Bevel etching device and wafer etching method

A technology for etching devices and wafers, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of not being able to effectively improve wafer edge defects, and achieve uniformity, quality improvement, and uniform etching effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

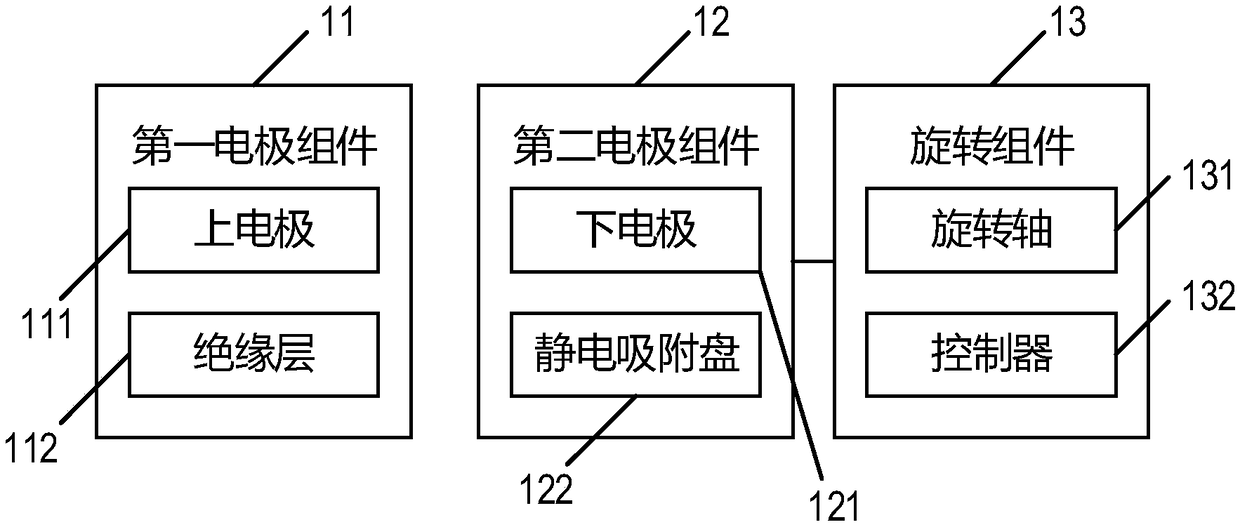

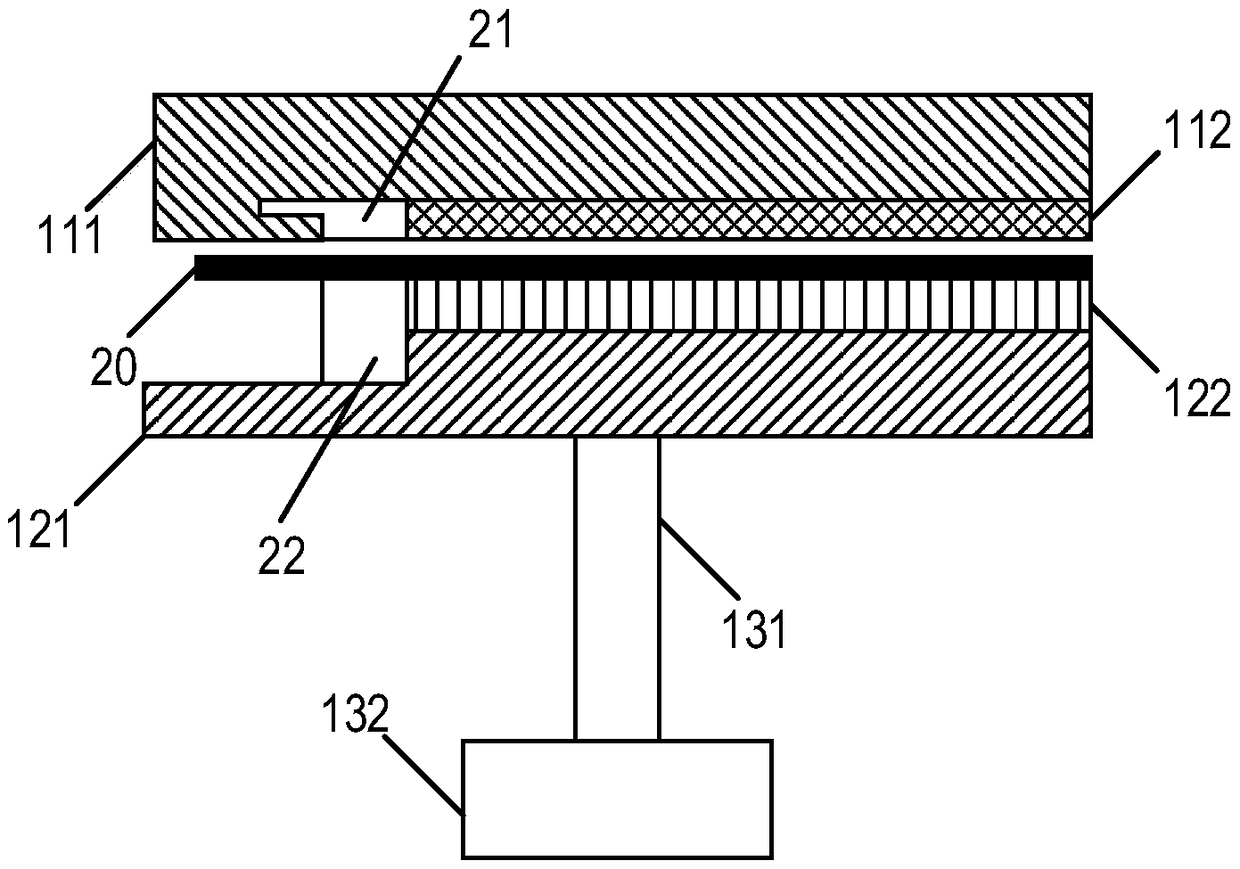

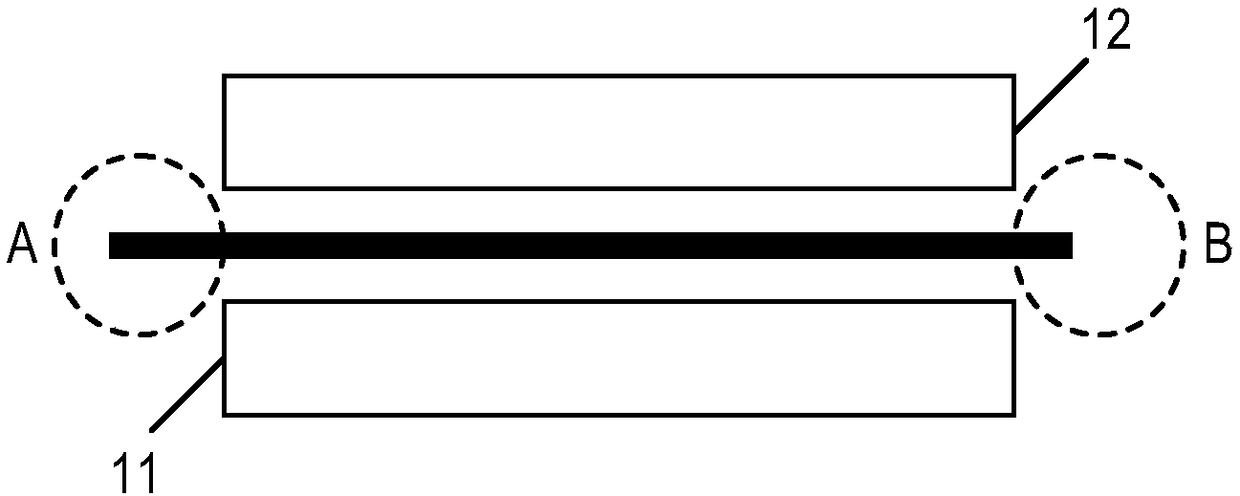

[0034] The specific implementation of the bevel etching device and the wafer etching method provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] In the semiconductor manufacturing process, after etching or other wafer processing processes, by-products will be formed at the edge of the wafer, such as polymers containing elements such as carbon, oxygen, nitrogen, and fluorine, as well as by-products due to edge effects Low quality film. These by-products exist at the edge of the wafer, which will affect the subsequent processing of the wafer. In order to ensure the quality of the wafer product, a bevel etching device is generally used to etch the edge of the wafer.

[0036] Due to the particularity of wafer edge etching, only the edge of the wafer needs to be exposed to the plasma atmosphere, and the edge of the wafer is a very small part of the wafer as a whole, such as exposed to the plasma atmosphere The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com