Microwave heating device adopting phase scanning

A microwave heating device and phase scanning technology, applied in the microwave field, can solve the problems of different free spaces, analysis modes, material dielectric properties and complex shapes, etc., to achieve the effect of large power capacity and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

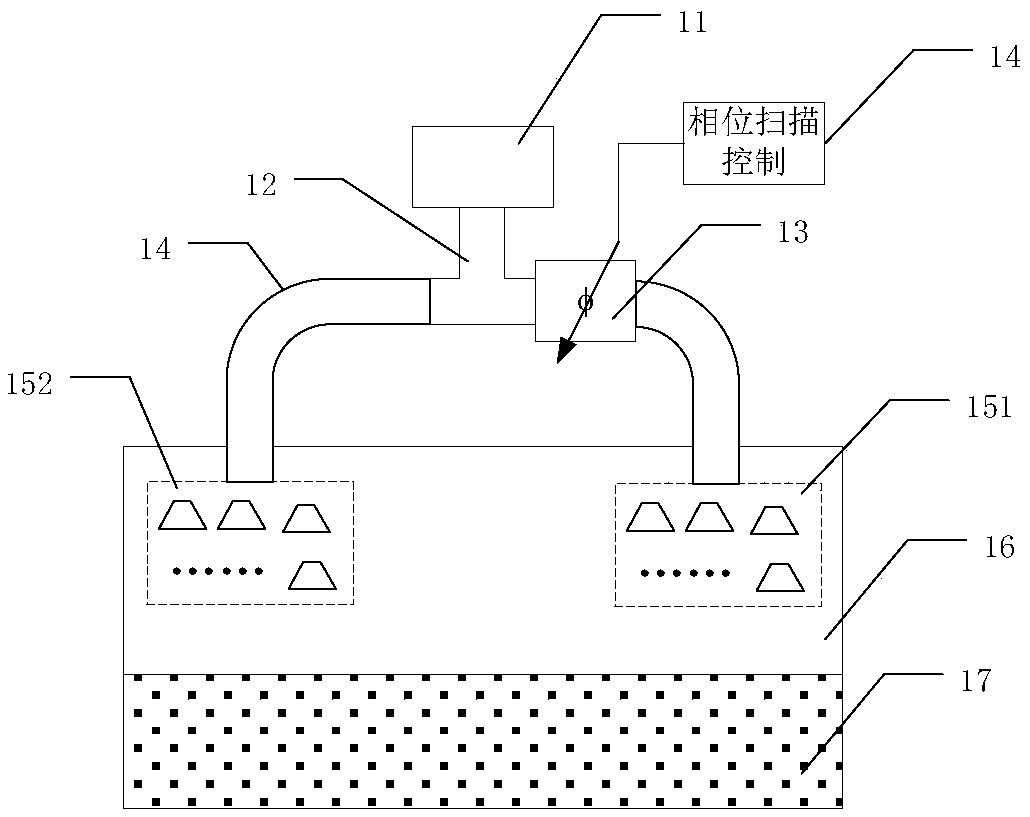

[0029] A microwave heating device using phase scanning of the present invention, the principle is as follows figure 1 As shown, it includes a microwave generator 11 , a waveguide power divider 12 , a waveguide phase shifter 13 , a phase scanning control system 14 , a microwave antenna 15 , a microwave application cavity 16 and a material 17 .

[0030] The microwave power generated by microwave generator 11 is distributed into N (N≥2) road outputs through waveguide power divider 12, wherein at least one road output is connected with waveguide phase shifter 13; microwave antenna 15 is divided into N groups, wherein a group of microwave antennas The input of 151 is connected to the output of waveguide phase shifter 13 , and the input of other groups of microwave antennas 152 is directly connected to the output port of waveguide power divider 12 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com