A fiber-based triboelectric nanogenerator with in-situ polymerization and surface modification and its preparation

A nano-generator and surface modification technology, applied in triboelectric generators, nanotechnology for materials and surface science, plant fibers, etc., can solve the problems of large material damage, high cost, complex process, etc., and achieve short preparation process , light weight and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

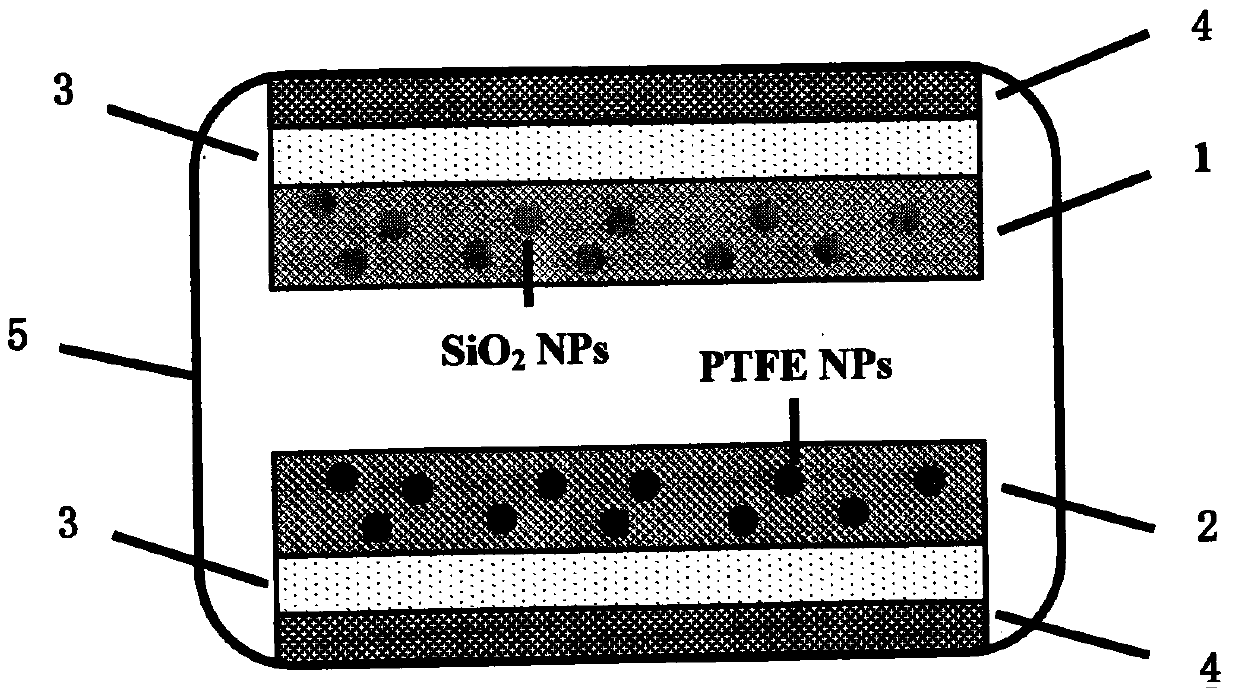

[0045] Such as figure 1 As shown, an in-situ polymerized surface-modified fiber-based triboelectric nanogenerator, including the in-situ construction of silica nanoparticles (SiO 2 NPs) triboelectrically positive nanofiber membrane 1, and surface in-situ construction of polytetrafluoroethylene nanoparticles (PTFE NPs) triboelectric negative nanofiber membrane 2; the surface in-situ construction of silica nanoparticles The triboelectrically positive nanofibrous membrane 1 and the surface of the triboelectrically negative nanofibrous membrane 2 with polytetrafluoroethylene nanoparticles constructed in situ form a multi-level micro-nano structure; the surface in situ constructed silica nanoparticles The triboelectrically positive nanofibrous membrane 1 and the back of the triboelectrically negative nanofibrous membrane 2 with polytetrafluoroethylene nanoparticles constructed in situ on the surface are all compounded with a layer of conductive material 3 as the output of the tribo...

Embodiment 2

[0055] An in-situ polymerized surface-modified fiber-based triboelectric nanogenerator, including a triboelectrically positive nanofiber film with in-situ structured silica nanoparticles on the surface, and a triboelectrically negative nanofiber film with in-situ constructed polytetrafluoroethylene nanoparticles on the surface Nanofiber membrane; the surface of the triboelectrically positive nanofiber membrane with in-situ construction of silica nanoparticles and the surface of the triboelectric negative nanofiber membrane with in-situ construction of polytetrafluoroethylene nanoparticles form multi-level micro-nano structure; the back surface of the triboelectrically positive nanofiber membrane with in-situ construction of silica nanoparticles and the triboelectric negative nanofiber membrane with in-situ construction of polytetrafluoroethylene nanoparticles on the surface are all compounded with a layer of conductive material, As the output electrode of the triboelectric nano...

Embodiment 3

[0065] An in-situ polymerized surface-modified fiber-based triboelectric nanogenerator, including a triboelectrically positive nanofiber film with in-situ structured silica nanoparticles on the surface, and a triboelectrically negative nanofiber film with in-situ constructed polytetrafluoroethylene nanoparticles on the surface Nanofibrous membrane; the triboelectrically positive nanofiber membrane with silicon dioxide nanoparticles constructed in situ on the surface, and the triboelectrically negative nanofiber membrane formed with polytetrafluoroethylene nanoparticles on the surface in situ to form multi-level microfiber membranes. nanostructure; the surface of the triboelectrically positive nanofiber membrane with silica nanoparticles constructed in situ, and the surface of the trifluoroelectric negative nanofiber membrane with polytetrafluoroethylene nanoparticles constructed in situ are all compounded with a conductive layer on the back. material, as the output electrode of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com