Winter pig house ventilation system for large-scale pig farm

A technology for ventilation system and pig house, which is applied in animal houses, applications, animal husbandry, etc., can solve the problems of large differences in air freshness, uneven air flow rate in the house, and poor air quality, and achieves simple use and solution. The contradiction between warmth and ventilation, the effect of reducing the concentration of ammonia gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

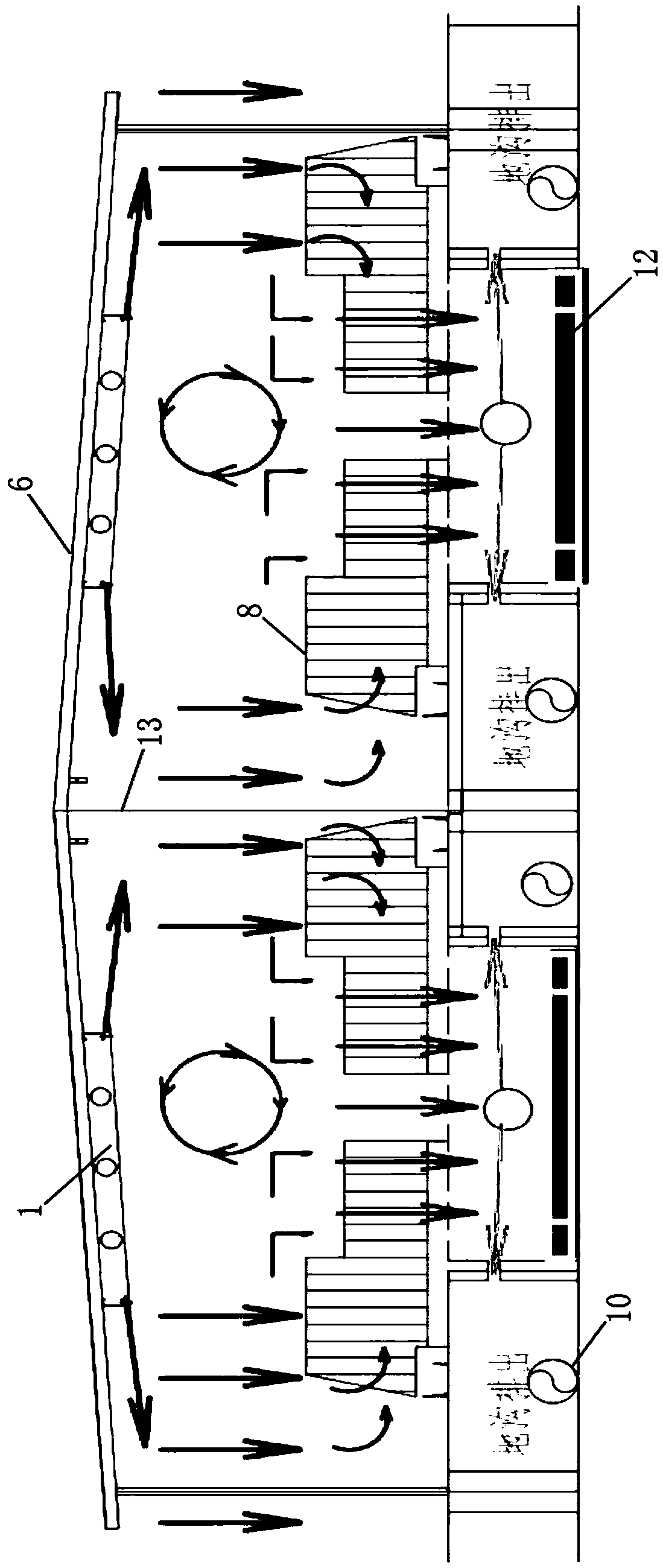

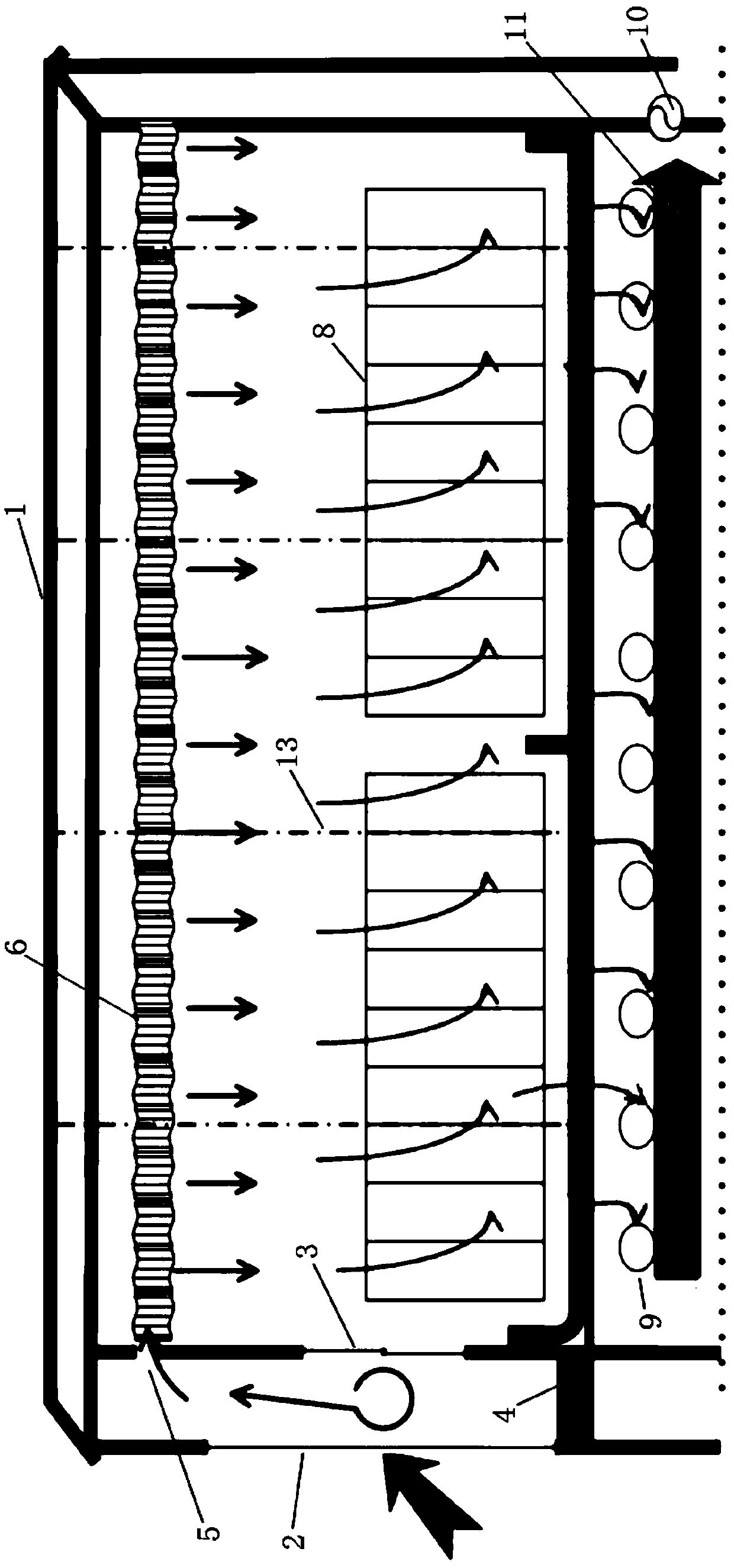

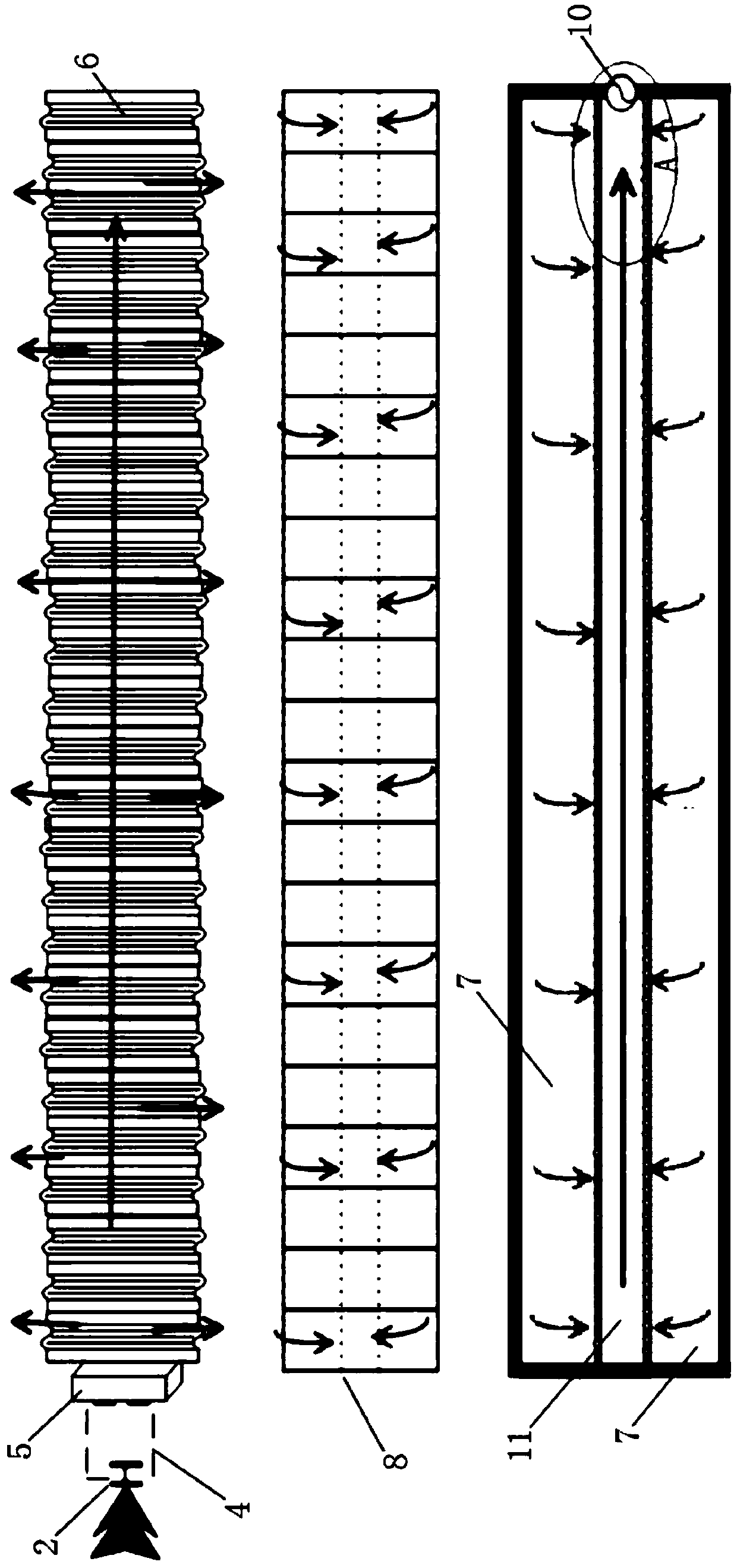

[0024] Such as Figure 1-4 As shown, the winter pig house ventilation system for large-scale pig farms provided by the present invention is ingenious in design, easy to use, and reliable, and is suitable for large-scale pig farms in winter, late autumn, and early spring when the temperature is low and the temperature changes quickly. Ventilation management in pig houses can reduce the concentration of harmful gases such as ammonia and hydrogen sulfide in the house, improve pig health and feed-to-meat ratio, improve work efficiency, and reduce breeding costs. The invention comprises a herringbone pig house roof 1 arranged on the top of the pig house, and a wet curtain 2, a central walkway 4, an air inlet 5, a deflector plate 6, a pig pen 8, and a row of pig houses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com