A cavity system with high uniformity and low temperature coefficient

A technology with low temperature coefficient and uniformity, applied in electrical components, automatic control of power, output stability, etc., can solve the problems of high temperature coefficient of microwave cavity, difficult repeated processing, difficult surface polishing, etc., to improve the signal-to-noise ratio , Improve the filling factor and direction factor, and the effect of axial magnetic field uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

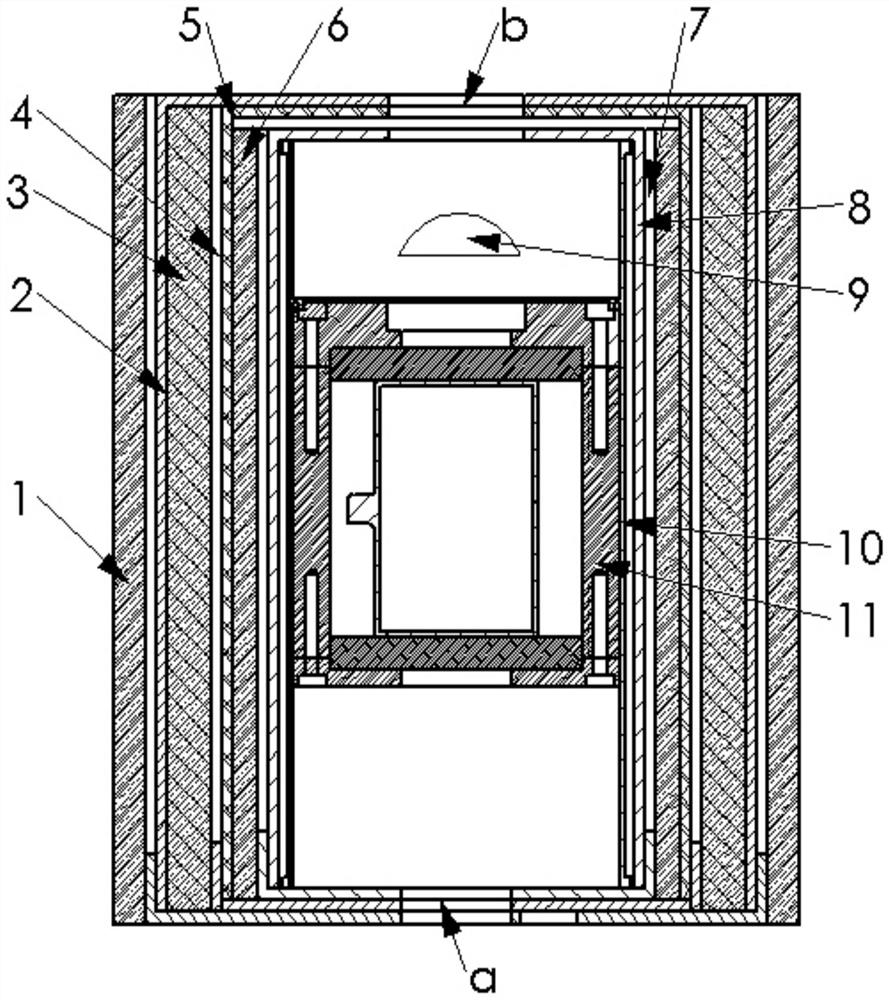

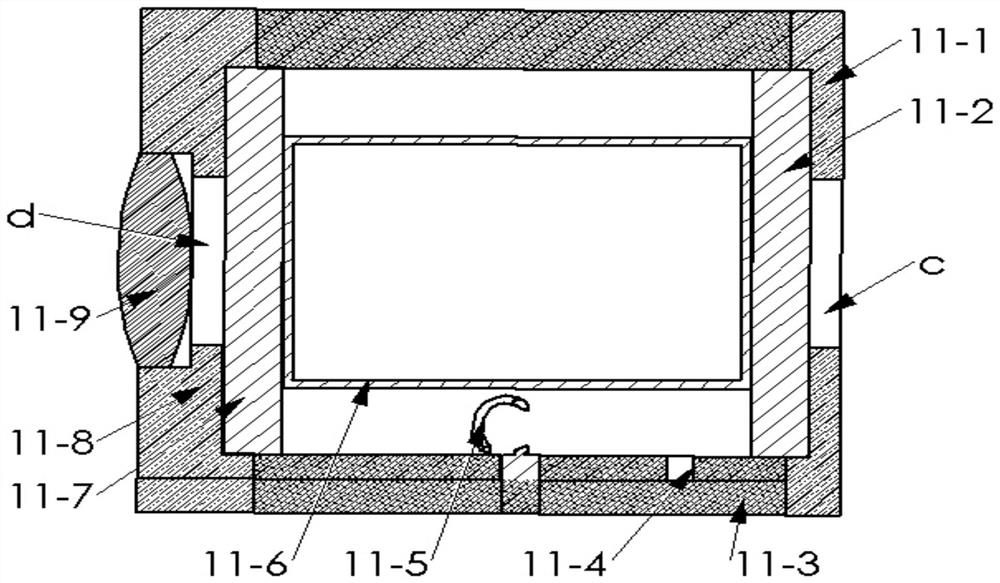

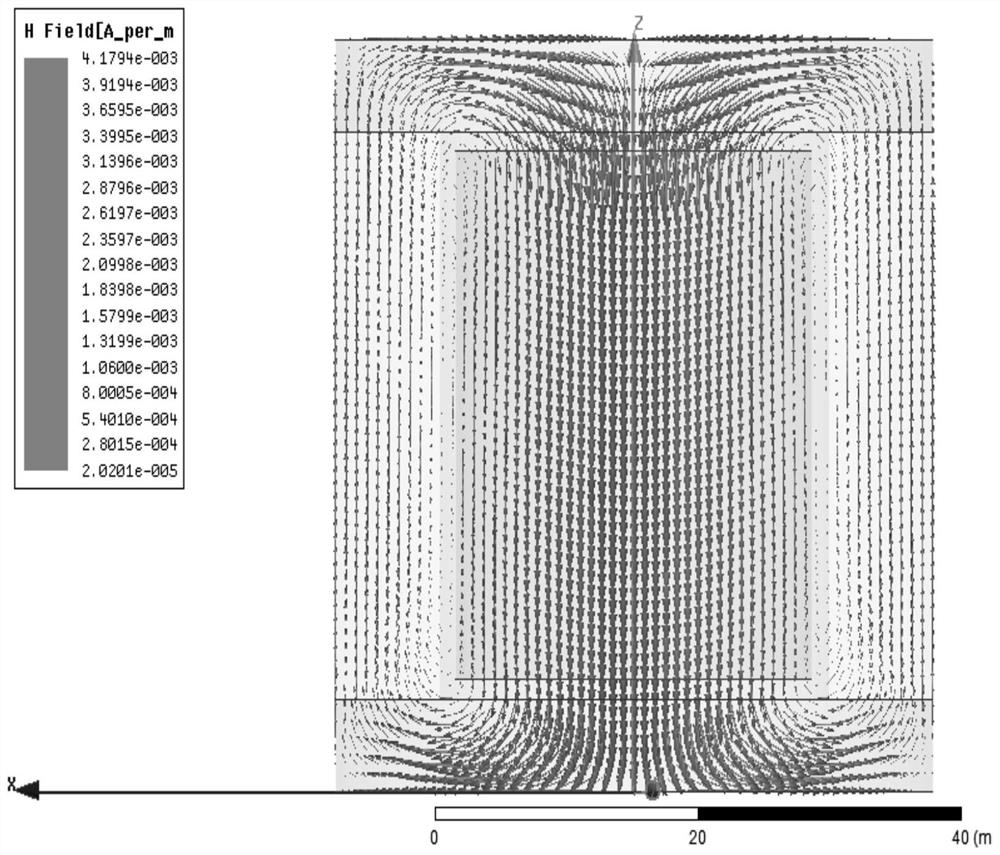

[0033] exist figure 1 Among them, the present invention is a cavity system with high uniformity and low temperature coefficient. The system consists of outer thermal insulation layer 1, outer magnetic shielding cylinder 2, middle thermal insulation layer 3, outer heating cylinder 4, middle Magnetic shielding cylinder 5, inner thermal insulation layer 6, inner heating cylinder 7, inner magnetic shielding cylinder 8, detector 9, C field coil 10, microwave resonant cavity 11. The thermal insulation layer is polyurethane or thermal insulation material coated with reflective tin film, which is wrapped on the outside of the heating layer to insulate the physical system; the heating cylinder is an aluminum cylinder with twisted twisted The resistance heating wire heats the entire physical system by controlling the current of the heating wire, and the residual magnetic field generated by the heating current can be eliminated as much as possible by using a twisted pair; the C field coi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com