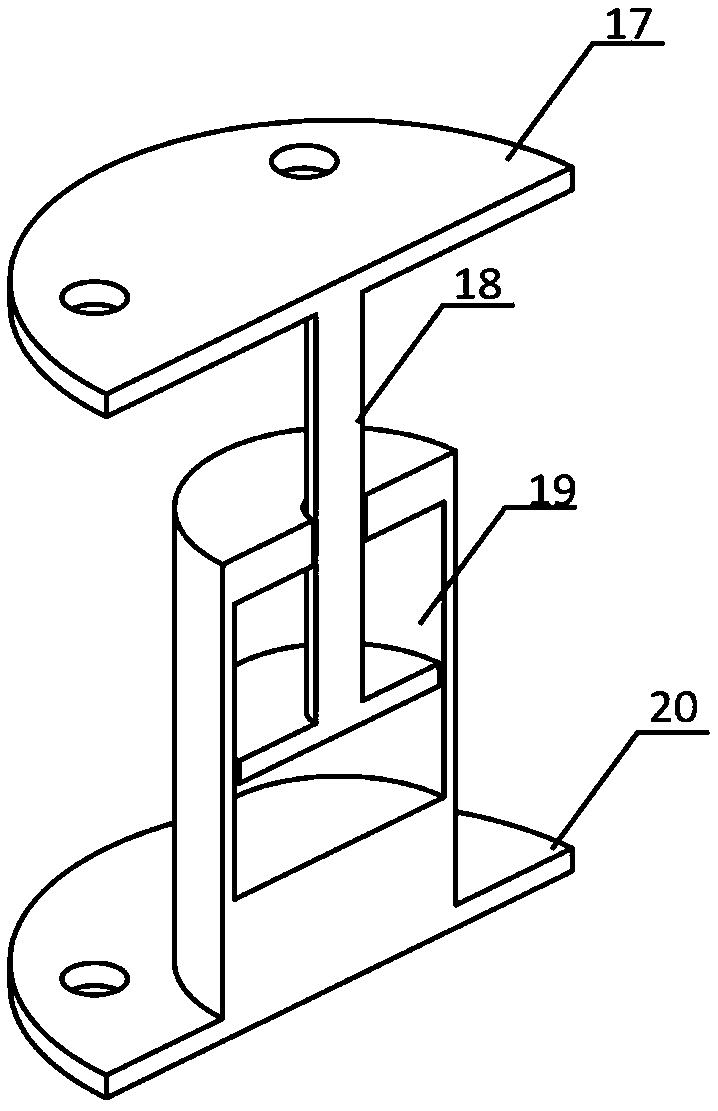

[0087] The sensitization type quasi-distributed optical fiber pressure sensor 6 includes a pressure panel 11, an elastic cylinder 12 wrapped around an optical fiber, a reference optical fiber fixing groove 13, a limit expansion rod 15, an optical fiber adapter 16, and a bottom shell 14; The cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com