A polyether ether ketone fiber composite paper with electromagnetic shielding performance and preparation method thereof

A polyetheretherketone fiber and polyetheretherketone technology, which is applied in the field of polyetheretherketone fiber composite paper and its preparation, can solve the problems of low paper performance, easy agglomeration of carbon nanotubes, limited addition content, and poor paper-forming properties. , to achieve uniform conductivity, improve electromagnetic shielding performance, and good mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

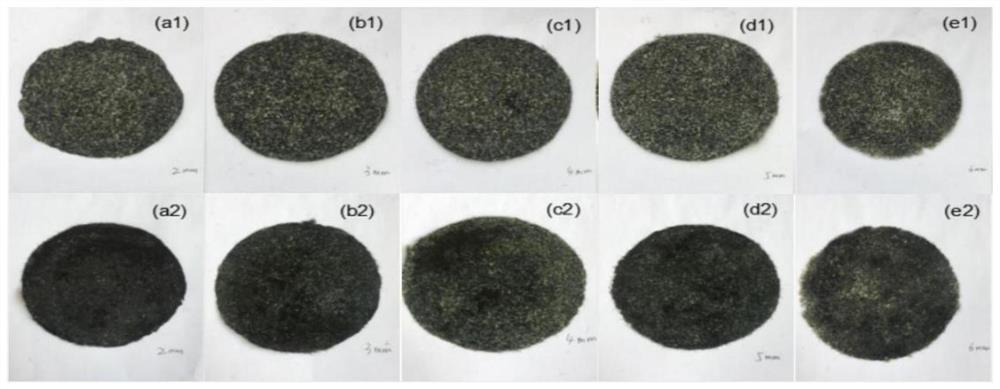

Image

Examples

preparation example Construction

[0057] The preparation method of the polyether ether ketone fiber paper with electromagnetic shielding performance of the present invention, the steps are as follows:

[0058] Step 1. Preparation of polyether ether ketone conductive fiber

[0059] 1.1 Dissolve the soluble polymer precursor of polyether ether ketone in an organic solvent first, disperse the multi-walled carbon nanotubes in the organic solvent, and then mix the two evenly by ultrasonic, add acid hydrolysis and wash to neutral ( pH=7) and then dried to obtain multi-walled carbon nanotubes coated with crystalline polyether ether ketone;

[0060] 1.2 The crystalline polyether ether ketone-coated multi-walled carbon nanotubes obtained in step 1.1 are uniformly dispersed in pure polyether ether ketone powder, and the obtained mixed powder is dried, extruded, granulated, and spun to obtain polyether ether ketone. Ether ether ketone conductive fiber;

[0061] Step 2. Preparation of polyether ether ketone fiber base p...

Embodiment 1

[0083] Step 1. Dissolve 0.4g of 1,3 dioxolane polyetheretherketone (prepared by pure polyetheretherketone with a melt index of 81g / 10min) in an organic solvent (NMP or DMAC), and dissolve 20g of multi-walled carbon nano Disperse the tube (length 1-2μm) in an organic solvent (NMP or DMAC), and then mix the two evenly by ultrasonic, add 24mL concentrated hydrochloric acid (mass fraction: 35%) for hydrolysis, wash with water to pH=7, and then dry to obtain crystalline Multi-walled carbon nanotubes coated with polyether ether ketone;

[0084] Disperse 5g of crystalline polyetheretherketone-coated multi-walled carbon nanotubes uniformly in 495g of pure polyetheretherketone powder (melt index: 81g / 10min), dry in an oven at 120°C for 2h-4h, and use a twin-screw to rotate Moment rheometer extrusion granulation, the dried pellets are added to the high-temperature spinning machine, the pellets are melted and plasticized in the barrel of the extruder, and then enter the melt metering pum...

Embodiment 2

[0090] Embodiment 2 chooses the fiber segment of 3mm, 6mm length, joins respectively to concentration and is 1.5 * 10 -3 mol / L Triton X-100 solution, stirring to loosen and disperse the fibers into a single state, and then drying to obtain polyether ether ketone conductive fiber segments. Disperse the mass ratio of 3mm polyetheretherketone conductive fiber segment: 6mm polyether ether ketone conductive fiber segment: aramid 1313 fiber = 40%: 52%: 8% in 0.02% polyethylene oxide polywater solution, stirring at 4000 rpm After 75 minutes, fiber slurry was obtained. The rest of the preparation of polyetheretherketone fiber composite paper in Example 2 is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com