Benzophenone purity standard substance and preparation method thereof

A technology for reference material and benzophenone, applied in the field of benzophenone purity reference material and its preparation, can solve the problems of differences in delivery, difficulty in arbitration of disputed data, and difficulty in data comparison, etc., to improve the consistency of comparison , fill in the research gap, reduce the effect of uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Purchase the crude product of benzophenone from the market, take 50 grams of acetonitrile to make a nearly saturated solution, and prepare sample crystals by freezing and crystallization. Cool down to -18°C at a rate of / h and keep for 48 hours. Select the single crystal particles generated in it, and make a total of about 20 grams of pure product batch by batch; dissolve it in acetonitrile, add 20-100 micrograms of BHT stabilizer at the same time, and obtain a pure product with uniform content after removing the solvent by rotary evaporation; in powder form , weighed under nitrogen protection, packed into brown storage bottles, and prepared 200 bottles in one batch;

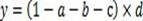

[0026] (2) Determination and uncertainty evaluation of pure benzophenone; determine the evaporation residue a of each pure product according to GB / T 9740-2008 "General Method for Determination of Evaporation Residue of Chemical Reagents"; according to GB / T 6283 "Chemical Determination of moisture con...

Embodiment 2

[0047] (1) Purchase the crude product of benzophenone from the market, take 50 grams of ethyl acetate to make a nearly saturated solution, and prepare sample crystals by freezing and crystallization. The specific conditions are: keep the refrigerator at 10°C for 2 hours, Cool at a rate of 0.2°C / h to -18°C and keep for 48 hours. Select the single crystal particles generated in it, and make a total of about 20 grams of pure products batch by batch; dissolve them in ethyl acetate, add 20-100 micrograms of BHT stabilizer at the same time, and obtain pure products with uniform content after removing the solvent by rotary evaporation; Weigh under protection, pack into brown storage bottles, and prepare 200 bottles in one batch;

[0048] (2) Determination and uncertainty evaluation of pure benzophenone; with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com