Cigarette microcapsule with cool and sweet flavor and preparation method and application thereof

A technology for microcapsules and cigarettes, applied in the directions of application and preparation of tobacco, tobacco, etc., can solve the problems of loss, unsuitability of menthyl acetate cigarettes, inability to guarantee the quality stability of cigarette products, etc., and achieves reduced irritation and improved The effect of smoking satisfaction and pleasure, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

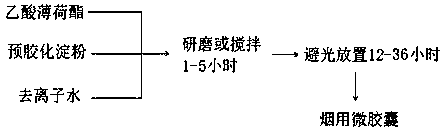

[0016] Such as figure 1 As shown, the preparation method of the microcapsules for tobacco with cool and sweet fragrance of the present embodiment is carried out as follows:

[0017] Pipette 3% menthyl acetate, 50% pregelatinized starch, and 47% deionized water to mix, grind at room temperature for 1 hour until it becomes a paste, place it in a dark and cool place, and leave it open for 12 hours , to obtain microcapsules for tobacco.

[0018] The above-mentioned microcapsules for tobacco were added to the cigarette forming paper in an amount of 2 mg / 100 g of forming paper, and the cigarette sample was rolled with Hongtashan (1956) leaves, and the remaining auxiliary materials and additives were kept unchanged, and the cigarette sample A was prepared. Hongtashan (1956) products were compared and evaluated, and found that the aroma quality increased by 3%, the irritation decreased by 2%, and the cool and sweet aroma increased by 1%, with better smoking consistency.

[0019] As ...

Embodiment 2

[0021] The preparation method of the microcapsules for tobacco with cool and sweet fragrance of the present embodiment is carried out as follows:

[0022] Pipette 13% menthyl acetate, 60% pregelatinized starch, and 27% deionized water to mix, grind at room temperature for 4 hours until it becomes a paste, place it in a dark and cool place, and leave it open for 36 hours , to obtain microcapsules for tobacco.

[0023] The above-mentioned microcapsules for tobacco were added to the cigarette forming paper in an amount of 6 mg / 100 g of forming paper, and a cigarette sample was rolled with Hongtashan (1956) leaves, and the remaining auxiliary materials and additives were kept unchanged to prepare cigarette sample B. Compared with Hongtashan (1956) products, it was found that the aroma richness increased by 6%, the irritation decreased by 8%, and the cool-sweet aroma increased by 5%, with better smoking consistency.

[0024] As a comparison, the additive prepared by CN20161117074....

Embodiment 3

[0026] The preparation method of the microcapsules for tobacco with cool and sweet fragrance of the present embodiment is carried out as follows:

[0027] Pipette 8% by mass of menthyl acetate, 55% of pregelatinized starch, and 37% of deionized water to mix, grind at room temperature for 3 hours until it becomes a paste, place it in a dark and cool place, and leave it open for 24 hours , to obtain microcapsules for tobacco.

[0028] The above-mentioned microcapsules for tobacco were added to the cigarette forming paper in an amount of 12 mg / 100 g of forming paper, and the cigarette sample was rolled by Hongtashan (1956) leaf group, and the remaining auxiliary materials and additives were kept unchanged, and the cigarette sample C was prepared. Hongtashan (1956) products were compared and evaluated, and found that the richness of aroma increased by 2%, the irritation decreased by 0.5%, and the cool and sweet aroma increased by 8%, which has a good smoking consistency.

[0029]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com